- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

Customers Local Voltage

-

Power:

-

5.5kw

-

Weight (KG):

-

30

-

Workpiece:

-

Gas cylinder

-

Workpiece material:

-

Metal

-

Max. workpiece size:

-

300xH570(mm)

-

Workpiece weight:

-

≤30kg

-

Braced chain:

-

QXT250/50Kg light common chain

-

Machine capacity:

-

2000pcs/12hours

-

Hanging type:

-

One cylinder every two pitch, that means one cylinder per 500mm.

-

Linear speed:

-

2000pcs/12h/60minx0.5m/hang=1.4m/min

-

Heating source:

-

Nature gas(LPG)

-

Location area:

-

See layout drawing, beam bottom height 8.5 meters

Quick Details

-

Machine Type:

-

powder coating plant, Curing oven

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

HS

-

Voltage:

-

Customers Local Voltage

-

Power:

-

5.5kw

-

Weight (KG):

-

30

-

Workpiece:

-

Gas cylinder

-

Workpiece material:

-

Metal

-

Max. workpiece size:

-

300xH570(mm)

-

Workpiece weight:

-

≤30kg

-

Braced chain:

-

QXT250/50Kg light common chain

-

Machine capacity:

-

2000pcs/12hours

-

Hanging type:

-

One cylinder every two pitch, that means one cylinder per 500mm.

-

Linear speed:

-

2000pcs/12h/60minx0.5m/hang=1.4m/min

-

Heating source:

-

Nature gas(LPG)

-

Location area:

-

See layout drawing, beam bottom height 8.5 meters

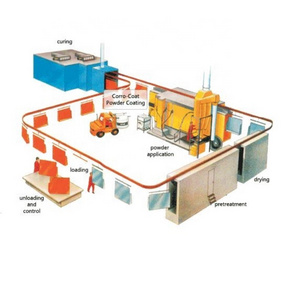

Product Overview

Process flow diagram

This line consists of powder coating chamber, booth, curing bake, suspend conveyor and electric control system.

This line consists of powder coating chamber, booth, curing bake, suspend conveyor and electric control system.

|

No

|

Name

|

Transit time

|

Working temperature

|

Operation

|

|

1

|

Loading

|

|

RT

|

Manual

|

|

2

|

Powder coating

|

|

RT

|

Auto+manual

|

|

3

|

baking

|

17-18min

|

180-190ºC

|

Heated air circle

|

|

4

|

cooling

|

20min

|

|

|

|

5

|

unloading

|

|

|

Manual

|

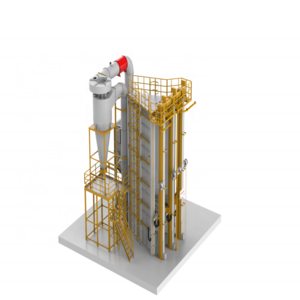

Curing bake

The drying tunnel consists of three parts: drying tunnel. Heating system and exhaust system.

3.1 Drying tunnel

The drying tunnel consists of three parts: drying tunnel. Heating system and exhaust system.

3.1 Drying tunnel

|

No

|

Name

|

Technical parameter

|

|

1

|

Overall structure

|

Bridge type

|

|

2

|

No of tunnels

|

4

|

|

3

|

Size of the inner tunnel

|

L14×W3.2×H2.1(m). Leg height 2.5meters

|

|

4

|

Thickness of the insulation

|

150mm

|

|

5

|

Material of the insulation

|

High quality rock wool board

|

|

6

|

Unit weight of the insulation

|

100Kg/m3

|

|

7

|

Material of the inner plate

|

δ0.8 galvanized steel sheet

|

|

8

|

Metarial of the outer plate

|

δ0.8 color sheet

|

|

9

|

Structure of inner and outer plate

|

Assembly structure

|

|

10

|

Material of the inner angle plate

|

δ1 galvanized steel sheet

|

|

11

|

Material of the outer angle plate

|

δ3 hot-rolled sheet with paint

|

|

12

|

Supporter material of the tunnel

|

δ3 carbon steel sheet, edgefold with paint

|

|

13

|

Outer temperature of the tunnel

|

Lower than environment temperature 15ºC

|

|

14

|

Inner temperature of the tunnel

|

180ºC

|

|

15

|

Drain cracking-off

|

Top of the tunnel

|

3.2. heating system

consists of heating chamber, burner, heated air recycling fan, return airway and temperature control system.

(1)heating room

(1)heating room

an access door is on the side of the heating chamber for future repairing.

|

No

|

Name

|

Technical parameter

|

|

1

|

Position and number of heating room

|

Bottom of the bake tunnel, 1 set

|

|

2

|

Heating room configuration

|

300000 calories, 1 set

|

|

3

|

Inner plate of the heating room

|

Galvanized steel, δ1

|

|

4

|

Outer plate of the heating room

|

Cold-roll steel sheet, δ1.5

|

|

5

|

Thickness of the insulation

|

150mm

|

|

6

|

Material of the insulation

|

High quality rock wool board

|

|

7

|

Unit weight of the insulation

|

100Kg/m3

|

|

8

|

Material of the inner angle plate

|

δ1 galvanized steel sheet

|

|

9

|

Material of the outer angle plate

|

δ3 hot-rolled sheet with paint

|

|

10

|

Supporter material of the tunnel

|

δ3 carbon steel sheet, edgefold with paint

|

|

11

|

Structure of inner and outer plate

|

Assembly structure

|

(2) burner

1 set, 300000 calories

Gas consumption: 10-15m3/h

Brand: Italian Riello RS34

(3)burning tank

Heat exchanger is used to transfer the heat to heating room, then hot-air blower will bring the heat to the tunnel. Adopts

direct-fired heating, the burning tank is stainless steel with high temperature filter.

(4)Thermal cycling fan

1 set, 300000 calories

Gas consumption: 10-15m3/h

Brand: Italian Riello RS34

(3)burning tank

Heat exchanger is used to transfer the heat to heating room, then hot-air blower will bring the heat to the tunnel. Adopts

direct-fired heating, the burning tank is stainless steel with high temperature filter.

(4)Thermal cycling fan

adopts special air-cooled centrifugal fan

|

No

|

Name

|

Parameter

|

|

1

|

Model

|

GCF-630C

|

|

2

|

Rotation speed

|

1250r/min

|

|

3

|

Air flow volume

|

13500m3/h

|

|

4

|

Total pressure

|

900Pα

|

|

5

|

Motor power

|

5.5KW

|

|

6

|

Fan structure

|

Impeller is in the heating room

|

|

7

|

Insulation thickness

|

150mm

|

|

9

|

Impeller material

|

16Mn

|

|

10

|

No. Of fans

|

1 set

|

|

11

|

Fans supplier

|

Shanghai Shuyuan or Kewangda

|

(5) Air delivery & returning duct

|

No

|

Name

|

Parameter

|

|

1

|

Hot air recycling

|

Internal recycle, no outer tubes

|

|

2

|

Air delivery type

|

Under floor air delivery

|

|

3

|

Air returning type

|

Under floor air returning

|

|

4

|

Duct material

|

Galvanized steelδ1

|

|

5

|

No of air regulation plate

|

1 set

|

|

6

|

Material of air regulation plate

|

Galvanized steelδ1

|

(6) Temperature control system

Drying tunnel uses digital temperature controller to adjust the temperature automatically, it can display and control the drying tunnel temperature in real-time.

The temperature measurement uses platinum resistor temperature sensor.

The drying tunnel temperature can be adjusted continuously from normal temperature to 200°C.

3.3. Exhaust pipe

The entrance/exit of the drying tunnel on the top equips with exhaust pipe and butterfly valve, it is used for draining the

exhaust gas of the drying tunnel.

The material of the exhaust pipe is δ1mm galvanized sheet.

Drying tunnel uses digital temperature controller to adjust the temperature automatically, it can display and control the drying tunnel temperature in real-time.

The temperature measurement uses platinum resistor temperature sensor.

The drying tunnel temperature can be adjusted continuously from normal temperature to 200°C.

3.3. Exhaust pipe

The entrance/exit of the drying tunnel on the top equips with exhaust pipe and butterfly valve, it is used for draining the

exhaust gas of the drying tunnel.

The material of the exhaust pipe is δ1mm galvanized sheet.

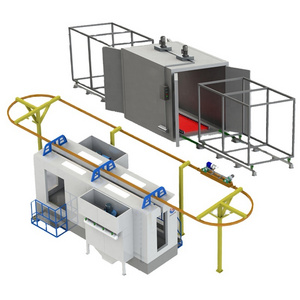

Hang type conveyor

Hang type conveyor consist of driving device, tension device, variable-frequency governor, chain, straight conveyor, bend

conveyor, temperature flexible conveyor, inspection conveyor and lubrication system etc.

Variable -frequency governor uses Mitsubishi. The speed is 1.4 m/min.

The lubrication system uses automatic oil drop device.

Hang type conveyor equips with 1 set driving device, 1 set weight-loaded type tension device, using frequency to adjust speed.

Hang type conveyor consist of driving device, tension device, variable-frequency governor, chain, straight conveyor, bend

conveyor, temperature flexible conveyor, inspection conveyor and lubrication system etc.

Variable -frequency governor uses Mitsubishi. The speed is 1.4 m/min.

The lubrication system uses automatic oil drop device.

Hang type conveyor equips with 1 set driving device, 1 set weight-loaded type tension device, using frequency to adjust speed.

|

No

|

Name

|

Technical specification

|

|

1

|

Driving device model

|

QXT-250

|

|

2

|

Driving device quantity

|

1 set

|

|

3

|

Overload protection for driving device

|

Adjustable safety clutch+travel switch

|

|

4

|

Driving device power

|

3.0KW

|

|

5

|

Tension device type

|

Weight-loaded type

|

|

6

|

Tension device quantity

|

1set

|

|

7

|

Turning radius of tension device

|

≥R800(mm)

|

|

8

|

Frequency converter

|

Mitsubishi 1 set

|

|

9

|

Conveyor chain length

|

125m

|

|

10

|

Conveyor chain pitch

|

250mm

|

|

11

|

Hoisting weight of conveyor chain single point

|

50Kg

|

|

12

|

Production speed

|

1.4m/min

|

|

13

|

Production speed adjustable method

|

Frequency control(0.6-2.0m/min)

|

|

14

|

Column quantity,material

|

Complete set, steel section

|

|

15

|

Bottom plate quantity,material

|

Complete set, hot-rolled sheet steel

|

|

16

|

Beam quantity,material

|

Complete set, steel section

|

|

17

|

Diagonal bracing quantity,material

|

Complete set, steel section

|

|

18

|

lubrication system

|

Automatic oil drop device 1 set

|

|

19

|

"C" type jig and rotary rack

|

250 pcs

|

|

20

|

Rotary rack

|

1set

|

Powder coating system

5.1. Technical parameter

5.1. Technical parameter

|

Machine type

|

Manual

|

|

Max. Hang range of the workpiece

|

W310xH570

|

|

Conveyor speed

|

About 1.4m/min

|

|

Type of conveyor

|

Suspend conveyor

|

|

Coating material

|

Polyester powder and epoxy powder |

|

Color

|

2 kinds

|

|

Powder supplier

|

Local |

|

Type of coating chamber

|

Filter type powder coating chamber |

|

Type of powder coating systems

|

Corona torch |

|

No of powder coating systems

|

6 sets auto, 1 set manual spraying torch |

|

Type of hoister

|

Reciprocating hoister |

|

No of hoister

|

1 set

|

|

No of the torch on the hoister

|

2 sets on left, 2 sets on top, 2 sets on bottom

|

|

Suction capacity of coating chamber

|

11000 m3/h

|

|

Required pressure for compressed air

|

6 - 8 bar , + 0.1 bar |

|

Remaining water in the compressed air

|

Max. 1.3 g/N m3 |

|

Remaining oil in the compressed air

|

Max. 0.1 mg/N m3

|

|

Estimated air consumption for chamber

|

120 N m3/h |

|

Power supply

|

220/380 VAC, 50Hz, 3L/N/PE, 3 phase 5 wires

|

|

Estimated power consumption for powder coating

|

Approx. 10 KVA |

|

Estimated power consumption for chamber

|

15KVA -- powder coating chamber |

|

Requirement for operation condition

|

Relative humidity<80%

Ambient temperature< 30ºC Air speed near the chamber< 0.1 m/sec |

FEATURES AT A GLANCE

SALES AND SERVICE NETWORK

Hot Searches