- Product Details

- {{item.text}}

Quick Details

-

Core Components:

-

Rolling mill

-

Voltage:

-

380V

-

Power:

-

280KW

-

Dimension(L*W*H):

-

not standard

-

Weight (KG):

-

5000

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

name:

-

small hot rolling mill

-

capacity:

-

1-5t per hour

-

certificate:

-

CE,ISO9001

-

Raw material:

-

scrap steel/billets

-

final rebar size:

-

8-32mm

-

Finished product:

-

8-32mm Bar

-

Material:

-

steel iron

-

Rolling type:

-

Semi Continuous Rolling

-

Rebar type:

-

Straight

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

HONGTENG

-

Marketing Type:

-

New Product 2024

-

Core Components:

-

Rolling mill

-

Voltage:

-

380V

-

Power:

-

280KW

-

Dimension(L*W*H):

-

not standard

-

Weight (KG):

-

5000

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

name:

-

small hot rolling mill

-

capacity:

-

1-5t per hour

-

certificate:

-

CE,ISO9001

-

Raw material:

-

scrap steel/billets

-

final rebar size:

-

8-32mm

-

Finished product:

-

8-32mm Bar

-

Material:

-

steel iron

-

Rolling type:

-

Semi Continuous Rolling

-

Rebar type:

-

Straight

We are factory(

more than 15years experiences

) located in Luoyang, Henan provice, China.

We are a professional manufacturer of

Hot rolling mill, CCM and Industrial electric furnace

.

We can provide a total solution according to your request.

We can provide CE Certificate , Overseas installation and After-sales service.

You are welcome to send us enquiry or to visit our factory.

We can provide a total solution according to your request.

We can provide CE Certificate , Overseas installation and After-sales service.

You are welcome to send us enquiry or to visit our factory.

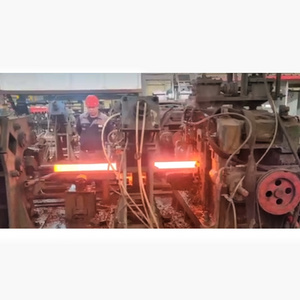

Product Show

Hot rolling mill is mainly used in iron and steel plants to produce special-shaped bars, wires, channel steel, flat bars, steel plates and other products.

Hot rolling production lines for deformed bars are divided into continuous rolling and semi-continuous rolling. The rolling type of continuous rolling is double groove and single line. It can reduce furnace scaling caused by secondary heating and improve the finished product rate by 0.3 ~ 0.5%.

1, Compared with the traditional production method,

the direct rolling of billet hot charging reduces the billet storage process, reduces the storage area and saves the investment.

2, Hot charging and direct rolling of billets do not require reheating of cold billets before rolling.

So that that yield can be improve, the energy consumption can be reduced, and the production cost can be reduce

Project site

Product Advantages

1. The small production capacity of 3t/h, 5t/h, 10t/h and 15t/h is the standard product of our company.

2. That diameter of the steel bar of the final product: 6.5-32mm, the square steel bar: 100*100, 150*150, and the length: 3000-6000mm

3. Adopt numerical control system, that production is divided into six zone: melting zone, casting zone, heating zone, rolling zone, cooling zone and collecting zone

4. Provide overall solution and after-sales guarantee

--Provide plant design, proposal, manufacturing, shipping, installation and commissioning services

-Provide factory building design, overall equipment layout, rolling mill process design, electrical circuit layout and other services.

---Dispatch technicians to provide installation services after the machine arrives until the customer is satisfied

-Long-term technical support, long-term machine warranty

|

Specification and Technical Parameter

|

|

|

|

|

||||

|

Model

|

Power (KW)

|

Rolling Speed(M/S)

|

Feed section (MM)

|

Rolling specification

|

||||

|

H200-2

|

90

|

1.5

|

30*30

|

Ø10-16

|

||||

|

H220-2

|

95

|

1.5-2

|

40*40

|

Ø10-24

|

||||

|

H250-3

|

180

|

1.8-2.5

|

50*50

|

Ø8-32

|

||||

|

H250-4

|

315/240

|

2.5-4

|

60*60

|

Ø8-32

|

||||

|

H250-5

|

500

|

2.5-5

|

50*50

|

Ø6.5-32

|

||||

|

H280-5

|

630

|

2-2.5

|

70*70

|

Ø6.5-32

|

||||

|

H300-5

|

680

|

2-2.5

|

90*90

|

Ø6.5-32

|

||||

|

H350-5

|

800

|

2-2.5

|

90*90

|

Ø6.5-32

|

||||

Recommend Products

Why Choose Us

We can give customer one APP account, Customer can use their phone or computer to view order progress in real time

Certifications

Product packaging

Hot Searches