- Product Details

- {{item.text}}

Quick Details

-

Power:

-

11000

-

Place of Origin:

-

Zhejiang, China

-

Dimension(L*W*H):

-

2530mm*2230mm

-

Weight:

-

423 KG

-

Product name:

-

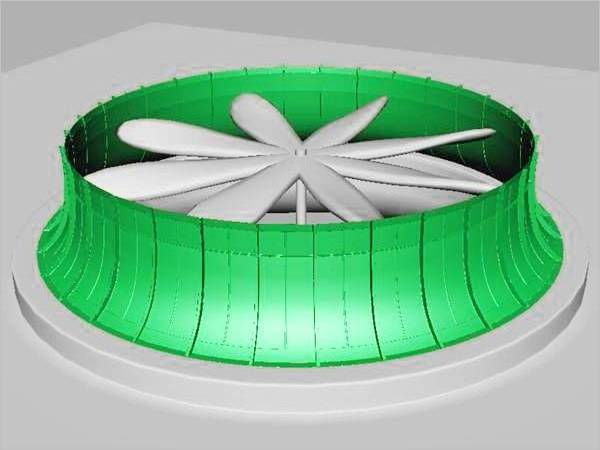

FRP GRP Cooling Tower

-

Type:

-

Counter Flow Closed Cooling Tower

-

Application:

-

Industrial Fluids Cooling

-

Shape:

-

Round.square

-

Usage:

-

Cooing Tower

-

After Warranty Service:

-

Video technical support, Online support

-

Local Service Location:

-

None

-

After-sales Service Provided:

-

Free spare parts

Quick Details

-

Cooling Type:

-

Counter Flow

-

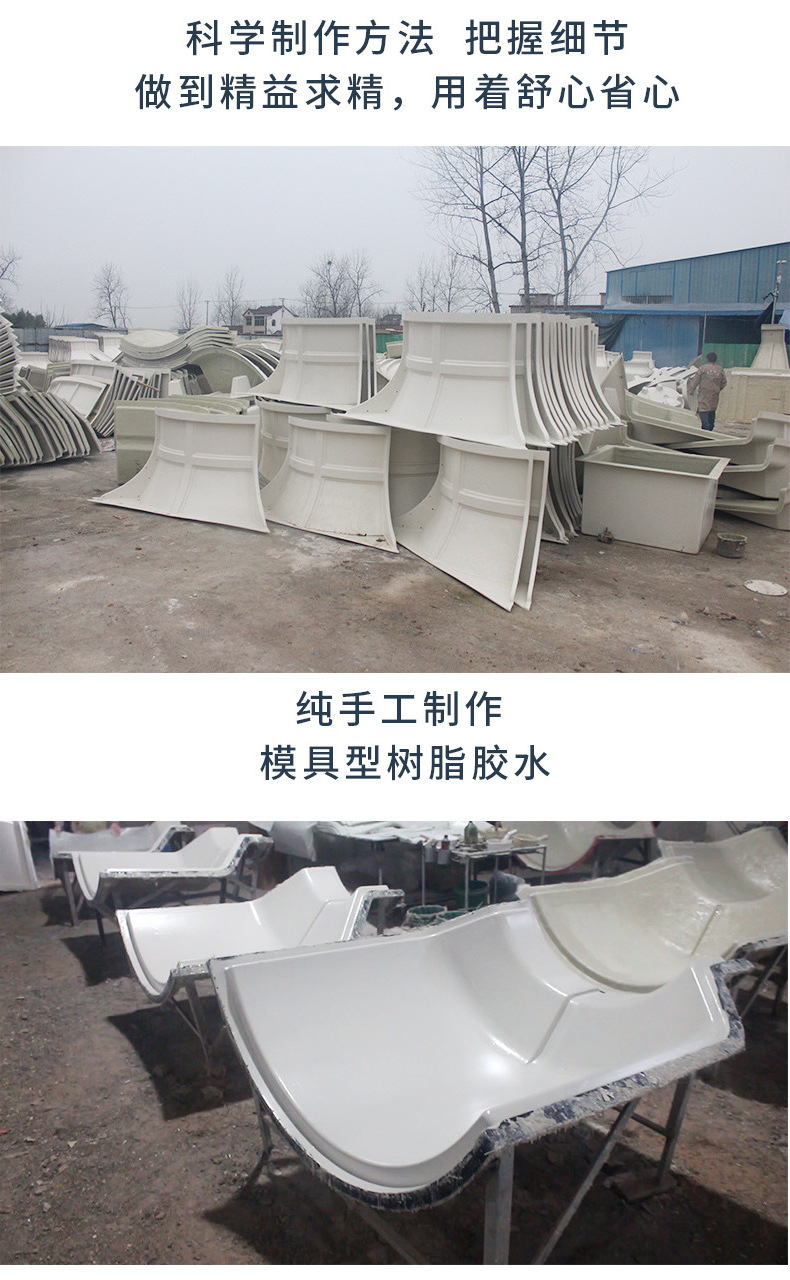

Material:

-

FRP

-

Voltage:

-

380V

-

Power:

-

11000

-

Place of Origin:

-

Zhejiang, China

-

Dimension(L*W*H):

-

2530mm*2230mm

-

Weight:

-

423 KG

-

Product name:

-

FRP GRP Cooling Tower

-

Type:

-

Counter Flow Closed Cooling Tower

-

Application:

-

Industrial Fluids Cooling

-

Shape:

-

Round.square

-

Usage:

-

Cooing Tower

-

After Warranty Service:

-

Video technical support, Online support

-

Local Service Location:

-

None

-

After-sales Service Provided:

-

Free spare parts

Products Description

FRP FACTORY WELCOME TO YOU.

FEATURE

1,Cooling tower is mainly used for cooling in air conditioning system, frozen series, injection molding, leather, foam, power

generation, steam turbine, aluminum processing, air compressors, industrial cooling water and other fields;

2,most used for air conditioning cooling, freezing, plastic chemical industry;

3, Closed circuit cooling tower have Attractive shape: Small dimension of shape, low height of tower, light weight of tower, and

multiform layout in covering area.

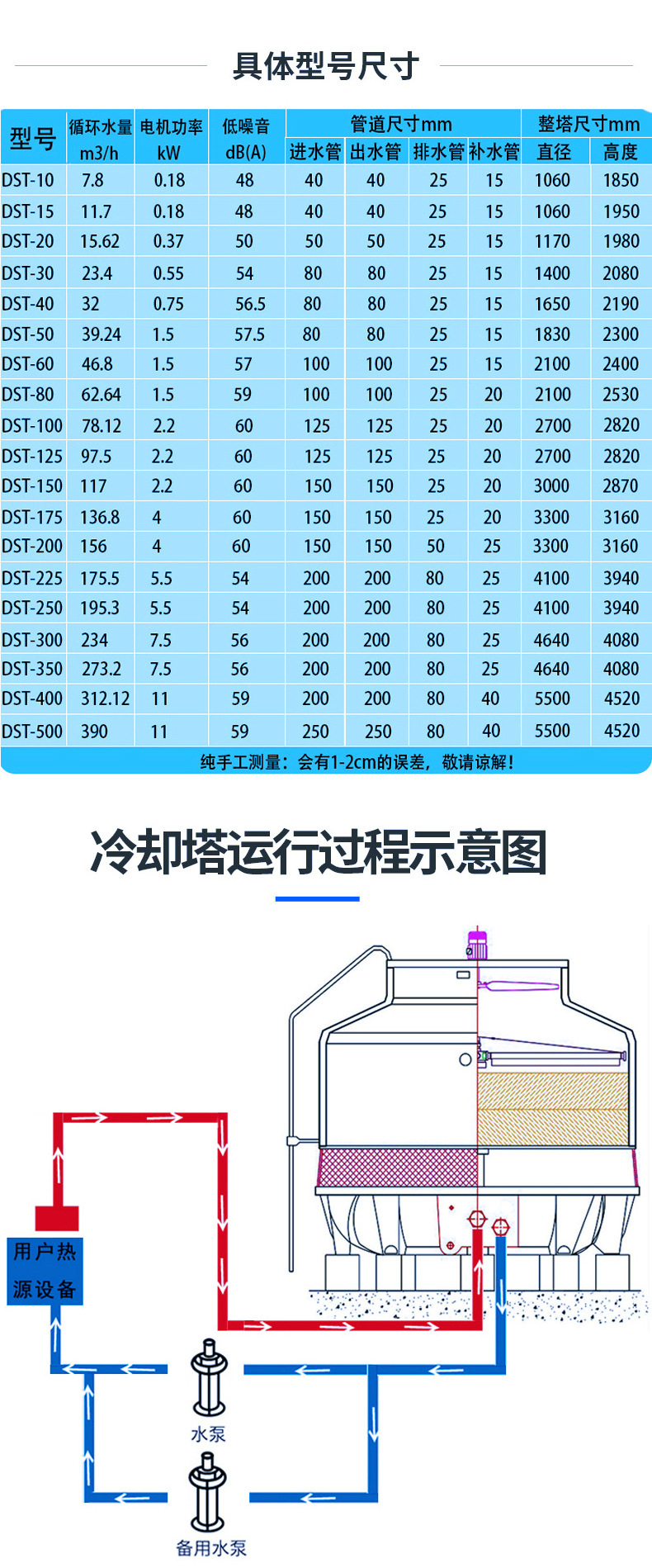

WORKING PRINCIPLE

1,Working fluid (water, oil o other liquid) flowing inside of the coils, which is enwrapped by spray water on the outside. The

heat of water is transferred by coil and become the saturated vapor when meet the water and air.

2, the heat is exhausted out of the tower by the tower by the top fan; water is collected back to the bottom tank and circulates

continuously. The spray water is cooled down via PVC radiation fin in the process of circulation, and flow is the same direction

with the fresh wind. The coil mainly takes sensible heat travel style.

3, the most benefit of this style is can avoid scale formation on the outside of the coil. And this will apply especially to

dealing with high temperature fluid (e.g. 60°C) or the fluid need big temperature difference (e.g. 60°C to 32°C).

1,Cooling tower is mainly used for cooling in air conditioning system, frozen series, injection molding, leather, foam, power

generation, steam turbine, aluminum processing, air compressors, industrial cooling water and other fields;

2,most used for air conditioning cooling, freezing, plastic chemical industry;

3, Closed circuit cooling tower have Attractive shape: Small dimension of shape, low height of tower, light weight of tower, and

multiform layout in covering area.

WORKING PRINCIPLE

1,Working fluid (water, oil o other liquid) flowing inside of the coils, which is enwrapped by spray water on the outside. The

heat of water is transferred by coil and become the saturated vapor when meet the water and air.

2, the heat is exhausted out of the tower by the tower by the top fan; water is collected back to the bottom tank and circulates

continuously. The spray water is cooled down via PVC radiation fin in the process of circulation, and flow is the same direction

with the fresh wind. The coil mainly takes sensible heat travel style.

3, the most benefit of this style is can avoid scale formation on the outside of the coil. And this will apply especially to

dealing with high temperature fluid (e.g. 60°C) or the fluid need big temperature difference (e.g. 60°C to 32°C).

Our Advantages

Recommend Products

Hot Searches