Name:Grizzly Hopper Feeder

Size (mm):2000*2000

Grizzly screen space:150mm or as required

Grizzly material:Railway tracks

Remark:Water spray pipes along hopper sides

Function:To feed the materials evenly to the scrubber and trommel

- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V/415V/440V / Customization, 380V/415V/440V / Customization

-

Dimension(L*W*H):

-

GTS600/800/1000/1200/1500/2000/2500

-

Weight:

-

5000 KG

-

Model:

-

GTS600/800/1000/1200/1500/2000/2500

-

Screening area:

-

4.71~44.90m2

-

Color:

-

Yellow, white, red, blue, gray( or as client request)

-

Application:

-

Food Processing, Alluvial gold washing, diamond, rock, soil

-

Installation:

-

Supply manual to guide user

-

Drum diameter:

-

800~2000mm

-

Driving Device:

-

Electric motor + Reducer

-

Slop angle:

-

Max.30°

-

Product name:

-

Heavy Duty River Sand Gold Trommel Screen Machine for Gold Mining

Quick Details

-

Production Capacity:

-

5-150 tons per hour

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Hengchang

-

Voltage:

-

380V/415V/440V / Customization, 380V/415V/440V / Customization

-

Dimension(L*W*H):

-

GTS600/800/1000/1200/1500/2000/2500

-

Weight:

-

5000 KG

-

Model:

-

GTS600/800/1000/1200/1500/2000/2500

-

Screening area:

-

4.71~44.90m2

-

Color:

-

Yellow, white, red, blue, gray( or as client request)

-

Application:

-

Food Processing, Alluvial gold washing, diamond, rock, soil

-

Installation:

-

Supply manual to guide user

-

Drum diameter:

-

800~2000mm

-

Driving Device:

-

Electric motor + Reducer

-

Slop angle:

-

Max.30°

-

Product name:

-

Heavy Duty River Sand Gold Trommel Screen Machine for Gold Mining

Products Description

Hot sale small scale gold mining equipment diamond lead zinc mine manganese zircon copper alluvial trommel wash machine plant

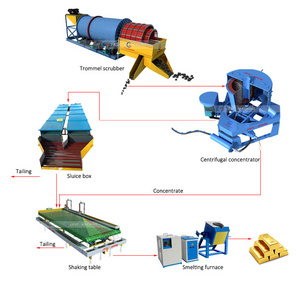

Mobile trommel screen is designed for alluvial/placer gold ore processing, it's consist of a half covered trommel screen, one diesel engine/ electric motor, water pump& water pipes, and other facilities such as the feeding hoper and the mobile system. This mobile trommel machine normally works together with sluice box , gold centrifugal concentrator and shaking table to form a complete ore concentration plant.

● It has been widely used for alluvial gold, placer gold, tantalite, niobite, and tin ore concentration.

● It is very popular in Africa, Asia, South America due to its easy to move and easy operation, low cost.

|

SPECIFICATION OF ALLUVIAL GOLD MINING MACHINE TROMMEL WASH PLANT

|

|

|

|

|||

|

Model

|

Hengchang - 50

|

Hengchang -150

|

Hengchang -400

|

|||

|

Size

|

7*2*3m

|

9.8*3*4m

|

15*3.5*5m

|

|||

|

Capacity

|

50-100 tph

|

150-250 tph

|

400-450 tph

|

|||

|

Power

|

24kw

|

75kw

|

200kw

|

|||

|

Feeder Hopper

|

2*2.2m

|

3.8*3m

|

6*4m

|

|||

|

Sluice box

|

1*2m (2pcs)

|

1*6m (3pcs)

|

1*6m (7pcs)

|

|||

|

Water power

|

7.5kw

|

45kw

|

150kw

|

|||

|

Clay Scrubber

|

1*2m

|

1.3*2.5m

|

2*2.5m

|

|||

|

Trommel Screen

|

1.2*3m

|

2*4m

|

2*7m

|

|||

|

Recovery Rate

|

98%

|

98%

|

98%

|

|||

Product Application

1.The quarry is used for classification of large and small stones and separation of soil and stone powder.

2.It is separated from sand and stone in sand and stone field.

3.The coal industry is used for the separation of lump coal and pulverized coal and coal washing (part of coal washing machine).

4.The chemical industry and mineral processing industry are used for the classification of large and small lumps and the separation of powdery substances.

3.The coal industry is used for the separation of lump coal and pulverized coal and coal washing (part of coal washing machine).

4.The chemical industry and mineral processing industry are used for the classification of large and small lumps and the separation of powdery substances.

Technical Details

Feeding System

Clay Processing System

Size (mm):φ1200*3000 or according to processing capacity

Remark:With inside water spray pipes

Function:To break off hard clays to increase gold recovery

Screening System

Name:Gold Trommel Screen

Size (mm):φ1500*3500 or according to processing capacity

Remark:2 layer trommel screen

Function:For washing, screening and separating the minerals

Water spray pipes:On both sides of the trommel

Mesh size:12mm and 6mm or according to clients requirement

Size (mm):φ1500*3500 or according to processing capacity

Remark:2 layer trommel screen

Function:For washing, screening and separating the minerals

Water spray pipes:On both sides of the trommel

Mesh size:12mm and 6mm or according to clients requirement

Coarse Gold Recovery System

Name:Vibrating Sluice + sluice box

Vibrating sluice type:Hydraulic type

Size:1m*6m

Sluice box carpet:Mitsubishi brand, imported from Japan

Function:For coarse gold recovery

Recovery rate: 99%

Vibrating sluice type:Hydraulic type

Size:1m*6m

Sluice box carpet:Mitsubishi brand, imported from Japan

Function:For coarse gold recovery

Recovery rate: 99%

Fine Size Gold Recovery System

Name:Knelson type centrifugal concentrator

Processing capacity:15tph-60tph dry solids

Quantity:2-4 pcs

Remark:Fully continuous type

Function:For fine size dust gold recovery (-6mm)

Recovery Rate:99%

Processing capacity:15tph-60tph dry solids

Quantity:2-4 pcs

Remark:Fully continuous type

Function:For fine size dust gold recovery (-6mm)

Recovery Rate:99%

Slurry pump

Quantity:1-3 pcs

Water flow:120-400m³ per hour

Function:For supplying water to the wash plant

Powering system

Power:100Kw-350Kw

Brand:Cummins, Weichai, or as required

Function:Supplying power to all the systems

Gold Shaker Table

Power:2.2Kw

Function:To further process the concentrates from the sluice and/or concentrators

Mercury Amalgamator

Type:V-shaped

Working mode:Amalgamator + distiller retort

Function:With the help of Mercury, to extract all the gold out from the concentrates that recovered by the sluice and concentrators.

Recovery rate:100%

Working mode:Amalgamator + distiller retort

Function:With the help of Mercury, to extract all the gold out from the concentrates that recovered by the sluice and concentrators.

Recovery rate:100%

Gold Smelting Furnace

Moulds:100g; 200g; 500g; 1000g

Function:To smelting the gold sand and make into final product of gold bars

Working Principle

Using excavator to feed raw material to the hopper ,then, they flow into double trommel , big stones and pebble can be separated and flow outside of the equipment, mineral aggregate with gold whose diameter is less than 6mm can enter into the beneficiation

sluice through inner trammel screen,there is a fixed and high extraction ratio gold felt sluice in one side of the beneficiation sluice to extract gold particle. The machine is equipped with big flow capacity and big head water pump, can supply high pressure

water for hopper, trammel, the mineral aggregate with gold will flow through the gold felt in the effect of self weight and waterpower ,lighter mud or sand will be washed away and big specific gravity gold is left on the gold felt.

sluice through inner trammel screen,there is a fixed and high extraction ratio gold felt sluice in one side of the beneficiation sluice to extract gold particle. The machine is equipped with big flow capacity and big head water pump, can supply high pressure

water for hopper, trammel, the mineral aggregate with gold will flow through the gold felt in the effect of self weight and waterpower ,lighter mud or sand will be washed away and big specific gravity gold is left on the gold felt.

Madagascar

Surinam

Nigeria

Hot Searches