- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

ALD

-

Dimension(L*W*H):

-

1200*1000*1150mm

-

Weight:

-

1-10t

-

Product name:

-

FRP GRP electrolytic tanks

-

Application:

-

lead electrolwinning Mining and metallurgy industry

-

Usage:

-

refining of zinc, nickle, cobalt

-

Compression strength:

-

70-100Mpa

-

Structure:

-

inner layer, middle polymer layer and outer layer

-

Dimension:

-

3000*1200*1400mm or customized

-

Features:

-

corrosion resist, long service life

-

Name:

-

polymer concrete cell

-

Standard:

-

ASTM C582

-

Design:

-

FEA software

-

Certification:

-

ISO9001

Quick Details

-

Capacity:

-

100-20000L

-

Max Working Pressure(MPa):

-

0 MPa

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

ALD

-

Dimension(L*W*H):

-

1200*1000*1150mm

-

Weight:

-

1-10t

-

Product name:

-

FRP GRP electrolytic tanks

-

Application:

-

lead electrolwinning Mining and metallurgy industry

-

Usage:

-

refining of zinc, nickle, cobalt

-

Compression strength:

-

70-100Mpa

-

Structure:

-

inner layer, middle polymer layer and outer layer

-

Dimension:

-

3000*1200*1400mm or customized

-

Features:

-

corrosion resist, long service life

-

Name:

-

polymer concrete cell

-

Standard:

-

ASTM C582

-

Design:

-

FEA software

-

Certification:

-

ISO9001

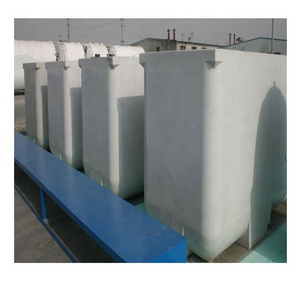

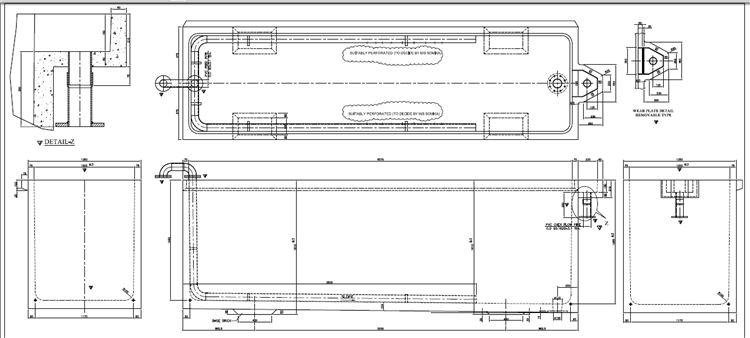

Polymer concrete cells for copper refining

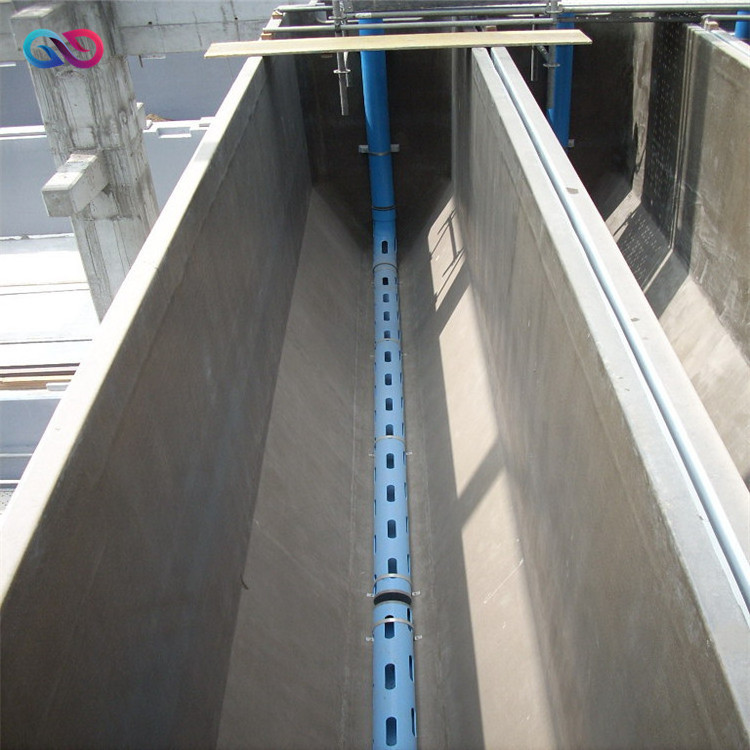

Electrolytic cell consists of three layers, the internal layer which contact with electrolytic solution and the external layer are FRP, middle layer is resin mortar. Materials be used are excellent corrosion-resist vinyl ester resin,high purity acid-resist quartz aggragates, glassfiber rebar and auxiliary agents, adopt monolithic casting process, no secondary lamination to internal layer, it makes electrolytic cells with high mechanical strength, excellent corrossion-resist and leakage-proof, technical defects of electrolytic cell with re-lining be resolved fundamentally.

Our monolithic casting electrolytic cells have high compression-resist, adopt advanced vibrating process, to guarantee it's compactness and strength. Internal layer is corrosion-resist FRP which can improve properties of corrosion-resist & leakage-proof and service life be extended. FRP rebar make cells with high strength, thin wall thickness, insulation and isolation, investment of tankhouse and auxiliary equipments be saved, and electrolytic efficiency be improved. We use monolithic steel molud manfacturing process and our exclusive hydraulic demoulding technology (patented), to improve production efficiency.

|

Property

|

Index

|

|

comperssion strength

|

70~100Mpa

|

|

flexural strength

|

22~27Mpa

|

|

shear strength

|

≥4.5Mpa

|

|

density (standdard hammered)

|

2150~2250kg/m³

|

|

volume resistance

|

≥3.4*1012 Ω•cm

|

|

dielectric strength

|

≥3.6KV/mm

|

|

thermal conductivity

|

≥1.2w/m•K

|

|

specific heat

|

≥800J/kg•K

|

|

thermal expansion coefficient

|

<20*10-5 m/m/℃

|

Electrolytic Cells:Innovations for Tankhouse Productivity

Electrolytic cell consists of three layers, the internal layer which contact with electrolytic solution and the external layer are FRP, middle layer is resin mortar. Materials be used are excellent corrosion-resist vinyl ester resin,high purity acid-resist quartz aggragates, glassfiber rebar and auxiliary agents, adopt monolithic casting process, no secondary lamination to internal layer, it makes electrolytic cells with high mechanical strength, excellent corrossion-resist and leakage-proof, technical defects of electrolytic cell with re-lining be resolved fundamentally.

Our monolithic casting electrolytic cells have high compression-resist, adopt advanced vibrating process, to guarantee it's compactness and strength. Internal layer is corrosion-resist FRP which can improve properties of corrosion-resist & leakage-proof and service life be extended. FRP rebar make cells with high strength, thin wall thickness, insulation and isolation, investment of tankhouse and auxiliary equipments be saved, and electrolytic efficiency be improved. We use monolithic steel molud manfacturing process and our exclusive hydraulic demoulding technology (patented), to improve production efficiency.

Electrolytic cells

Guaranteed Long-Term Impermeability,Free of Corrosion

Designed with a monolithic impermeable internal tank manufactured with multiple layers of fiber-reinforced premium vinylester resin.The specifications for this internal tank have been validated by proven impermeability and corrosion-free service for over 40 years in the chemical processing industries worldwide.

Manufacturer's 20 Year Warranty

Jiubo guarantees Electrolytic cells for continuous service without leaks, free of corrosion and structural flaws,operating under normal conditions as specified for each Project.

ViNYL ESTER RESIN INNER LINER

It's a monolithic tank made with multiple layers of fiber-reinforced vinylester resin (FRP) complying with chemical barrier that assure long-term impermeability and corrosion reistance.

Steel frame packaging for sea shipping

Deliver to seaport