- Product Details

- {{item.text}}

Quick Details

-

Knitting Method:

-

Single

-

Computerized:

-

Yes

-

Place of Origin:

-

Fujian, China

-

MODEL:

-

YFSG

-

DIA:

-

30"-42"

-

GAUGE:

-

16G-32G

-

FEEDERS:

-

3F-4F-6F/INCH

Quick Details

-

Type:

-

Circular

-

Production Capacity:

-

100%

-

Knitting Style:

-

Weft circular weaving loom

-

Knitting Method:

-

Single

-

Computerized:

-

Yes

-

Place of Origin:

-

Fujian, China

-

MODEL:

-

YFSG

-

DIA:

-

30"-42"

-

GAUGE:

-

16G-32G

-

FEEDERS:

-

3F-4F-6F/INCH

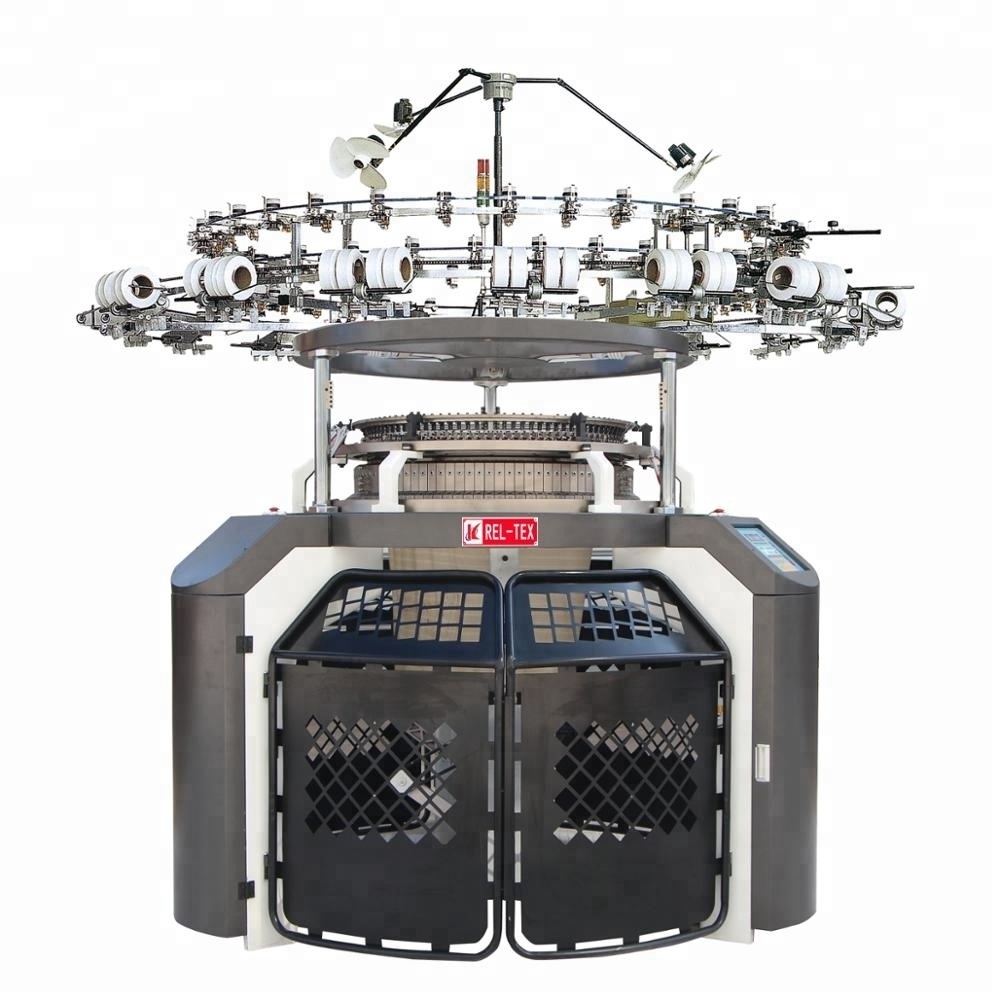

>>>>> High Speed Single Jersey Circular Knitting Machine

Single Jersey textiles always dominate the major trend in knitting industry.Single jersey circular knitting machine belongs to the circular knitting machine and possesses 4 tracks. Due to the cylinder 4-track cam design,it can produce various high-quality single jerseys with diverse patterns or thicknesses through different arrangement of cams and needles. Available single jerseys fabric include the pique fabric,mesh fabric,twill,polyester-cotton blended fabric,high elastic lycra fabric,plain weave fabric and fabric for swimwear. Our specially designed fabric rolling system enables cloth to be pulled evenly and reduces the probability of irregular color. It is applicable for processing materials like cotton yarn,blended yarn of various specifications,high-elastic polyester silk, chemical fiber and so forth

>>>>> Function and advantages

REL-TEX brand had introduced YFSG models with InterChangeable Conversion Kit and thereby facilitates the multi-function single jersey knitting tasks – Terry, Velour, Three-Thread Fleece - apply to REL-TEX versatile single jersey circular knitting machine.

1.Oil-Bathed Structure

The Oil-based frame prevents Gear Ring from rusting and further smoothes the performance of rotation.Its frame has undergone the natural aging treatment. The oil-immersed gear meshing drive model is praised for good stability and low noise..

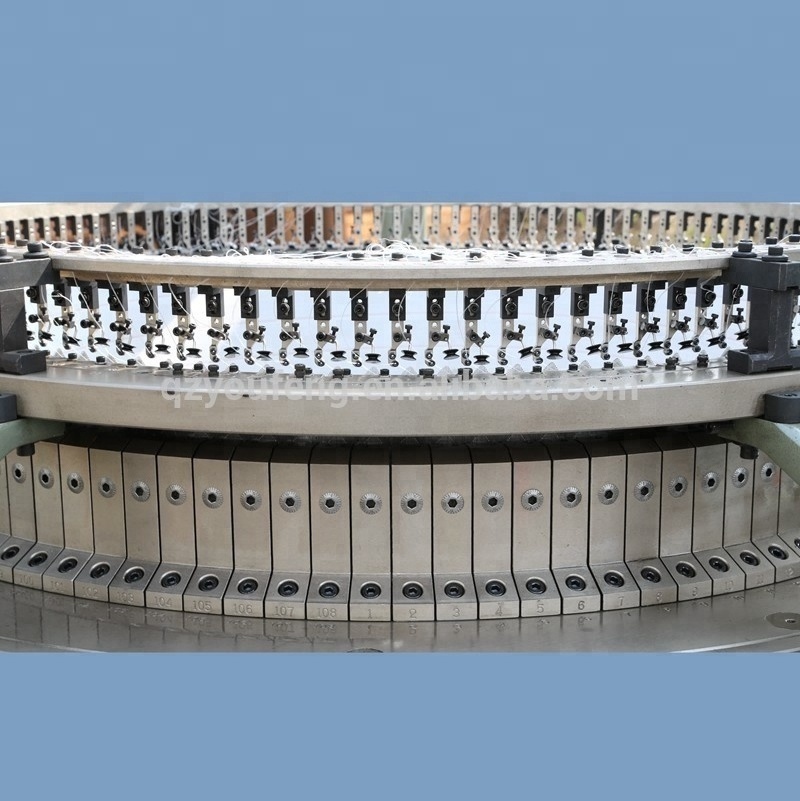

2.Concatenated Sinker Cam

New design of the doubled sinker-track guidances prolongs the service life of sinker. It will reduce friction between the sinker and the sinker cam, and avoid the defective striper on the fabric.

3.Advanced Computer Control System

Is able to automatically monitor and control all the operating parameters, such as spraying oil regularly in fixed quantity, dust removing, needle breakage detection, automatic stop when the fabric is broken, auto-stop when arriving the set output and so on

.

4.Fabric Rolling System

Is a special design, which easily rolls up the cloth and will not produce clear shadow. In addition, the machine is equipped with a safety stop device that will shut down the entire machine automatically once the problem occurs.

5. Low Power Consumption

Using German-made Steel Basing Track for the main plate driving gear, improves operating precision and pressure resistance, also substantially reduces the Power Consumption.

6.Dust exhausting fans

In the middle and at the top as well as bottom of the machine. They may effectively clear away accumulated cotton fiber, protect needles and sinkers, and enhance running efficiency.

7.Yarn Carrier

Tailor-made vertical yarn guide wheels prevent the needle from damage while applying Lycra/ Spandex and reduce the accumulation of extra cotton fiber.

8.Central Stitch Adjustment

Can be equipped on machine to adjust the fabric density and gram weight rapidly and precisely.

9. Long Machine Life

At least 15 years without problems.

>>>>> Machine Video Web From Youtube:

https://youtu.be/XBgX4pZWxpI

>>>>> Machine Specification

>>>>> Machine Pictures

Dail plate cams

Cylinder cams

Yarn carriers

Centeral stitch system

PIQUE

PLAIN

SPANDEX PLATING

SPANDEX PLATING

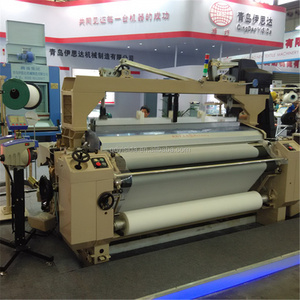

As an experienced Chinese manufacturer, HONGSHUO designs and assembles All Kinds of Circular Knitting Machine.

Our circular knitting machines may be categorized into the Single and Double Jersey Series,

Incorporated in 1996, our company is now located within the picturesque Luojiang District of Quanzhou city. We have imported advanced production equipment from countries such as Japan and Germany. At our disposal is the CNC vertical lathe, high-speed milling machine, CNC machining center, and other types of sophisticated machinery.Supported by sophisticated software such as CAD and CAM, we are now able to assemble up to 2000 machines each year. Through computerized rendering, we can fully analyze each component of our machines.

Years of development have allowed us to mature our design and production techniques. HONGSHUO has gradually risen to prominence as a trusted manufacturer in the domestic industry. Customers can rest assured, our dependable products come attached with excellent after-sales services. In the pursuit of excellence, we have placed a clear emphasis on quality and ingenuity The rapid growth and expansion of HONGSHUO is assisted by the contributions of a dedicated staff. Especially noteworthy is our technical taskforce, whom have greatly advanced our manufacturing proficiency for circular knitting machines. These professionals accurately analyze global fabric trends in order to provide customers with relevant products.

Development History

1996-Hongshuo Machinery Co.,Ltd. was founded in Quanzhou city, the starting point of Chinese maritime silk road.

1997-2004-Our company enjoyed a rapid development, gathered rich experience in the design and manufacture of knitting machines, and turned into a professional manufacturer.

2005-We imported 6 advanced CNC machine centers from Taiwan and edged ourselves into one of leading Chinese companies in the industry. Meanwhile, the construction of our new office building was underway.

2006-We started to attend professional textile machinery exhibitions at home and abroad annually.

2009-Our sales volume reached up to over 50 million yuan.

2010-Our products were famous for reliable quality and excellent after-sale service. With the innovation-based and quality-oriented business principle, now Hongshuo Machinery becomes a successful company who other knitting enterprises model themselves on.

2011-2012-We expanded our plant due to the rising sales volume.

2013-We have successfully developed new products, namely the high speed small double jersey seamless hosiery knitting machine and the small double jersey seamless hosiery jacquard knitting machine, which are well received by Langsha, a noted domestic enterprise specializing in pantyhose. Until May 2013, we sold nearly a thousand of these products, among which hundreds were purchases by Langsha.

2015-2017 - On the way to success,waiting for your joining!

HONGSHUO(REL-TEX) Machinery-trusted since 1996.

To learn more about our company,pls check our official website and watch our company introduction video :

www.rel-tex.com

Our quality - Product quality is our core competitiveness.We will carry out a through inspection of all the circular knitting machines and parts before delivery.so as to guarantee high product quality,if there is any quality problem under warranty,we will replace related parts for free.

Our after-sale service - We rely on our excellent after-sale service to keep long-term cooperative relationship with customers.If you require installing machine or solve technicial problems,We will immediately arrange technicians and provide you with satisfactory service.

Characteristics and application of our products - Our circular knitting machines are all controlled by microcomputers,which facilities operation and improves safety.The new-type 120 series cloth-rolling machines are applied,due to high stability,they can adjust the crimp and tension according to diverse fabrics,guarantee uniform density of colth,and prevent flaws like marks.We adopt the needles of Groz-Beckert and sinkers of Kern-Liebers.In addition,every parts,including the motor,inverter.oliler,yarn storage device and yarn creel,is selected rigorous,so as to enhance product quality.Since all these parts have undergone electroplating,polishing and baking finish by dedicated paint,our machines look lustrous and enjoy long working life.

Our technical advantage - Our machines are proud of high precision,good quality,large output and fast revolving speed,They implement the central stitch system,and are easy to use.The motors contributes to energy saving.