- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380v

-

Weight:

-

200 KG

-

Marketing Type:

-

Hot Product 2024

-

Product name:

-

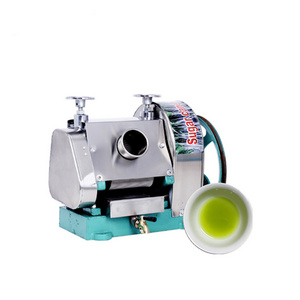

Fruit Juicer Extractor Machine

-

Usage:

-

Juicer Extrator

-

Material:

-

304 Stainless Steel

-

Application:

-

Beverage Fruit Store

-

Feature:

-

Big Mouth Feeding

-

Capacity:

-

500kg/h

-

Suitable for:

-

Fruit Processing Industry

-

Output:

-

0.5T/H 1T/H

-

PACKING:

-

Customized Packing

-

MOQ:

-

1 Set

Quick Details

-

Place of Origin:

-

China

-

Brand Name:

-

runxiang

-

Power:

-

9kw

-

Voltage:

-

380v

-

Weight:

-

200 KG

-

Marketing Type:

-

Hot Product 2024

-

Product name:

-

Fruit Juicer Extractor Machine

-

Usage:

-

Juicer Extrator

-

Material:

-

304 Stainless Steel

-

Application:

-

Beverage Fruit Store

-

Feature:

-

Big Mouth Feeding

-

Capacity:

-

500kg/h

-

Suitable for:

-

Fruit Processing Industry

-

Output:

-

0.5T/H 1T/H

-

PACKING:

-

Customized Packing

-

MOQ:

-

1 Set

Product Description

1.Used for pressing pineapple, apple, pear and other fruits;

2.It is used for pressing mulberries, grapes, oranges, and other berries.

3.It is used for pressing tomatoes, ginger, garlic, celery and other vegetables.

4.Screw push extrusion;

5.Fully automatic juicing and slag removal of berries, kernels and vegetables;

6.The contact part with materials is made of national standard 304 stainless steel.

7.The rack material can be made of national standard 304 stainless steel.

Feature

1.The main part which contact the fruits is made of stainless steel which is very health and safe.

2.It is also the ideal crusher equipment for food process company ,beverage process company ,hotel and restaurant private business company.

3.It uses globally proven technology with excellent product quality, it can well meet our low investment ,high yield goal.

4.It is easy to clean and maintain and operate.

2.It is also the ideal crusher equipment for food process company ,beverage process company ,hotel and restaurant private business company.

3.It uses globally proven technology with excellent product quality, it can well meet our low investment ,high yield goal.

4.It is easy to clean and maintain and operate.

Technology

We will test before shipping,to confirm customers receivedt he good quality machine.

Raw material

SS304

Size Information

|

Model

parameter |

RX-500

|

RX-1000

|

RX-1500

|

RX-3000

|

|

|

Raw material handling capacity

|

500Kg/hour

|

1000Kg/hour

|

1500Kg/hour

|

2T-3T/hour

|

|

|

Spiral diameter

|

Φ87.5mm

|

Φ120mm

|

Φ175mm

|

Φ205mm

|

|

|

Filter pore size

|

0.6mm

|

0.6mm

|

0.6mm

|

0.6mm

|

|

|

Motor Power

|

1.5Kw

|

2.2KW

|

4Kw

|

4Kw

|

|

|

Spindle speed

|

400rpm

|

400rpm

|

|

400rpm

|

|

|

Weight

|

~105Kg

|

175KG

|

~250Kg

|

500kg

|

|

|

Size

|

909×320×833mm

|

1250x500x1100mm

|

1600×500×1350mm

|

2050*760*1580mm

|

|

|

Inlet size

|

0.25m*0.25m

|

0.35*0.35m

|

0.4m*0.45m

|

0.4m*0.45m

|

|

Detailed Images

Suitable for cutting fruits Suitable for whole fruits

Like: apples,

Oranges, lemons, tangerines, pineapples, limes, pomelos, grapefruit.

But need cutting it in piece by piece ADVANCE!!!!

Like: apples,Oranges, lemons, tangerines, pineapples, limes, pomelos, grapefruit.

Machine can cut the fruit !Not need cutting advance !!

Working Principle

The main component of this equipment is that the bottom diameter of the spiral gradually increases and the pitch gradually decreases along the direction of the slag outlet. When

the material is pushed by the spiral, the volume of the spiral cavity is reduced, resulting in squeezing of the material.

The rotation direction of the spiral spindle is clockwise when viewed from the feed hopper to the slag trough.

The raw materials are added to the feeding hopper and are pressed by the advancement of the screw. The squeezed juice flows into the juice container at the bottom through the filter, while the waste materials are discharged through the annular gap formed between the screw and the pressure-regulating conical part. The axial movement of the pressure regulating head can adjust the size of the gap.

It is used clockwise (when turning the handwheel shaft when looking at the bearing seat from the slag discharging trough of the equipment to the feeding hopper end, the pressure regulating head is to the left, the gap will be reduced, and vice versa, the gap will be enlarged.) To change the size of the gap, that is, adjust the discharge Slag resistance. You can change the slag extraction rate, but if the gap is too small, some of the slag particles will be squeezed out through the filter together with the juice under strong squeezing. Although the juice output increases, the quality of the juice will decrease relatively.

The raw materials are added to the feeding hopper and are pressed by the advancement of the screw. The squeezed juice flows into the juice container at the bottom through the filter, while the waste materials are discharged through the annular gap formed between the screw and the pressure-regulating conical part. The axial movement of the pressure regulating head can adjust the size of the gap.

It is used clockwise (when turning the handwheel shaft when looking at the bearing seat from the slag discharging trough of the equipment to the feeding hopper end, the pressure regulating head is to the left, the gap will be reduced, and vice versa, the gap will be enlarged.) To change the size of the gap, that is, adjust the discharge Slag resistance. You can change the slag extraction rate, but if the gap is too small, some of the slag particles will be squeezed out through the filter together with the juice under strong squeezing. Although the juice output increases, the quality of the juice will decrease relatively.

The size of the gap should be considered It depends on the specific process requirements of the user.

Factory and Shipping

Hot Searches