- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380v

-

Dimension(L*W*H):

-

3400 1880 2550

-

Power (kW):

-

22

-

Weight (KG):

-

1800 KG

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

MEISU

-

Machine Type:

-

EPS, PS

-

Voltage:

-

380v

-

Dimension(L*W*H):

-

3400 1880 2550

-

Power (kW):

-

22

-

Weight (KG):

-

1800 KG

Product Description

EPS Hot Melting Machine

The EPS foam hot melt compressor compresses foam by means of screw heating and melt extrusion, and then scrapes foam into EPS foam compression block. Our foam hot-melt compressor can reduce the waste volume by 80% -90%, greatly reducing the storage and transportation costs of EPS foam. It is a good choice for EPS foam recycling.

The hot-melt machine, also known as foam EPS recycling machine, can crush waste foam plastic materials into small pieces with blades and screws, and then easily compress them into compact foam ingots. After compaction, the waste foamed plastic can be reused to manufacture other products, such as frame products and building molded products.

Working princinple

The EPS hot melt machine uses a dual axis crusher, which can effectively crush the foamed polystyrene material into smaller blocks and enter the sieve. The materials that cannot enter the screen are crushed again, fall into the screen, and then enter the main machine. The high-speed rotation of the screw transports the crushed materials to the conical and circular cylinder bodies. The materials are heated and melted by the cloud ceramic heater, and the recycled objects are extruded from the mouth mold. According to the required size, the production process is completed by the automatic cutting of the cutting machine.

Products Features

Products Features

1. The feeding port has a moderate height, making it convenient for feeding and ensuring safety.

2. It can handle different kinds of foaming materials, such as foam boxes, foam boards, etc.

3. Use low noise mufflers.

4. It adopts detachable blades, which can be disassembled separately and sharpened after being blunt.

5. Suitable for crushing various soft, hard, and foamed plastics.

6. Simple operation and high output

Technical Parameters

|

model

|

MSH-50

|

MSH-100

|

MSH-200

|

|

Screw diameter

|

ф138mm

|

ф197 mm

|

φ250 mm

|

|

Screw length

|

1090mm

|

—

|

180 mm

|

|

Screw speed

|

165rpm

|

130 r/min

|

160 r/min

|

|

Size of feed inlet

|

650mmx400mm

|

—

|

—

|

|

Extrusion center height

|

250mm

|

326 mm

|

366 mm

|

|

Heating power

|

Divided into two zones, each zone is 3kw

|

3 zones total 10kw

|

Total 14KW in three zones

|

|

Main motor power

|

5.5kw

|

15KW

|

22KW

|

|

Filter aperture

|

40mm

|

40mm

|

50 mm

|

|

Blade rotation diameter

|

250mm

|

—

|

—

|

|

Number of blades

|

12 pieces

|

Double axis 11+10

|

Four axis 11+10+11+10

|

|

Knife shaft speed

|

150rpm

|

100r/m

|

100r/m

|

|

Machine dimensions

|

1200x1000x1400

|

2800x1580x1950

|

3400x1880x2550

|

|

Weight

|

800kg

|

1400 Kg

|

1800 Kg

|

|

Yield

|

50kg/h

|

100~120Kg/h

|

200Kg/h

|

|

Crusher power

|

—

|

2.2kwx2

|

2.2kwx4

|

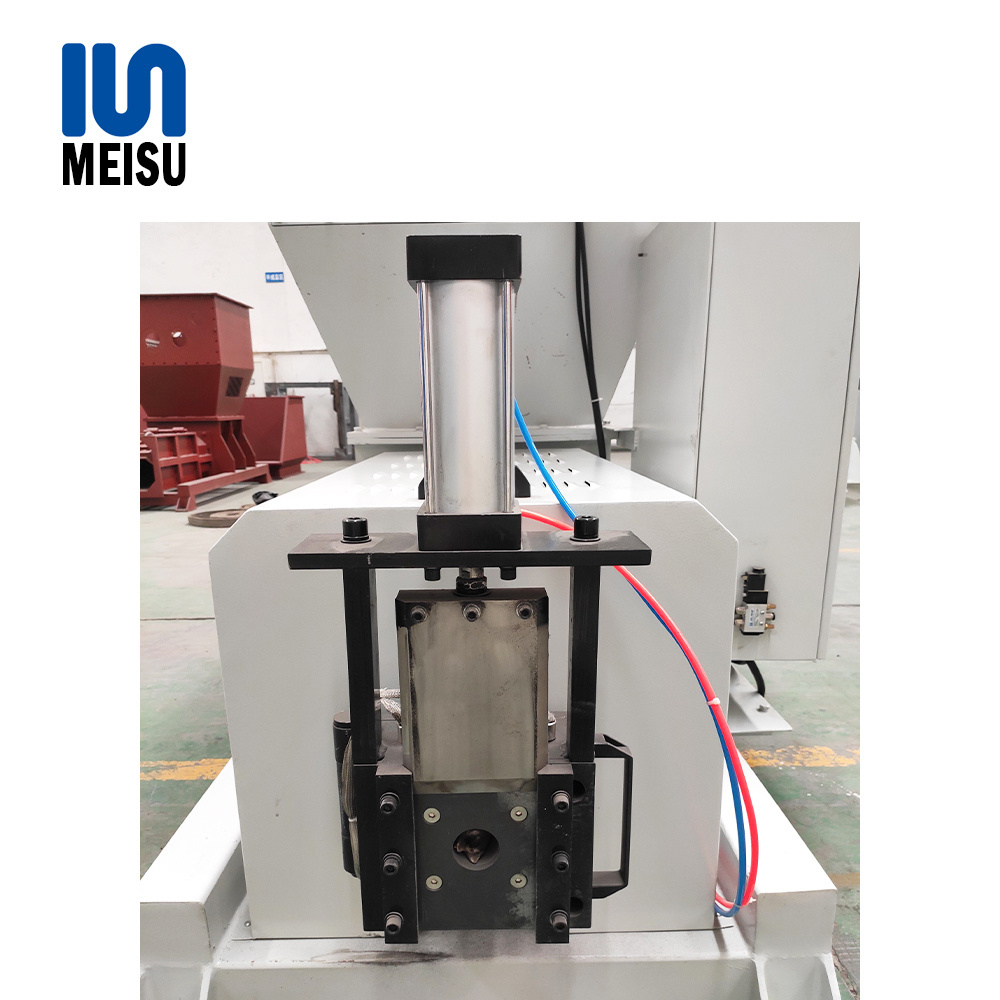

Detail photos

Apllication

Suitable Products:

It is mainly suitable for recycling processing centers, which can process foaming materials such as EPS, EPE, EPP (with optional frequency converter), and can reduce waste volume by 80% -90%.

Hot Searches