- Product Details

- {{item.text}}

Quick Details

-

Machinery Capacity:

-

40-60, 80-100

-

Machinery Function:

-

bone crushing, bone grinding

-

Product name:

-

automatic bone meal machine/bone crusher/beef bone milling machine

-

Application:

-

cow chicken pig Bone etc crushing

-

Advantage:

-

Easy Operation High Efficiency

-

Color:

-

Stainless Steel Color

-

Certification:

-

CE

-

Packing:

-

Wooden Case Packing

-

Material:

-

Stainless Steel 304/316L

-

Feature:

-

High Efficiency Easy Operation

-

Spare Parts:

-

Two Knives

-

Energy:

-

Electic

Quick Details

-

Weight (KG):

-

160

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Ainuok

-

Machinery Capacity:

-

40-60, 80-100

-

Machinery Function:

-

bone crushing, bone grinding

-

Product name:

-

automatic bone meal machine/bone crusher/beef bone milling machine

-

Application:

-

cow chicken pig Bone etc crushing

-

Advantage:

-

Easy Operation High Efficiency

-

Color:

-

Stainless Steel Color

-

Certification:

-

CE

-

Packing:

-

Wooden Case Packing

-

Material:

-

Stainless Steel 304/316L

-

Feature:

-

High Efficiency Easy Operation

-

Spare Parts:

-

Two Knives

-

Energy:

-

Electic

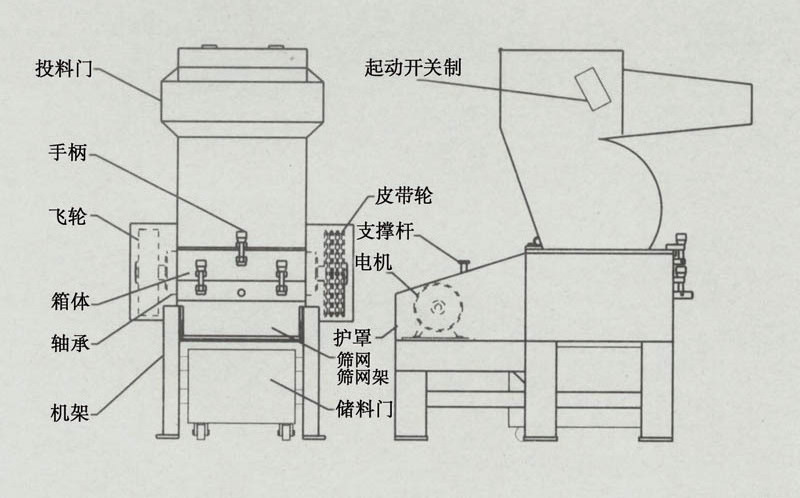

Stainless automatic bone crusher mill/animal bone crusher cow bone grinding grinder machine

Product Description

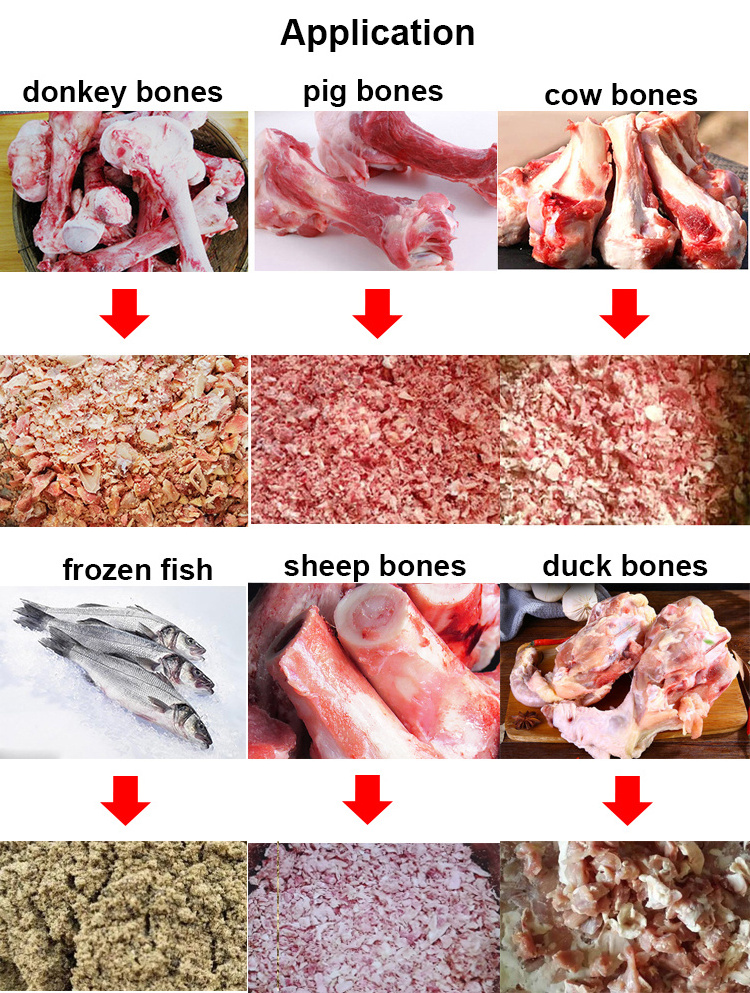

Stainless automatic bone crusher mill/animal bone crusher cow bone grinding grinder machine

is made of

stainless steel

and has a f

ood hygiene level

. It can crush

bone

and

meat materials

such as c

attle bone , sheep bone, pig bone, rabbit bone, duck bone,

and froze

fish etc.

This machine is

widely used

in various

sausages

,

ham

sausages,

luncheon

meats,

meatballs

,

quick-frozen

foods, salty flavors,

bone marrow

extraction, bone

meal

, bone

mineral

, bone

broth,

bone

peptide

extraction,

biological

products, convenient fabric packages, composite seasonings, crushing of hard materials

such as

catering ingredients, pet food and frozen meat.

Product Advantages

1.

Double-layer

sound insulation of the

fuselage

,

thickened plates

on both sides

2.

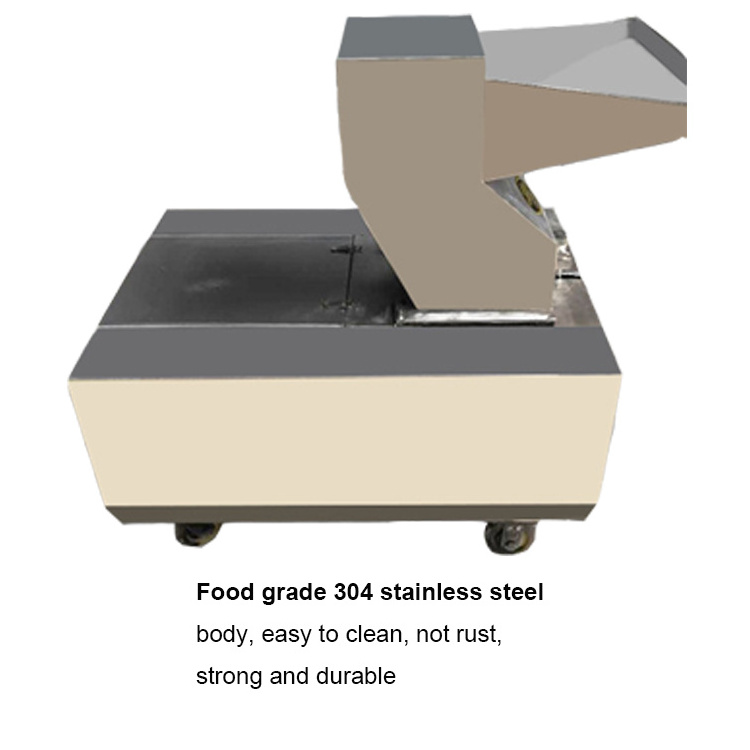

SUS304

stainless steel

body,

in line with

food safety standards

, clean and hygienic

3.

Simple disassembly

and

assembly

,

convenient cleaning

and

maintenance

4.

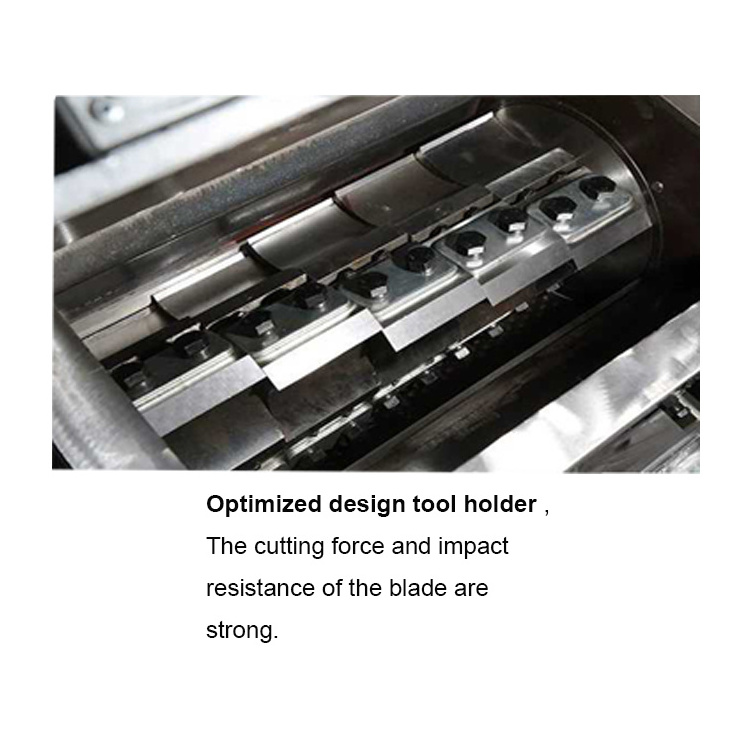

SKD-11 blade

, high hardness, high temperature resistance, sharp and durable

5.

Pure copper motor

, more powerful, equipped with overload protection and reverse rotation device, and power supply chain protection to ensure the safety of operators

6. The

knives

are

easy to install

, can be adjusted telescopically, and can be

removed

and

sharpened

repeatedly after being blunt.

7. The

operation control panel

is clear,

simple

and

easy to understand

, and quickly learn how to use it

8.

Wide feed inlet

, no residue left

9.

Optimized design

of the

tool holder

, the tool disperses the force, which improves the shear force and impact resistance of a single blade

10. The

front blade

increases the cutting angle of the blade, improves the cutting efficiency, and crushes the particles evenly.

11. The

size of the screen aperture

can be

customized

to meet the needs of different discharge sizes

12.

Enlarge

and

lengthen

the

receiving drawer

to store more materials and make it easier to pick up materials

13.

Material baffle design

to prevent material splashing

14. Equipped with

universal wheels

, easy to move

15. A

variety of blade numbers

to choose from:

2-7

blades

16. The

cutting tool

is made of

3Cr13

special plate, and after vacuum heat treatment, the

hardness

of the blade reaches

50 deg

rees.

Enquire

Us and

Get

the Following

Gifts

Freely:

1. 2021 Full

Catalogue

2. 2021 Full Price

List

3. Technical

Brochure

4. Operation

Manual

5. A Surprising

Discount

6. Some

Free

Accessories

Specification

|

Model

|

Capacity

|

Power

|

Weight

|

Inlet diameter

|

Dimension

|

|

PG-180

|

40-60KG/H

|

3KW

|

160KG

|

180*165MM

|

450*720*900MM

|

|

PG-300

|

80-200KG/H

|

5.5KW

|

330KG

|

310*230MM

|

1080*740*1160MM

|

|

PG-500

|

200-600KG/H

|

11KW

|

750KG

|

520*350MM

|

1450*980*1380MM

|

|

PG-600

|

700-900KG/H

|

22KW

|

1200KG

|

600*320MM

|

1700*1480*1760MM

|

|

PG-700

|

1000-1500KG/H

|

37KW

|

1800KG

|

700*480mm

|

2000*1600*2000MM

|

|

PG-800

|

800-2200KG/H

|

55KW

|

2200KG

|

800*650MM

|

1600*2100*2620MM

|

Packing & Delivery

1. 5 layers of plastic film wrapped around the body to prevent moisture and rain during transportation

2. Export thick wooden box, 5-15 cm thick, to ensure the safety of the machine during transportation

3. Trucks and centralized boxes directly transport the machines from the factory to the port for loading

2. Export thick wooden box, 5-15 cm thick, to ensure the safety of the machine during transportation

3. Trucks and centralized boxes directly transport the machines from the factory to the port for loading

Establish cooperation with dozens of logistics companies,goods can be transported by sea,rail and air,to ensure timely delivery to customers.

Support TT,Apple Pay,Google Pay,PayPal,Western Union and other payment methods

Support TT,Apple Pay,Google Pay,PayPal,Western Union and other payment methods

Enquire

Us and

Get

the Following Gifts Freely:

1. 2021 Full

Catalogue

2. 2021 Full Price

List

3. Technical

Brochure

4. Operation

Manual

5. A Surprising

Discount

6. Some

Free

Accessories

Hot Searches