- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220V/380V/415V/440V

-

Power:

-

7.5KW

-

Dimension(L*W*H):

-

3000*1200*2200mm

-

Weight (KG):

-

1890

-

Product name:

-

Single Arm Foundry Resin Sand Mixer

-

Capacity:

-

5-50 T/h

-

Application:

-

Foundry Industry

-

Technology:

-

Resin Sand Technology

-

Foundry Machine:

-

Single Arm Sand Mixer Machine

-

Usage:

-

Resin sand mixing

-

Casting plant:

-

Foundry Sand Moulding Line

-

After-sales Service Provided:

-

Free spare parts

Quick Details

-

Place of Origin:

-

Shandong, China

-

Machine Type:

-

Sand treatment casting equipment

-

Brand Name:

-

TZZJ

-

Voltage:

-

220V/380V/415V/440V

-

Power:

-

7.5KW

-

Dimension(L*W*H):

-

3000*1200*2200mm

-

Weight (KG):

-

1890

-

Product name:

-

Single Arm Foundry Resin Sand Mixer

-

Capacity:

-

5-50 T/h

-

Application:

-

Foundry Industry

-

Technology:

-

Resin Sand Technology

-

Foundry Machine:

-

Single Arm Sand Mixer Machine

-

Usage:

-

Resin sand mixing

-

Casting plant:

-

Foundry Sand Moulding Line

-

After-sales Service Provided:

-

Free spare parts

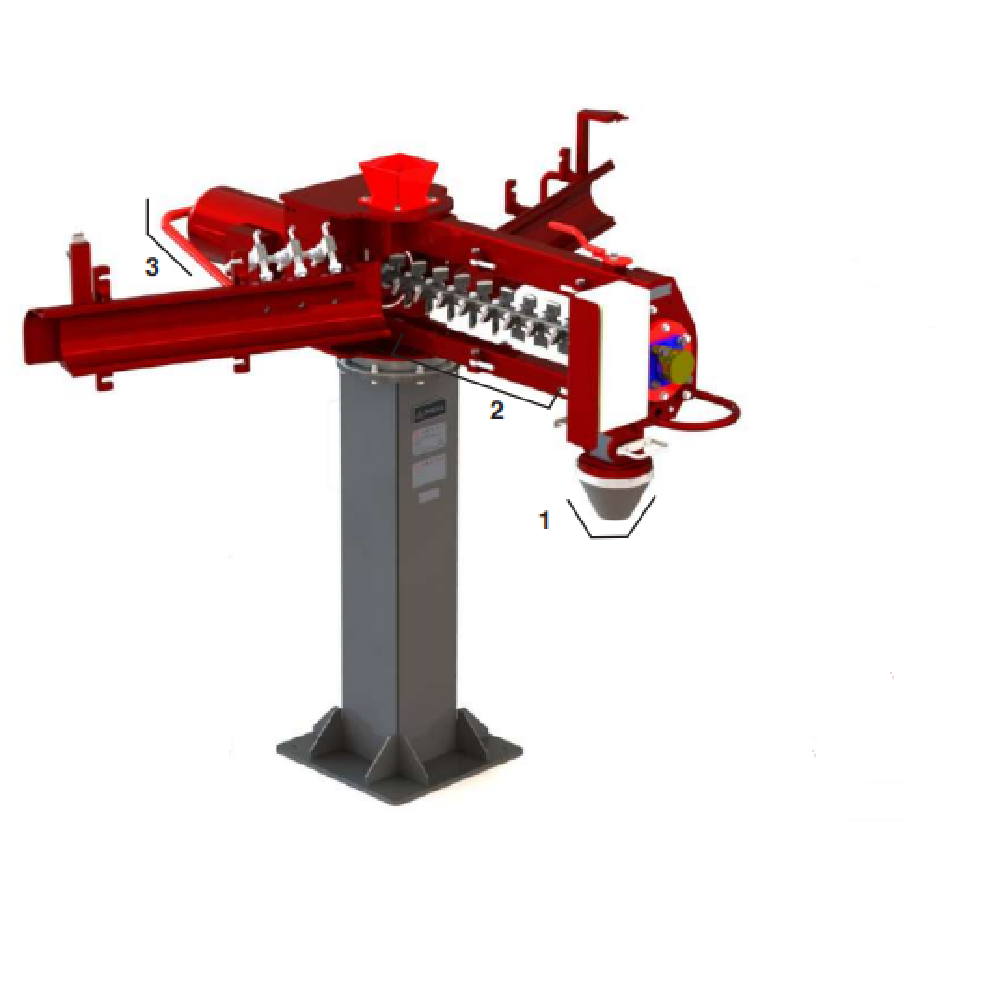

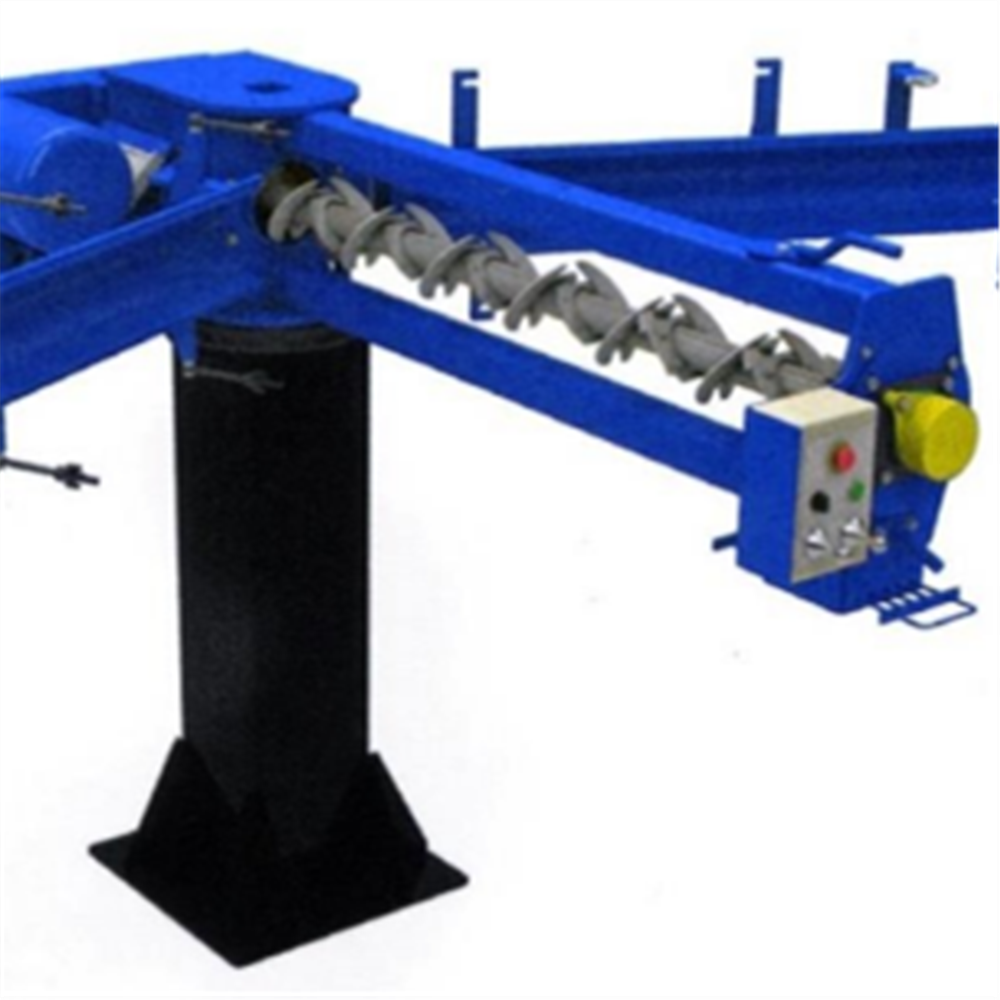

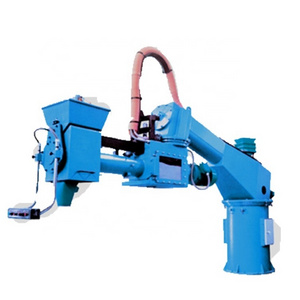

Single-arm resin sand mixer

Single-arm resin sand mixer, resin sand mixer is suitable for the mixing of various kinds of self-hardening sand such as resin sand, water glass sand, etc. in the production of cast steel, cast iron, non-ferrous alloys, etc. The requirements of manual modeling can also be configured for use in HR core shooter, mechanized modeling and core production.

Resin sand mixing foundry equipment, a continuous operation of the core sand sand mixing machine, the machine is made of continuous mixing liquid curing agent and liquid resin or self-hardening sand core making use of resin sand mixer. Resin sand sand mixer can be divided into: single arm resin sand mixer and double arms resin sand mixer .

the single arm sand mixer agglomerant system adopt electric variable diaphragm pump,light weight,compact size,the flow is stable and reliable. sand mixed system of uniform,effectively ensure the shape(core systm) quality. sand mix short time,without a head,tail sand,down the back of clean material.wide-open cage-type wal of sand up for leaf clean-up or adjustment,to facilitate the operation and maintenance.

the single arm sand mixer agglomerant system adopt electric variable diaphragm pump,light weight,compact size,the flow is stable and reliable. sand mixed system of uniform,effectively ensure the shape(core systm) quality. sand mix short time,without a head,tail sand,down the back of clean material.wide-open cage-type wal of sand up for leaf clean-up or adjustment,to facilitate the operation and maintenance.

|

Model

|

S242

|

S243

|

S245

|

S248

|

|||

|

Productivity (t/h)

|

2

|

3

|

5

|

8

|

|||

|

Diameter (mm)

|

Φ175

|

Φ175

|

Φ203

|

Φ219

|

|||

|

Rotation rate (r/min)

|

940

|

960

|

960

|

960

|

|||

|

Motor power (kw)

|

2.2

|

3

|

4

|

5.5

|

|||

|

Gyration radius (mm)

|

R850

|

R1500

|

R2000

|

R2000

|

|||

|

Curing agent for pump flow (l/h)

|

49

|

49

|

49

|

75

|

|||

|

Binder quantitative accuracy

|

<±2%

|

|

|

|

|||

Product Description

Features:

1. The molding sand in the machine is completely drained after the machine is stopped to avoid cleaning difficulties caused by the molding sand hardening.

2. Electricity adopts imported plc control, stable and reliable work, and automatic production.

3. The spindle speed is set to medium speed and the blades are distributed uniquely, making the sand mixing more uniform.

4. The sand-mixing blade is made of tungsten steel cemented carbide with standard steel casting, which is super wear-resistant.

5. The stirring cage adopts a horizontal split structure, which is convenient for cleaning or adjusting the sand mixing blades, and is easy to operate and maintain.

6. Special adhesive feeding system and molding sand discharge port design, with precise control, the sand mixer can realize basically no head and tail sand loss during starting and stopping.

7. Resin is conveyed by gear pump (with stepless speed governor), and curing agent conveying pump is mechanical diaphragm pump imported from Italy.

8, industry terms: resin sand mixer, resin sand mixer, single-arm sand mixer, resin sand equipment

1. The molding sand in the machine is completely drained after the machine is stopped to avoid cleaning difficulties caused by the molding sand hardening.

2. Electricity adopts imported plc control, stable and reliable work, and automatic production.

3. The spindle speed is set to medium speed and the blades are distributed uniquely, making the sand mixing more uniform.

4. The sand-mixing blade is made of tungsten steel cemented carbide with standard steel casting, which is super wear-resistant.

5. The stirring cage adopts a horizontal split structure, which is convenient for cleaning or adjusting the sand mixing blades, and is easy to operate and maintain.

6. Special adhesive feeding system and molding sand discharge port design, with precise control, the sand mixer can realize basically no head and tail sand loss during starting and stopping.

7. Resin is conveyed by gear pump (with stepless speed governor), and curing agent conveying pump is mechanical diaphragm pump imported from Italy.

8, industry terms: resin sand mixer, resin sand mixer, single-arm sand mixer, resin sand equipment

Facade

B

ackside

Detailed Images

Company Introduction

Qingdao Tianzhuang casting Machine Industry and Trade Co., Ltd is a professional manufacturer of foundry machinery, composed of engineering and technical personnel engaged in the foundry machinery industry for many years. Our company can undertake design,casting, installation, commissioning and other turn-key projects of clay sand, resin sand, water glass sand, lost foam and V method production line machinery and chemical department, as well as various stand-alone and spare parts business.

The company adhering to the concept of 'quality first, customer first', and create brilliant together with colleagues in the

casting industry.

The company adhering to the concept of 'quality first, customer first', and create brilliant together with colleagues in the

casting industry.

Our Services & Strength

1. Before payment

a. Free contact for the most suitable machine.

b. Free professional design for each customer especially.

c.Welcome to visit our factory.

2. After-Sales Service We will send engineers / technicians to make commissioning at buyer’s factory, train the machine works well, and also supply the technical support for free and spare parts at good price always.

3.Guarantee Period One year. During the guarantee period, the seller guarantee to solve all problems may occur due to machine's quality or wrong design, and to provide all necessary spare parts for repair, Seller can send the technician to buyer's factory on seller's account if problem is serious and can't be solved by Buyer.

4. Payment Terms 30% as deposit, 70% after the machine is ready before delivery.

5. Lead Time Our delivery time generally it is 10-30 days if the machines are in stock, or it is 20-45 days if the machines are not in stock, it is according to quantity.

1. Plastic film packaging and put in plywood wooden cases or according to customer's requirements.

2. Shipping: Container transport

FAQ

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to

quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 30% T/T in advance ,balance before shippment.

If you have another question, pls feel free to contact us as below:

After-sale Service Road Surface Shot Blasting Machine

1. Installation and commissioning issue

We will send 1-3 technicians to assist with machine installation and commissioning,

customer pays for their tickets, hotel and diet, etc Customer need arrange

3-4 skilled worker and prepare insallation machinery and tools.

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to

quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 30% T/T in advance ,balance before shippment.

If you have another question, pls feel free to contact us as below:

After-sale Service Road Surface Shot Blasting Machine

1. Installation and commissioning issue

We will send 1-3 technicians to assist with machine installation and commissioning,

customer pays for their tickets, hotel and diet, etc Customer need arrange

3-4 skilled worker and prepare insallation machinery and tools.

Hot Searches