- Product Details

- {{item.text}}

Quick Details

-

Knitting Method:

-

Single

-

Computerized:

-

Yes

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

PYZZ

-

Model Number:

-

MS18-B

-

Power:

-

7.5kw

-

Weight:

-

3.5 tons

-

Dimension(L*W*H):

-

2100*2300*3400

-

Application:

-

fake fur, wollen fabric

-

Certificate:

-

CE ISO

-

Function:

-

sliver knitting

-

Needles:

-

91.75/88.82

-

Gauge:

-

14g

-

needle Nos:

-

1184

-

Main power:

-

7.5kw

-

Cylinder:

-

27"

-

Feeder:

-

18F

-

Software:

-

Pattern design system

Quick Details

-

Type:

-

Circular

-

Production Capacity:

-

HIGH

-

Knitting Style:

-

FUR

-

Knitting Method:

-

Single

-

Computerized:

-

Yes

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

PYZZ

-

Model Number:

-

MS18-B

-

Power:

-

7.5kw

-

Weight:

-

3.5 tons

-

Dimension(L*W*H):

-

2100*2300*3400

-

Application:

-

fake fur, wollen fabric

-

Certificate:

-

CE ISO

-

Function:

-

sliver knitting

-

Needles:

-

91.75/88.82

-

Gauge:

-

14g

-

needle Nos:

-

1184

-

Main power:

-

7.5kw

-

Cylinder:

-

27"

-

Feeder:

-

18F

-

Software:

-

Pattern design system

Product Application

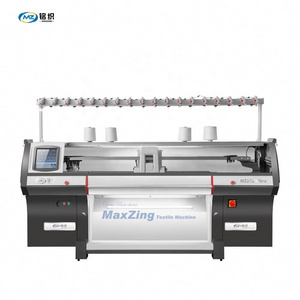

Computerized plain color faux fur fabric knitting machine

Modle:MS18-A,MS18-B

18-feeder computer-based artificial fur plain color Machine

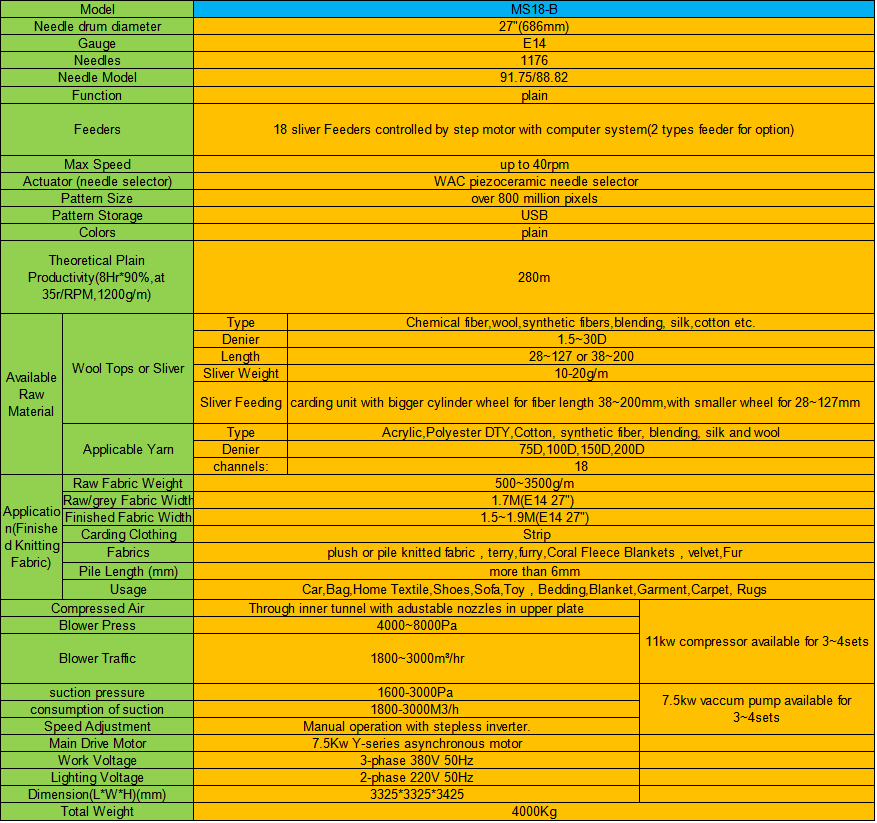

Machine parameters

Cylinder diameter: 27”/686mm

Cylinder grade: E14/ 1176/1056 needles

Feeds routes: 18

Cylinder speed: 35r/min

Main motor power: 7.5kw

Weaving needles model: 88.82/91.75

Features:

1. With complete up-to-date computer-controlled system, the status of knitting working condition, data of automatic fault diagnosis, automatic alarm or other related records could be displayed on the LED touch screen.

2. New added technology of broken needle detector improves the quality of jacquard knitting effectively.

3. The head of comb is designed to be more reasonable while the feeding speed and the top or sliver quantity are controlled more effectively, which make it adjustable according to the differences of fabric material, that widening its practical scope.

4. The design of adjustable tile can keep those rotating parts such as cylinders working in their best condition and rotating more smoothly and steadily. It can be much easier and more convenient to maintain the machines.

5. Cloth roller adapts magnetic-pull-control system, being the most advanced in the world. It is able to adjust the pull force according to requests, improving the fur weaving quality.

6. Both of "Uphill" angle and "downhill" angle use advanced "A" and "B" blocks in order to make working parts such as needle and sinker work with more accuracy and coordination. It is possible to make it a reality to freely change the blocks in the same places with similar blocks in a few minutes.

7. New improved density adjusting unit provides convenience and accuracy to adjust density of every route, which makes it easy to adjust the machine and simple to operate.

8. The storage space of cloth is increased, making it more suitable for production.

Machine Parts

Name: Electric magnetic clutch

ensure stable fabric pinching strength and avoid over pulling to damage the fabric.

Strong carding system

optimized carding unit can ensure the uniformed fiber blend and mixing, keep the sliver feeding speed in given speed and rate.

Double layer sinker applied(OPTIONAL)

with double layer sinker and cam combination, heavy duty high density high GSM fabrics can easy knitted without trouble.

computerized control system with windows system

it is very easy to change the pattern and machine operation due to industrial quality level touch LCD screen applied .

overseas after-sale service available at request of customers.

for first time installation and testing at customers' factory all related cost by user.