- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Bossman

-

Model Number:

-

BOSM-DS2020

-

Power (kW):

-

22

-

Weight (KG):

-

22000 KG

-

Product name:

-

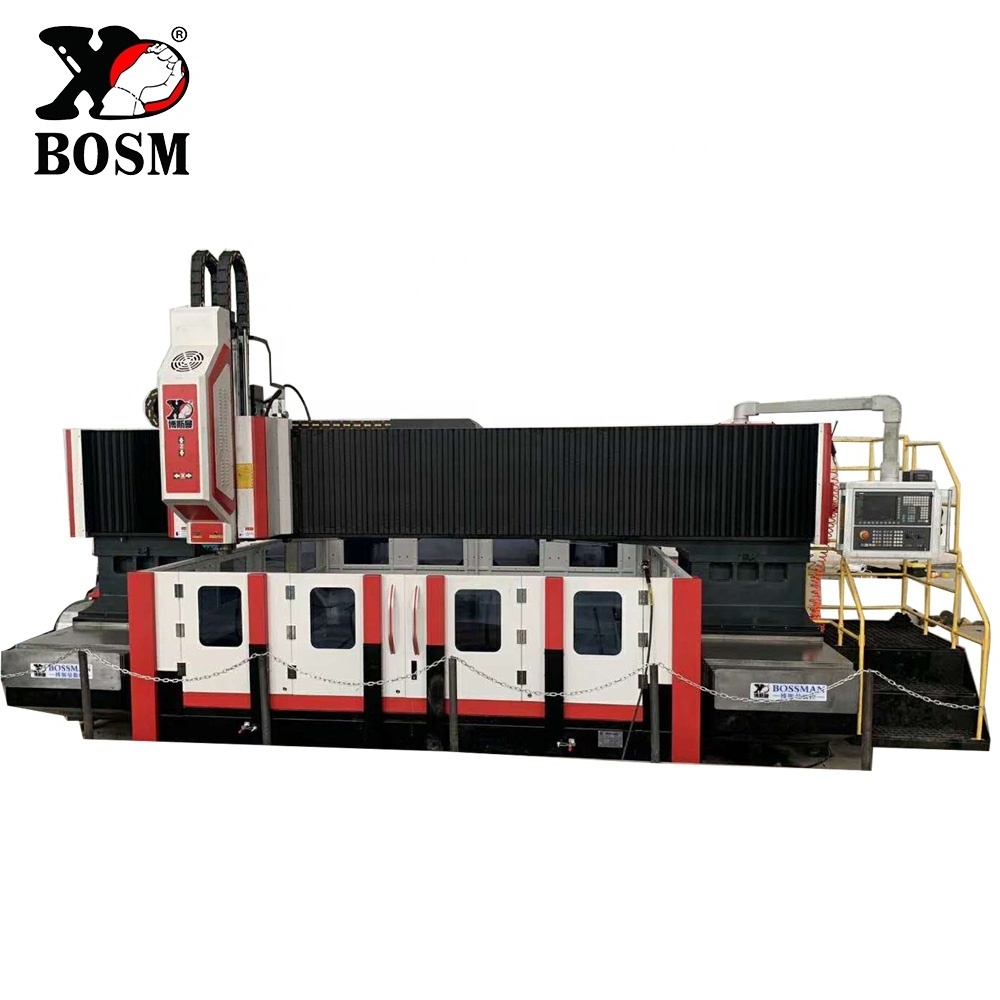

CNC Gantry Type Drilling And Milling Machine

-

Usage:

-

flanges, disks and rings

-

Color:

-

as shown

-

Machine type:

-

Gantry type Drilling machine

-

Table size:

-

2000*2000mm

-

Spindle taper:

-

BT50

-

Tapping diameter(mm):

-

M36

-

Servo Motor Power (kw):

-

2*4.2

-

Chip conveyor type:

-

Flat chain

-

Total motor power:

-

customizable

Quick Details

-

type:

-

Drilling & Milling Machine

-

Max. Drilling Dia. (mm):

-

90

-

Range of Spindle Speed(r.p.m):

-

30 - 300 r.p.m

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Bossman

-

Model Number:

-

BOSM-DS2020

-

Power (kW):

-

22

-

Weight (KG):

-

22000 KG

-

Product name:

-

CNC Gantry Type Drilling And Milling Machine

-

Usage:

-

flanges, disks and rings

-

Color:

-

as shown

-

Machine type:

-

Gantry type Drilling machine

-

Table size:

-

2000*2000mm

-

Spindle taper:

-

BT50

-

Tapping diameter(mm):

-

M36

-

Servo Motor Power (kw):

-

2*4.2

-

Chip conveyor type:

-

Flat chain

-

Total motor power:

-

customizable

Products Description

Heavy Duty CNC Gantry Drilling Machine Stack drilling machine for Shell and tube heat exchangers for engine cooling

Machine application:

The BOSSMAN CNC drilling and milling machines are mainly used for efficient drilling of workpieces with thicknesses within the effective range

such as plates, flanges, disks and rings.

Through-holes and blind holes can be drilled on different kinds of materials. The machine is digitally controlled with easy operation. It can achieve automation, high precision, multiple varieties, mass production.

In order to meet the processing needs of different users, our company has developed a variety of machines. In addition to conventional models, it can also be customized according to the actual needs of customers.

Machine Structure:

1)Worktable:

The bed is an integral casting, which is finished after secondary annealing and vibration aging treatment. It has good dynamic and static rigidity and does not deform.

2)Moving gantry:

The mobile gantry is made of gray iron (HT250), and two 55 # ultra-high-capacity rolling linear guide pairs are installed on the front side of the gantry.

3)Moving sliding saddle:

can realize the action of fast forward, industrial advance, fast retreat and stop of the power head. Chip breaking, chip removing, pause function.

4)Drilling power head(Spindle):

The spindle center water outlet function can improve the cutting efficiency, realize deep hole processing and protect the tool to reduce the use cost.

5)CNC Control System:

With chip breaking function, the tool lifting height can be set on the man-machine interface. the operation interface has functions such as man-machine dialogue, error compensation, and automatic alarm, has the function of previewing and rechecking the hole position before processing, and the operation is very convenient.

technical parameter

|

Model

|

|

BOSM-DS2020 CNC drilling&milling machine

(Heavy Duty Split Type

|

BOSM-DS2525 CNC drilling&milling machine

(Heavy Duty Split Type |

|

|||

|

Working Size

|

|

Length x Width (mm)

|

2000mm*2000mm

|

|

|||

|

|

|

T-slot width

|

28mm

|

|

|||

|

Vertical Drilling Head

|

|

Quantity

|

1

|

|

|||

|

|

|

Spindle taper

|

BT50

|

|

|||

|

|

|

Maximum drilling diameter (common carbon steel) (mm)

|

Φ90

|

|

|||

|

|

|

Drilling depth /

Drilling diameter(mm)

|

≤5

|

|

|||

|

|

|

Spindle Speed (r/min)

|

30~3000

|

|

|||

|

|

|

Tapping diameter(mm)

|

M36

|

|

|||

|

|

|

Spindle Motor Power (kw)

|

22(30optional)

|

|

|||

|

|

|

Distance from the under end of the spindle to the work surface

|

200-800mm(Standard)

|

|

|||

|

Gantry Longitudinal

Movement

(Y-axis)

|

|

Max. Travel (mm)

|

2000

|

|

|||

|

|

|

Moving Speed (m / min)

|

0~8

|

|

|||

|

|

|

Servo Motor Power (kw)

|

2X4.2

|

|

|||

|

Power Head Lateral

Movement (X Axis)

|

|

Max. Travel (mm)

|

2000

|

|

|||

|

|

|

Moving Speed (m / min)

|

0~8

|

|

|||

|

|

|

Servo Motor Power (kw)

|

4.2

|

|

|||

|

Vertical Ram Feed

Movement (Z-axis)

|

|

Max. Travel (mm)

|

600

|

|

|||

|

|

|

Moving Speed (m / min)

|

0~5

|

|

|||

|

|

|

Servo Motor Power (kw)

|

4.2

|

|

|||

|

Positioning Accuracy(X/Y/Z)

|

|

X/Y/Z

|

≤0.05

|

|

|||

|

|

|

|

|

|

|||

|

Repeat Positioning Accuracy(X/Y/Z)

|

|

X/Y/Z

|

≤0.03

|

|

|||

|

|

|

|

|

|

|||

|

Pneumatic system

|

|

Compressed air supply pressure

|

≥0.5MPa

|

|

|||

|

Chip removal and cooling

|

|

Chip conveyor type

|

Flat chain

|

|

|||

|

|

|

Chip remover qty.

|

2 pics

|

|

|||

|

|

|

Chip removal speed

|

1m / min

|

|

|||

|

|

|

Chip conveyor motor power

|

2X0.75kW

|

|

|||

|

|

|

Cooling method

|

Internal cooling (2MPa) + external cooling

|

|

|||

|

Automatic lubrication system

|

|

Lubrication pressure

|

2MPa

|

|

|||

|

|

|

Lubrication point filling amount

|

0.1mL

|

|

|||

|

|

|

Lubrication cycle

|

6-10min

|

|

|||

|

Electrical System

|

|

Control system

|

KND Bus Servo System

|

|

|||

|

|

|

CNC axis qty.

|

4

|

|

|||

|

Total motor power |

|

|

About 40Kw

|

|

|||

|

Machine size

|

|

Length x width x height

|

About 5000×5200×3600mm

|

|

|||

|

Weight

|

|

|

About 22 T

|

|

|||

Details Images

Quality Inspection:

Each machine of Bosman is calibrated with a laser interferometer from the United Kingdom RENISHAW company, which accurately inspects and compensates for pitch errors, backlash, positioning accuracy, and repeated positioning accuracy to ensure the machine's dynamic, static stability, and processing accuracy. . Ball bar test Each machine uses a ball bar tester from the British RENISHAW company to correct the true circle accuracy and machine geometric accuracy, and perform circular cutting experiments at the same time to ensure the machine's 3D machining accuracy and circle accuracy.

Sample show

Hot Searches