- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Fujian, China

-

Brand Name:

-

MINGPAI

-

Model NO.:

-

cellulose ether

-

HS Code:

-

3912900000

-

Production Capacity:

-

1, 50, 000 Mt/Year

-

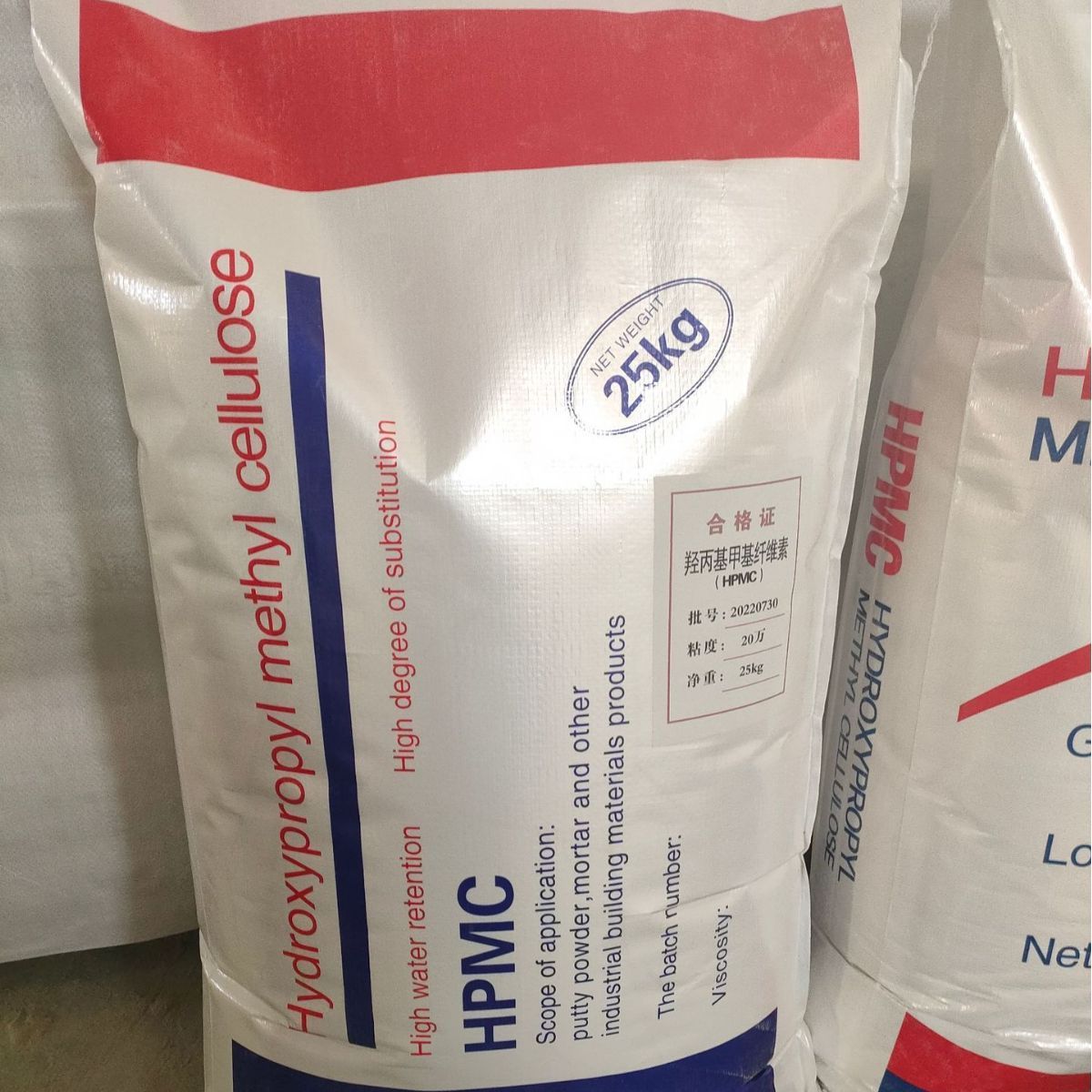

Transport Package:

-

25kg/Bag

-

Specification:

-

500-200, 000 mpa. s

-

Origin:

-

China

-

Customization:

-

Available

-

COMMON NAME:

-

HYDROXYPROPYL METHYL CELLULOSE

-

ABBREVIATION:

-

HPMC

-

STANDARDS COMPLIANT:

-

ENTERPRISE STANDARD

Quick Details

-

CAS No.:

-

9004-65-3

-

Other Names:

-

Viscosity Reducer Admixture

-

MF:

-

R=CH2CH(CH3)OH

-

Place of Origin:

-

Fujian, China

-

Brand Name:

-

MINGPAI

-

Model NO.:

-

cellulose ether

-

HS Code:

-

3912900000

-

Production Capacity:

-

1, 50, 000 Mt/Year

-

Transport Package:

-

25kg/Bag

-

Specification:

-

500-200, 000 mpa. s

-

Origin:

-

China

-

Customization:

-

Available

-

COMMON NAME:

-

HYDROXYPROPYL METHYL CELLULOSE

-

ABBREVIATION:

-

HPMC

-

STANDARDS COMPLIANT:

-

ENTERPRISE STANDARD

Product Description

PHYSICAL AND CHEMICAL PROPERTIES:

* Particle size: 98.5% passes through 100 mesh; 100% passes through 80 mesh.

* Charring temperature: 280-300ºC.

* Bulk density: 0.25-0.70 g/cm3 (Usually around 0.5 g/cm3 )

* Real specific gravity: 1.26-1.31.

* Browning temperature: 190-200ºC.

* Surface tension: (2% water solution) 42-56dyn.cm.

* Properties: Dissolved in water and some organic solvent such as ethanol. propyl alcohol. ethylene chloride, the water solution is of surface activity. It is a nonionic surface active agent. Gelation temperature is different for different grades. For example, among 60RT Hydroxypropyl Methylcellulose, 60 is gelation temperature, Namely, 2% water solution will form gelation at

60%.

* Charring temperature: 280-300ºC.

* Bulk density: 0.25-0.70 g/cm3 (Usually around 0.5 g/cm3 )

* Real specific gravity: 1.26-1.31.

* Browning temperature: 190-200ºC.

* Surface tension: (2% water solution) 42-56dyn.cm.

* Properties: Dissolved in water and some organic solvent such as ethanol. propyl alcohol. ethylene chloride, the water solution is of surface activity. It is a nonionic surface active agent. Gelation temperature is different for different grades. For example, among 60RT Hydroxypropyl Methylcellulose, 60 is gelation temperature, Namely, 2% water solution will form gelation at

60%.

Specification

|

INDEX

|

UNIT

|

TECHNICAL INDICATIONS

|

|

|

|

|

|

60SLO SERIES

|

75SLO SERIES

|

|

|

HYDROXYPROPYL

|

%

|

7.0-12.0

|

4.0-12.0

|

|

|

|

|

0.2-0.3 (DS)

|

0.1-0.3 (DS)

|

|

|

METHOXY

|

%

|

28.0-32.0

|

19.0-24.0

|

|

|

|

|

1.8-2.0 (DS)

|

1.1-1.6 (DS)

|

|

|

WATER

|

%

|

5.0 MAX

|

5.0 MAX

|

|

|

PARTICLE SIZE

|

%

|

90% THROUGH 250μm (ASTM MESH NO. 60)

80% THROUGH 125μm (ASTM MESH NO. 120) 80% THROUGH 106μm (ASTMMESH NO. 140) |

|

|

|

VISCOSITY (2% SOLUTION NDJ)

|

MPA.S

|

5-200000

|

|

|

|

GELLING TEMPERATURE

|

ºC

|

56-64

|

68-90

|

|

|

LIGHT TRANSMITTANCE

|

%

|

70 MIN

|

70 MIN

|

|

|

WHITENESS

|

%

|

75 MIN

|

75 MIN

|

|

|

PACKING DENSITY

|

G/L

|

370-420

|

|

|

|

APPEARANCE

|

|

WHITE OR ALMOST WHITE POWDER

|

|

|

|

|

Grade

|

Viscosity(2% NDJ)

|

Viscosity(2% Brookfield)

|

Tile Adhesive

|

Joint Filler

|

Cement Based Putty

|

Gypsum Based Putty

|

Gypsum Based Plaster

|

Masonry Mortar

|

|

HPMC |

KLD400

|

400

|

400

|

|

|

|

|

|

|

|

|

KLD4K

|

4,000

|

4,000

|

|

★

|

|

|

|

|

|

|

KLD15K

|

15,000

|

15,000

|

|

★★

|

|

|

|

|

|

|

KLD40K

|

40,000

|

20,000

|

|

★

|

|

|

|

|

|

|

KLD60K

|

60,000

|

30,000

|

|

|

|

|

★★

|

|

|

|

KLD80K

|

80,000

|

40,000

|

★★

|

|

★

|

★★

|

★

|

|

|

|

KLD100K

|

100,000

|

45,000

|

★★

|

|

★★

|

★

|

★

|

|

|

|

KLD150K

|

150,000

|

65,000

|

★★

|

|

|

|

★★

|

|

|

|

KLD200K

|

200,000

|

75,000

|

★

|

|

|

|

|

|

|

|

KLD200S

|

200,000

|

75,000

|

|

|

|

★★

|

|

|

|

HPMC-MAX |

KLD40M

|

40,000

|

20,000

|

★

|

★★

|

|

|

★

|

|

|

|

KLD60M

|

60,000

|

30,000

|

★

|

|

★★

|

★

|

★★

|

|

|

|

KLD80M

|

80,000

|

40,000

|

★★

|

|

|

★★

|

★★

|

|

|

|

KLD100M

|

100,000

|

45,000

|

|

|

★★

|

★

|

★★

|

|

|

|

KLD150M

|

150,000

|

65,000

|

|

|

|

|

★

|

|

Application Guide:

Tile Adhesive

Tile Adhesive

1. Using HPMC, tile adhesive will easy to mix with water without lump appeared and saving time. Due to the more

rapid and efficient operation, we can improve the workability and reduce the cost.

2. The water-retaining property of HPMC extend the drying time of mortar, so as to improve the efficient of fixing.

3. HPMC provide good bonding effect with highly skid resistance.

Cement-based plastering Mortar

rapid and efficient operation, we can improve the workability and reduce the cost.

2. The water-retaining property of HPMC extend the drying time of mortar, so as to improve the efficient of fixing.

3. HPMC provide good bonding effect with highly skid resistance.

Cement-based plastering Mortar

1. HPMC can improve the uniformity of plastering mortar, making it easy to coating, at the same

time improve the ability of anti-sag. It can also boost liquidity and pumpability of mortar, to improve the work efficiency.

2. With high water retention, HPMC can prolong the working time of mortar, improve work

efficiency, and help the mortar obtaining high mechanical strength in solidification period.

3. HPMC can control air infiltration, to eliminate the tiny cracks of coating, to format the ideal

smooth surface.

Masonry mortar

time improve the ability of anti-sag. It can also boost liquidity and pumpability of mortar, to improve the work efficiency.

2. With high water retention, HPMC can prolong the working time of mortar, improve work

efficiency, and help the mortar obtaining high mechanical strength in solidification period.

3. HPMC can control air infiltration, to eliminate the tiny cracks of coating, to format the ideal

smooth surface.

Masonry mortar

1. HPMC can improve the adhesiveness between mortar and masonry. And the water-retaining property of HPMC is

useful in raising the strength of mortar.

2. HPMC improves the lubricity and plasticity of mortar, so as to make the construction easier, to save time, to

reduce the cost.

3. For superabsorbent masonry, it is more important to use HPMC in the mortar.

Crack filler

useful in raising the strength of mortar.

2. HPMC improves the lubricity and plasticity of mortar, so as to make the construction easier, to save time, to

reduce the cost.

3. For superabsorbent masonry, it is more important to use HPMC in the mortar.

Crack filler

1. Excellent water retention of HPMC can prolong drying time of crack filler, it is helpful to improve work

efficiency. Also, the high lubricity makes construction easier and more smooth.

2. HPMC can improve the shrinkage resistance and crack resistance of crack filler, to perfect the surface quality.

3. HPMC makes the construction surface fine and smooth. Meanwhile, the adhesiveness get improved.

Gypsum-based plastering and gypsum products

efficiency. Also, the high lubricity makes construction easier and more smooth.

2. HPMC can improve the shrinkage resistance and crack resistance of crack filler, to perfect the surface quality.

3. HPMC makes the construction surface fine and smooth. Meanwhile, the adhesiveness get improved.

Gypsum-based plastering and gypsum products

1. HPMC can improve the uniformity of plastering mortar, making it easy to coating,at the same time improve the ability of anti-sag. It can also boost liquidity and pumpability of mortar, to improve the work efficiency.

2. With high water retention, HPMC can prolong the working time of mortar, improve

work efficiency, and help the mortar in obtaining high mechanical strength in solidification period.

3. HPMC can keep the consistency unified, forming a good surface.

Self-leveling floor materials

2. With high water retention, HPMC can prolong the working time of mortar, improve

work efficiency, and help the mortar in obtaining high mechanical strength in solidification period.

3. HPMC can keep the consistency unified, forming a good surface.

Self-leveling floor materials

1. The viscosity of HPMC has the effect of anti precipitation.

2. HPMC can enhance the product liquidity and pumpability, so as to improve the efficiency of the

flooring.

3. The water-retaining property of HPMC can avoid excess air infiltration. Therefore, crack and

contraction are greatly reduced.

Water-based paint and paint remover

2. HPMC can enhance the product liquidity and pumpability, so as to improve the efficiency of the

flooring.

3. The water-retaining property of HPMC can avoid excess air infiltration. Therefore, crack and

contraction are greatly reduced.

Water-based paint and paint remover

1. The suspension property of HPMC can prolong expiration date by prevent solid

precipitation. Meanwhile, it has good compatibility with other ingredients and biological stability.

2. HPMC helps the product dissolving rapidly without lump.

3. HPMC makes coating has good flow property and low splash, resulting a fine and smooth surface.

4. HPM can increase the viscosity of the paint remover, make it not out of work scope.

Contact us:Eric Phone:+86 130 5565 4873 Whasapp&Wechat: +86 130 5565 4873

precipitation. Meanwhile, it has good compatibility with other ingredients and biological stability.

2. HPMC helps the product dissolving rapidly without lump.

3. HPMC makes coating has good flow property and low splash, resulting a fine and smooth surface.

4. HPM can increase the viscosity of the paint remover, make it not out of work scope.

Contact us:Eric Phone:+86 130 5565 4873 Whasapp&Wechat: +86 130 5565 4873

SALES AND SERVICE NETWORK

Product packaging

|

Packaging Details

|

can cunstom Logo, 25kg/ bag

|

|

|

Twelve months from the date of production. If the storage is expired, it can still be used after re inspection

|

Twelve months from the date of production. If the storage is expired, it can still be used after re inspection

|

|

Hot Searches