- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

MM series

-

Product type:

-

Mould Fabrication as design requirement or sample

-

Mould material:

-

Ace50, P20, 718, 738, NAK80, S136 and so on

-

Mould base:

-

LKM,HASCO,or Mr.Mould customed

-

Mould life:

-

According to your requirement

-

Part Material:

-

ABS, PC, PA, PA66, POM and so on

-

CNC tolerance:

-

0.002 to 0.005 mm

-

Cavity:

-

Single/Family,as request

-

Tooling machine:

-

CNC , EDM , Engraving ,Wire-Cutting

Quick Details

-

Shaping Mode:

-

Plastic Injection Mould

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Mr.Mould

-

Model Number:

-

MM series

-

Product type:

-

Mould Fabrication as design requirement or sample

-

Mould material:

-

Ace50, P20, 718, 738, NAK80, S136 and so on

-

Mould base:

-

LKM,HASCO,or Mr.Mould customed

-

Mould life:

-

According to your requirement

-

Part Material:

-

ABS, PC, PA, PA66, POM and so on

-

CNC tolerance:

-

0.002 to 0.005 mm

-

Cavity:

-

Single/Family,as request

-

Tooling machine:

-

CNC , EDM , Engraving ,Wire-Cutting

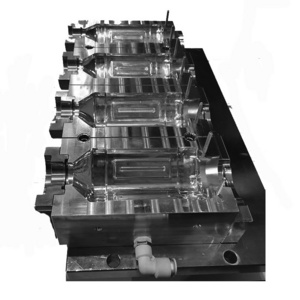

pc glass bottle mold

pc glass bottle mold

|

Mould Base |

LKM,HASCO,DME |

|

Cavity/core material |

2738,2343,S130,2344,718,8407,S136,P20,KD-61,NAK80,H13 ect |

|

Cavity QTY |

Single-cavity/Muti-cavity |

|

Runner |

cold/hot runner |

|

Gate |

Submarie gate,side/edge gate |

|

Mould lifetime |

500,000 shots |

|

Plastic part material |

PC,PA,ABS,PVC,PA66,TPE,SAN,POM.etc |

|

Lead time |

20-40 days based on different products |

|

Design sofeware |

UG/CAD/PROE |

Important Note:

1. The injection mould is customized for our clients.

2. We do not sell ready-made injection mould, but custom injection mould . So, no price list available.

3. Quotation available after discussion on requirements and design.

How To Custom My Own Injection Mould?

|

STEP |

DETAIL |

|

1.Enquire /Quote |

Discuss with customer after received buyer’s samples or drawings. |

|

2.Negotiation |

Quality,Technique requests,Mould material,Price,Delivery time,Payment,etc. |

|

3.Place order |

Sales contract + proforma invoice. |

|

4.prepaid |

Customer T/T deposit to us to start to design mould. |

|

5.Mould design |

We will communicate&exchange the opinion with customers during making drawing according to the sample. |

|

6.Design confirmation |

Send mould drawing to customer for confirmation. |

|

7.Mould processing |

Start to manufacture, we will sent photos to show tooling process. |

|

8.Sample confirm |

Send the sample or as negotiation. |

|

9.Mass production |

If customers need mass production plastic products, We can also offer. |

1. Our R&D center contains 2 industrial designers, 4 structure designers, 2 electronic engineers,

18 professtional mold design engineers, 8 CNC programmers .

2. Our mold making center equiped with 8 sets high-precision CNC machines, 8 sets EDM machine

2 sets WEDM(SODICK), 1set mirror EDM, 15 sets coordinate milling machines.

3. Our plastic products processing center has 25 sets of sophisticated C injection molding machine

with a clamping force from 80 to 800tons.

4. Advanced measurement equipment s- spectrograph(BRUKER), 2D Measuring Projector, CMM,

Surface Roughness Tester, Intellectual Hardness Tester, etc.

5. More than 12 -years experience.

6. ISO9001:200 8 certificated.

| Delivery time | 30 days after receipt the deposit |

| Packing |

Outside package : Standard wooden cases; Inner package : Stretch waterproof film & Each Mold painted anti-rust oil.3. Spare parts together with the mold shipment. |

Q1 How to have my components quoted ?

A1: Please contect us via TradManager or Email and send us your drawings inclusive of 2D and 3D(.STEP or .IGES files) and detail requirements. We are pleased to sign NDA with you if you prefer.

Then our engineering team will work on them and submit competitive quotation to you.

Q2 What is the lead time for tooling and samples fabrication?

A2: The exact lead time depends on your parts specification.

The normal lead time is 40-45days for tooling fabrication and samples.

If the tooling is not required, the lead time for samples is 15days normally.

Q3 Can I have prototypes for testing before tooling?

A3:Yes, our factory have team to support prototypes with machining process to fabricate them for your testing.

Q4 How to ship the samples and production order?

A4:We will normally ship samples via DHL, UPS, or FedEX via our cooperated forwaeder of freight collect.

For the shipping of production order, it will be by sea or by air.

Q5 How to ensure the quality of parts?

A5:Firstly,our team will inspect all incoming material. QC team will inspect parts while production and finished products, then submit Quality Inspection Report together with samples and production orther.