Main material:

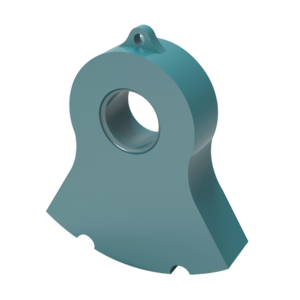

high manganese steel, manganese chromium alloy, high chromium (Cr13, Cr20, Cr23, Cr26, Cr28, etc.), carbide.

Casting process: V method, lost foam, water glass sand casting

Casting process: V method, lost foam, water glass sand casting