- Product Details

- {{item.text}}

Quick Details

-

Power:

-

5.4KW

-

Weight:

-

5000 KG

-

Dimension(L*W*H):

-

6690*700*1400 mm

-

Year:

-

2021

-

Name:

-

Automatic hard candy making machine

-

Function:

-

Multifunctional Candy Making Machine

-

Keywords:

-

Automatic Candy Making Machine

-

Material:

-

304 stainless steel hard candy making machine

-

Suitable for:

-

Candy Making Plants

-

Capacity:

-

150-600kg/h

-

Candy weight:

-

2-6g

-

Power Source:

-

Eletric candy making machine

-

Feature:

-

High Efficiency Easy Operation

-

Shape:

-

Clients' Demands

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

HNOC

-

Voltage:

-

380V

-

Power:

-

5.4KW

-

Weight:

-

5000 KG

-

Dimension(L*W*H):

-

6690*700*1400 mm

-

Year:

-

2021

-

Name:

-

Automatic hard candy making machine

-

Function:

-

Multifunctional Candy Making Machine

-

Keywords:

-

Automatic Candy Making Machine

-

Material:

-

304 stainless steel hard candy making machine

-

Suitable for:

-

Candy Making Plants

-

Capacity:

-

150-600kg/h

-

Candy weight:

-

2-6g

-

Power Source:

-

Eletric candy making machine

-

Feature:

-

High Efficiency Easy Operation

-

Shape:

-

Clients' Demands

Product parameter

|

Model

|

HNOC-H150

|

HNOC-H300

|

HNOC-H450

|

HNOC-H600

|

|

Standard production volume

|

150kg/h

|

300kg/h

|

450kg/h

|

600kg/h

|

|

Candy weight

|

2-6g

|

2-6g

|

2-6g

|

2-6g

|

|

Pouring rate

|

45-55n/min

|

45-55n/min

|

45-55n/min

|

45-55n/min

|

|

Steam demand

|

0.2m³/min

0.4-0.6Mpa

|

0.2m³/min

0.4-0.6Mpa |

0.2m³/min

0.4-0.6Mpa |

0.2m³/min

0.4-0.6Mpa |

|

Working environment

requirements

|

Temperature:

20-25℃

Humidity: 55%

|

Temperature:

20-25℃ Humidity: 55% |

Temperature:

20-25℃ Humidity: 55% |

Temperature:

20-25℃ Humidity: 55% |

|

Total power

|

18kw/380V

|

27kw/380V

|

34kw/380V

|

38kw/380V

|

|

Overall length

|

15m

|

17m

|

17m

|

20m

|

|

Overall weight

|

3500kg

|

4000kg

|

4500kg

|

5000kg

|

Product Description

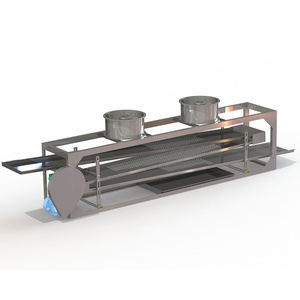

1. The hard candy production line is composed of an electric sugar cooker, a cooling table, a batching roller, a rope screen, a forming machine, a cooling screen, a packaging machine, etc. It can produce round, oval hard candies and columnar candies.

2. The entire production line has integrated electrical control and convenient operation and control. It is an ideal equipment for small and medium-sized candy companies.

|

Sugar melting pot

|

Sugar storage tank

|

Vacuum film sugar cooker

|

Pouring and forming unit

|

Cooling and conveying unit

|

|

Final products

|

Spherical lollipop packaging machine

|

Automatic cutting and packaging machine

|

Toffee (hard bubble gum) automatic dicing pillow packaging machine

|

1. Using famous-brand PLC, the performance is more stable, and the programming automatically controls the vacuum boiling temperature, time, holding temperature and pouring speed.

2. The 10.7-inch large touch screen displays the process flow chart, the working status of each part, the setting and display of parameters such as temperature, pouring speed, etc., making it easier for users to operate and master.

3. Frequency conversion speed control controls the accurate flow of sugar liquid, and the quality of massecuite is stable.

4. The dynamic mixer completes the quantitative filling and mixing of flavors, pigments, and acids online.

5. Conveyor belt, cooling system and double demoulding mechanism ensure demoulding.

6. Various shapes of candies can be produced according to different molds.

7. Replace part of the cooking and equipment and molds. This production line can produce soft candy series.

Hot Searches