- Product Details

- {{item.text}}

Quick Details

-

Function:

-

Wear-Resistant

-

Surface Treatment:

-

Glazed Tiles

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

KST

-

Model Number:

-

RT LINE

-

Type:

-

Tiles

-

Product name:

-

ceramic tile importers

-

Mounted technique:

-

lose piece

-

Thickness:

-

10mm

-

Combination:

-

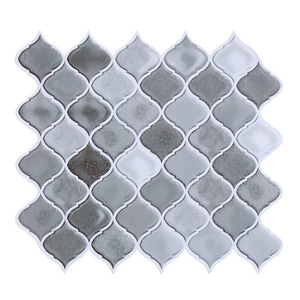

Free style, single or mix

-

Used:

-

Decorative materials

Quick Details

-

Project Solution Capability:

-

graphic design, 3D model design, total solution for projects, Cross Categories Consolidation

-

Application:

-

Apartment

-

Design Style:

-

Modern

-

Function:

-

Wear-Resistant

-

Surface Treatment:

-

Glazed Tiles

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

KST

-

Model Number:

-

RT LINE

-

Type:

-

Tiles

-

Product name:

-

ceramic tile importers

-

Mounted technique:

-

lose piece

-

Thickness:

-

10mm

-

Combination:

-

Free style, single or mix

-

Used:

-

Decorative materials

Product Description:

|

Product name |

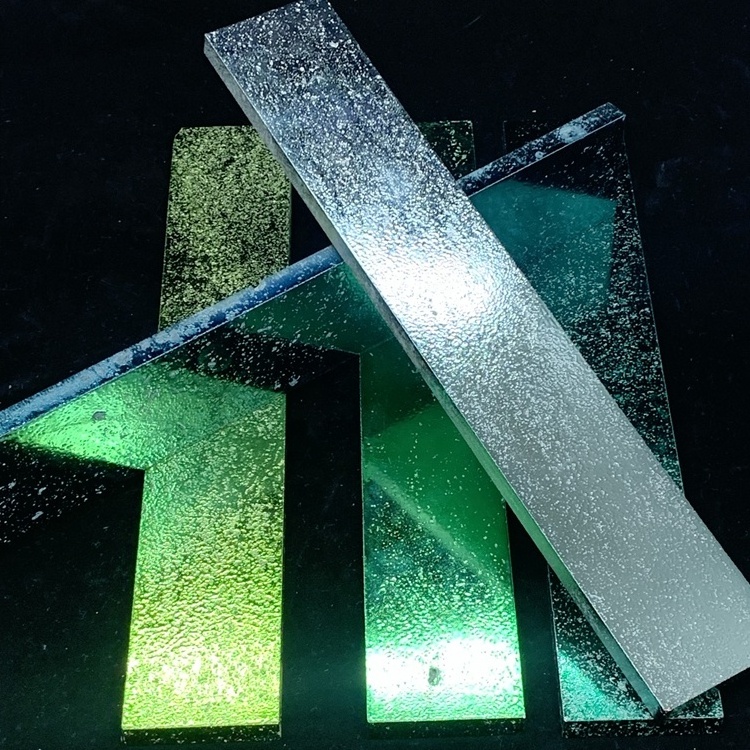

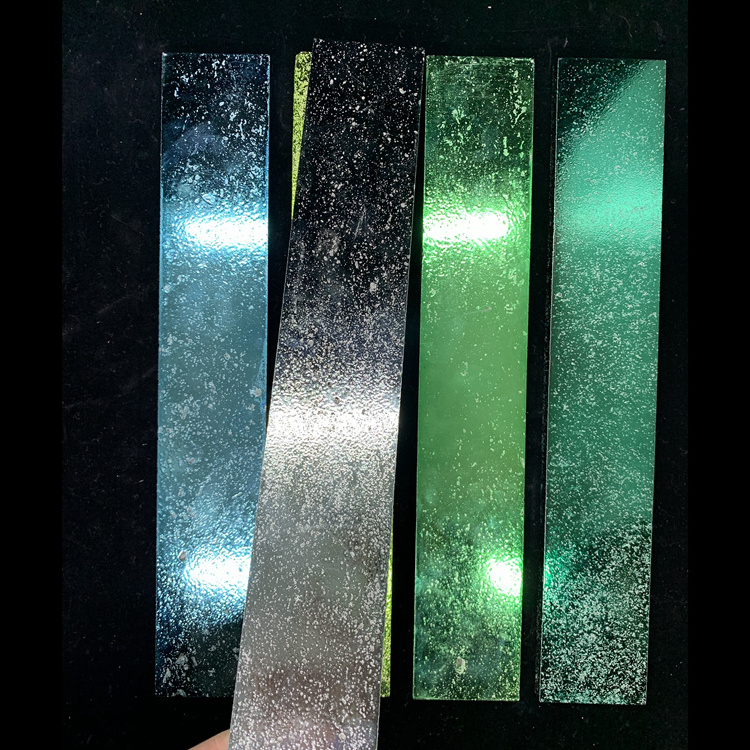

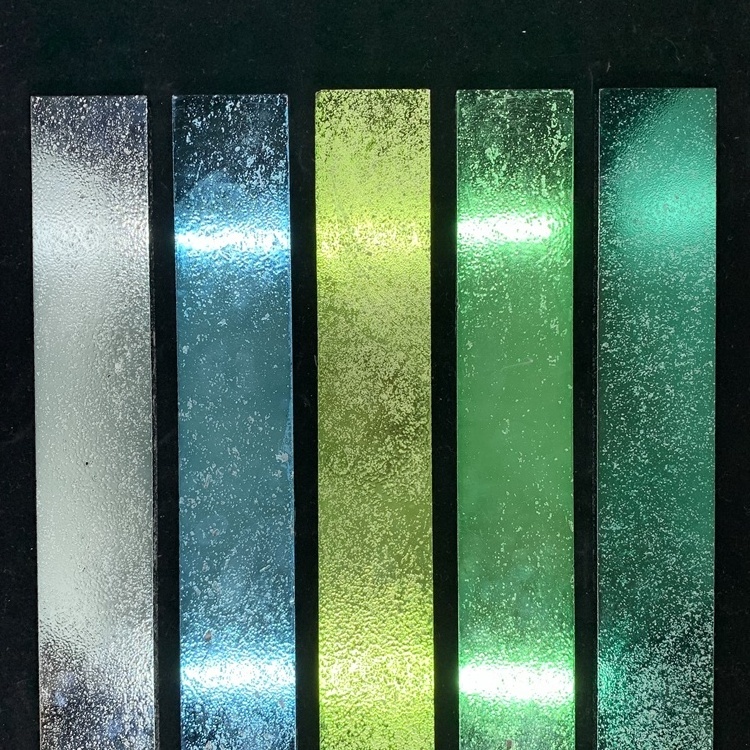

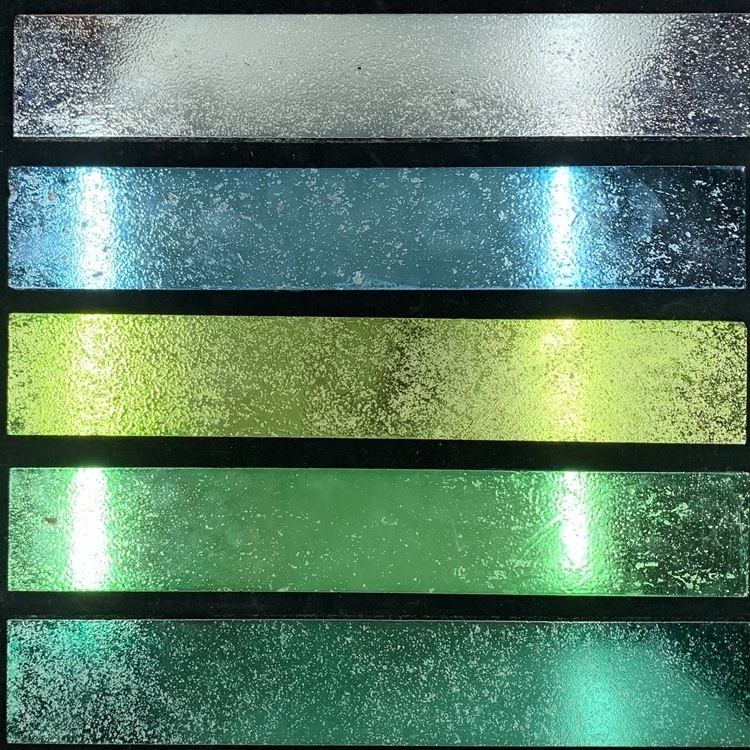

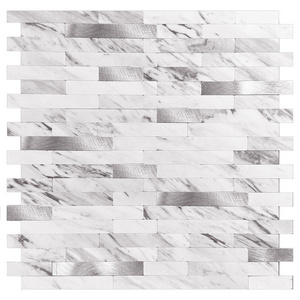

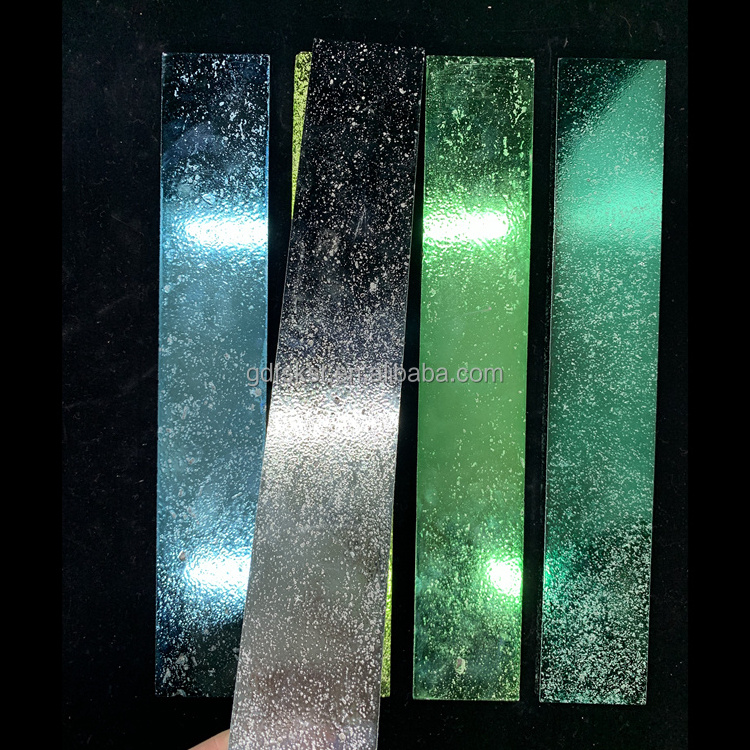

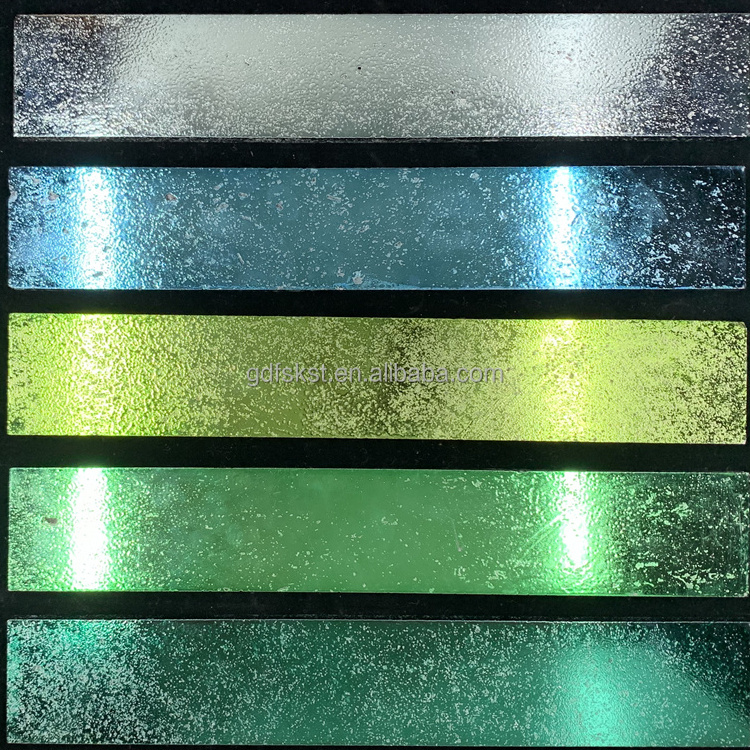

Electroplated tiles for wall decoration and hotel backsplash |

|

Tile Type |

marble Tiles |

|

Material |

marble |

|

Size |

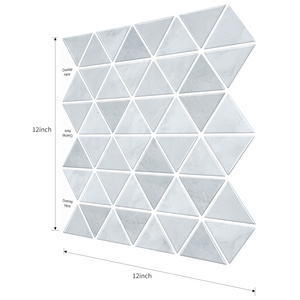

CHIPSIZE: 50*300mm |

|

Thickness(MM) |

10mm |

|

Water Absorption |

0.5% |

|

Color |

black and white |

|

Usage |

decrative materials |

|

Surface Treatment |

glossy |

|

Function |

Acid-resistant, Antibacterial, Non-Slip, Wear-Resistant |

|

Packaging |

Inner packing: plastic sheet, carton Outer packing: seaworthy wooden crate |

|

Delivery Time |

5-10days after the deposit is paid. |

|

MOQ |

20 square meters |

|

Supply Ability |

10000 square meters per day |

|

Remark |

All kind of designs can be produced according to your requirements. The production of custom patterns is supported. |

FAQ

Here are the most commonly asked questions:

|

Q1. Where is your factory? A1. In Nanzhuang Foshan China. |

|

Q2. What in your MOQ? A2. MOQ: 1x20’gp, can mix color in one container. |

|

Q3. What is the MOQ to use customer design carton? A3. MOQ: 5x20'gp. if less than this qty will charge for carton design draft fee. |

|

Q4. What is the MOQ for OEM? A4. 5000 sqm / model |

|

Q5. How you assure the quality? A5. We inspect the quality during incoming material, production process, packing and loading. |

|

Q6. What price you can offer? A6. EXW, FOB, CFR/ CIF, ect |

|

Q7. What payment you accept? A7. Normally By TT, L/C also acceptable. |