- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

HYDUN

-

Car Model:

-

VAN

-

Size:

-

58*48*55CM

-

Transmission Model:

-

Manual Transmission(MT)

-

Speed Ratio First Gear:::

-

3.251:1

-

Speed Ratio Second Gear::

-

1.955:1

-

Speed Ratio Third Gear:::

-

1.310:1

-

Speed Ratio Fourth Gear:::

-

1.100:1

-

Speed Ratio Fifth Gear:::

-

0.751:1

-

Engine Model::

-

2KD

-

GROSS Weight:

-

Approx 38KG

Quick Details

-

OE NO.:

-

OE Standard

-

Warranty:

-

1 Years

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

HYDUN

-

Car Model:

-

VAN

-

Size:

-

58*48*55CM

-

Transmission Model:

-

Manual Transmission(MT)

-

Speed Ratio First Gear:::

-

3.251:1

-

Speed Ratio Second Gear::

-

1.955:1

-

Speed Ratio Third Gear:::

-

1.310:1

-

Speed Ratio Fourth Gear:::

-

1.100:1

-

Speed Ratio Fifth Gear:::

-

0.751:1

-

Engine Model::

-

2KD

-

GROSS Weight:

-

Approx 38KG

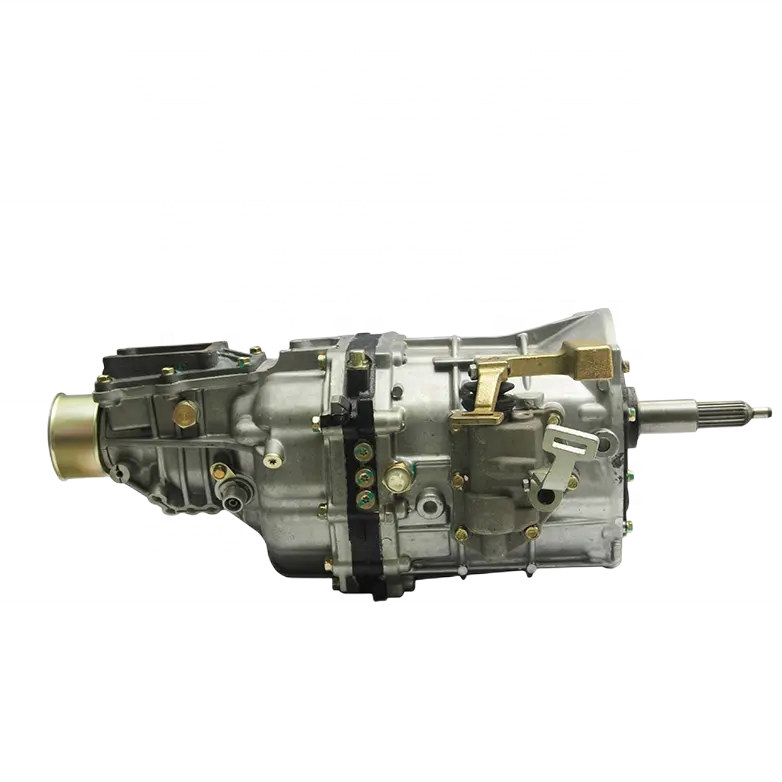

|

Product name

|

Manual Transmission Gearbox

|

|

Condition

|

NEW

|

|

Applicable models

|

For Toyota JINBEI 2KD HIACE Quantum

|

|

Notice

|

With no bell housing

|

|

Gross Weight

|

38KG

|

|

Compatibility

|

R154 Transmission

|

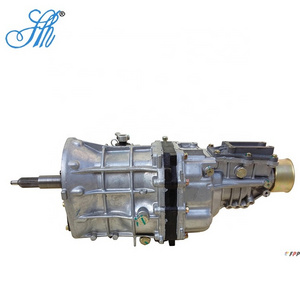

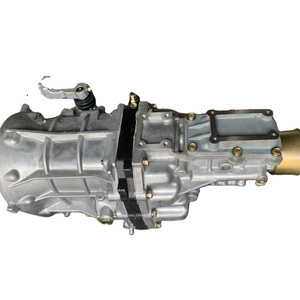

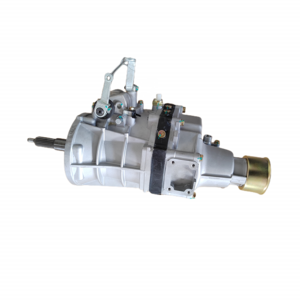

Factory Sale New Manual R154 Transmission Gearbox for Toyota JINBEI Hiace engine 2KD

Q:How the HRC of product surface can be reached?

A:The surface hardness reaches HRC58-63, and the core reaches HRC30-35.

Q:What equipment do you mainly use for processing?

A:We mainly use The Gleason gear milling machine from the United States for milling, Continuous carburizing furnace for heat treatment,Carburizing time is between 20-30 hours.

Q:What packaging do you use?

A:Put them together into a five-layer corrugated box,After packaging, we paste the model label. As shown.

Q: How long is the product warranty?

A: The normal warranty period of the gear is three months, Wrong geometry size, Overall fracture, Not installable, Cases of more than 20% of similar problems belong all to the Three Guarantees scope, we are responsible for replacement.

Q: Do you have your own product inspection equipment? What tests do you do?

A:A、After forging we test metallographic structure and hardness,B、During the processing, the geometry sizesare randomly tested.C、after heat treatment we check the metallographic structure and depth and hardness of the carburizing layer.D、We check the contact area, noise, and various geometry sizes before delivery. We have professional equipment and inspectors to complete it.

A:The surface hardness reaches HRC58-63, and the core reaches HRC30-35.

Q:What equipment do you mainly use for processing?

A:We mainly use The Gleason gear milling machine from the United States for milling, Continuous carburizing furnace for heat treatment,Carburizing time is between 20-30 hours.

Q:What packaging do you use?

A:Put them together into a five-layer corrugated box,After packaging, we paste the model label. As shown.

Q: How long is the product warranty?

A: The normal warranty period of the gear is three months, Wrong geometry size, Overall fracture, Not installable, Cases of more than 20% of similar problems belong all to the Three Guarantees scope, we are responsible for replacement.

Q: Do you have your own product inspection equipment? What tests do you do?

A:A、After forging we test metallographic structure and hardness,B、During the processing, the geometry sizesare randomly tested.C、after heat treatment we check the metallographic structure and depth and hardness of the carburizing layer.D、We check the contact area, noise, and various geometry sizes before delivery. We have professional equipment and inspectors to complete it.

Hot Searches