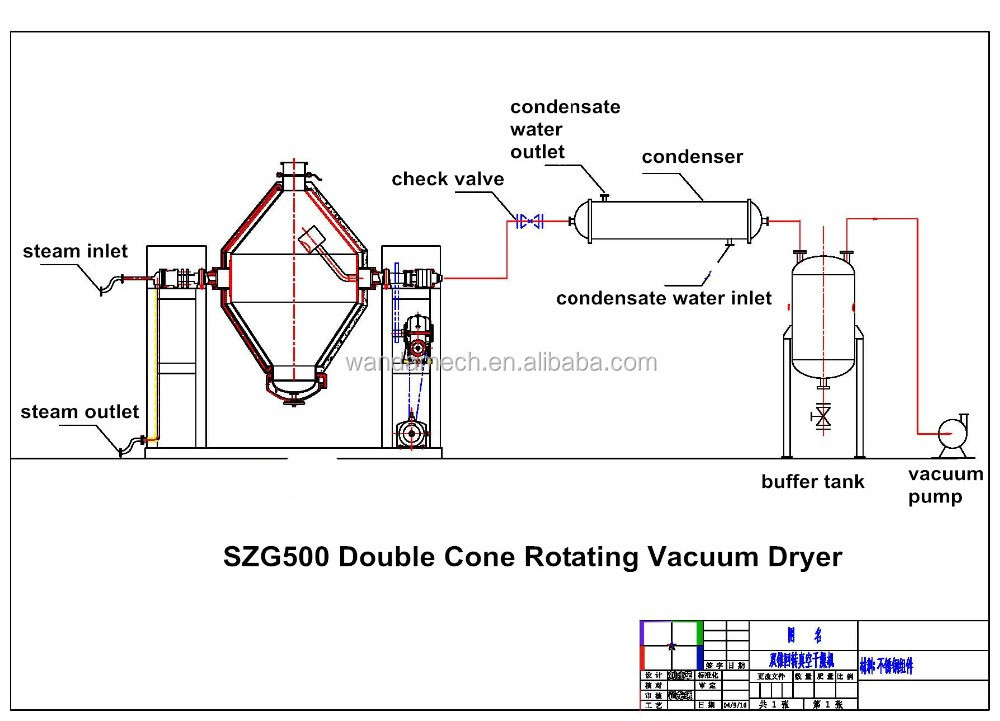

MIXING&DRYING

EASY OPERATION

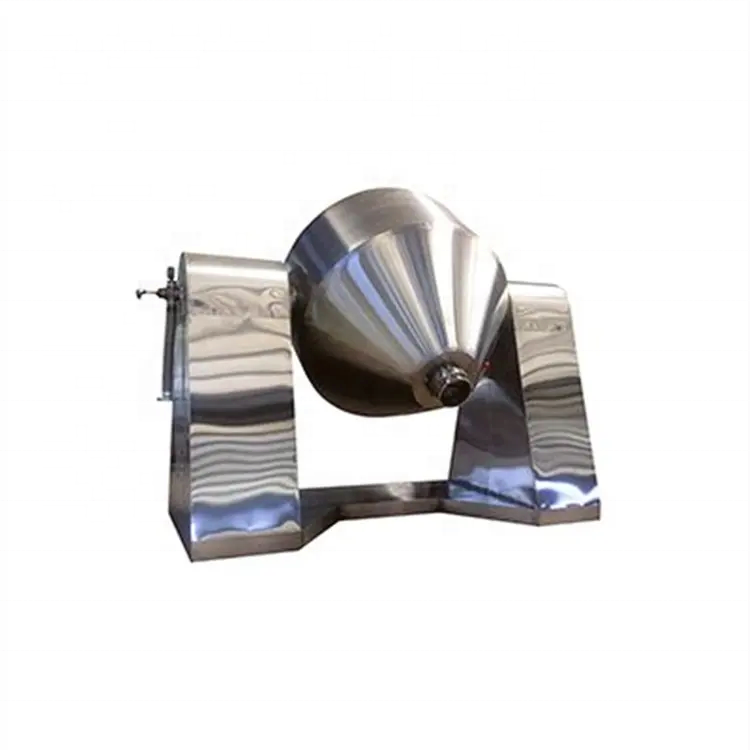

SAFETY STRUCTURE

SIMPLE CONTROL

EASY MAINTENANCE

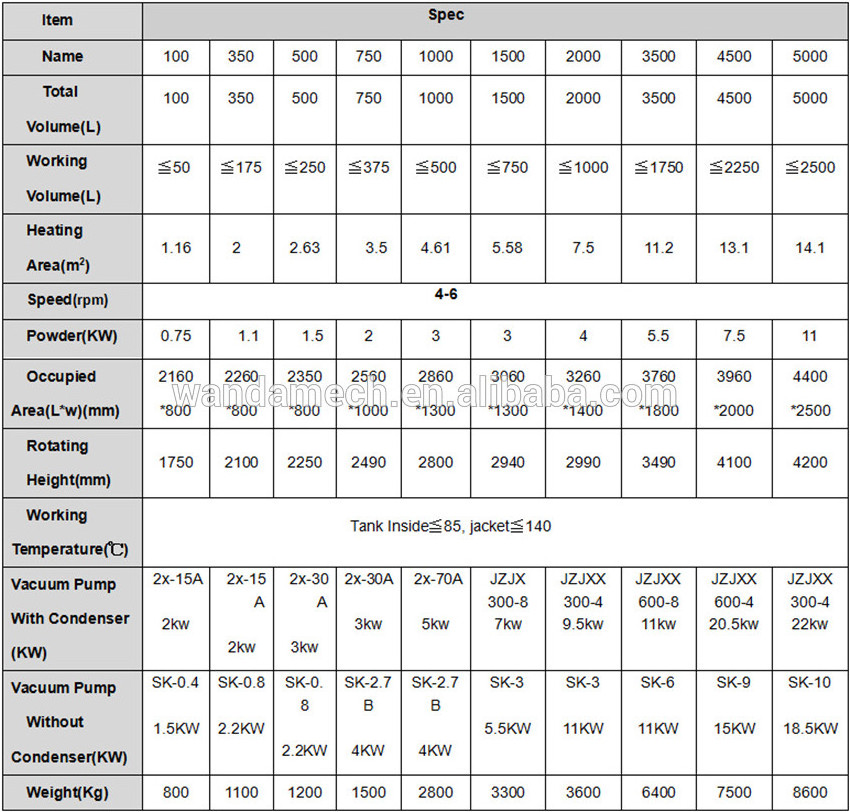

VARIOUS MODELS

LOW TEMPERATURE DRYING