- Product Details

- {{item.text}}

Quick Details

-

Positioning Accuracy (mm):

-

0.01 mm

-

Travel (X Axis)(mm):

-

2000 mm

-

Travel (Y Axis)(mm):

-

3000 mm

-

Repeatability (X/Y/Z) (mm):

-

0.01 mm

-

Spindle Motor Power(kW):

-

10kw

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

suntec

-

Voltage:

-

220V/380V

-

Dimension(L*W*H):

-

5100*4200*4000

-

Weight (KG):

-

16000

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

working area:

-

2000*3000*1000

-

Control system:

-

syntec control

-

Transmission:

-

Double Hiwin square orbit

-

Spindle:

-

10KW ITALY atc spindle

-

Driver:

-

japan yaskawa 2000w z axiswith brake

-

ATC:

-

you can choose (0/6/8)

-

working table:

-

cast iron table

-

spindle rotary:

-

A 110degree C 220 degree

-

invertor:

-

11kw Delta

Quick Details

-

Working Table Size(mm):

-

2000×3000

-

Machine Type:

-

CNC Router

-

Range of Spindle Speed(r.p.m):

-

1 - 24000 rpm

-

Positioning Accuracy (mm):

-

0.01 mm

-

Travel (X Axis)(mm):

-

2000 mm

-

Travel (Y Axis)(mm):

-

3000 mm

-

Repeatability (X/Y/Z) (mm):

-

0.01 mm

-

Spindle Motor Power(kW):

-

10kw

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

suntec

-

Voltage:

-

220V/380V

-

Dimension(L*W*H):

-

5100*4200*4000

-

Weight (KG):

-

16000

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

working area:

-

2000*3000*1000

-

Control system:

-

syntec control

-

Transmission:

-

Double Hiwin square orbit

-

Spindle:

-

10KW ITALY atc spindle

-

Driver:

-

japan yaskawa 2000w z axiswith brake

-

ATC:

-

you can choose (0/6/8)

-

working table:

-

cast iron table

-

spindle rotary:

-

A 110degree C 220 degree

-

invertor:

-

11kw Delta

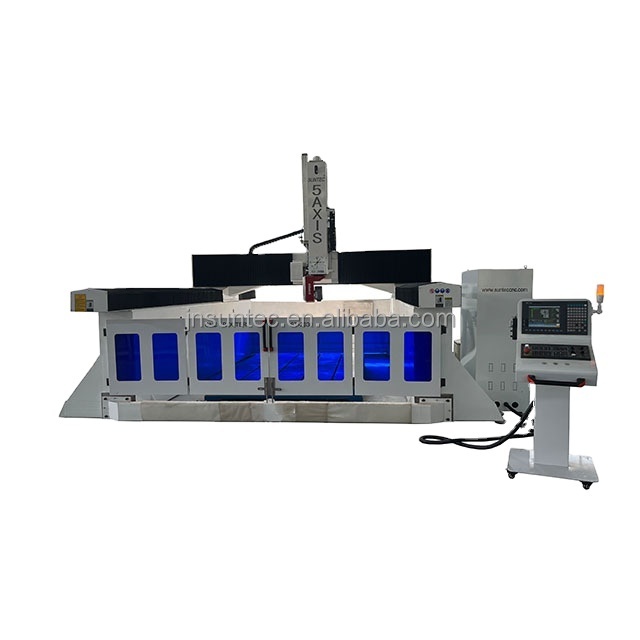

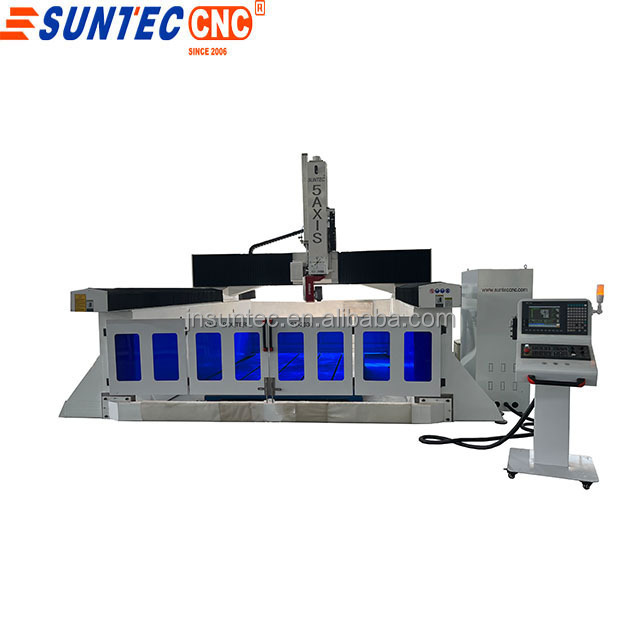

Suntec professional 3d aluminum wood styrofoam mold making 5 axis cnc router ST-2030

Main specification

1. The spindle can rotate

A +-110 ,C 220 +-

degree

can make multi-kinds of surface which we can design with Software.

2. We use top quality components for the machines, like

HSD spindle, Syntec EZ-21MA control system osai TPA, Delta Inverter, Yaskawa servo motors, and separate control box

, Hiwin linear and so on, to keep the machine in best condition even after many years working.

3. With hard steel structure, is fit for hard wood working, like cutting and engraving on Rosewood for furniture, indoor decoration. And with the Vacuum holding way and dust collector, the machine is qualified for mass- producing of furniture.

3.

this machine all model heat -treatment . the cast iron bed weight 35t . the total machine weight 65t . so no vibrating when working .

4. working size can customized 1300*2500*1000mm or 3500*6500mm or according your requirments

5. working table and structure according your material , Foam wood aluminum etc

6. MPG XYZAC Hand Wheel for easy origin and work piece setting.

7. Tool setting device.

8. One starter set woodworking tools.

9. 3 x collets, choice from 1-20mm (imperial available if preferred).

10. 1 x HSK 63F Tool Holder included.

11. Inverter: Taiwanese Delta Inverter 0-22000rpm control.

12. German Schneider Electronic Spare parts.

13. Japanese OMRON limit switches.

14. MAXICAM double sheathed, fire retardant and highly flexible towline cable can be bent 300,000 times.

15. Igus cable chain carrying system.

14. Voltage: 3PH 415V 50HZ.with transformer

15. RTCP (Rotated Tool Center Point), also known as TCPM,TCPC or RPCP, refers to the function maintaining rotary axes at constant angle between tool and surface to be machined. In 5-axis machining, the additional motion of the tool point is generated due to the rotary motion when following the tool point path and the angle between the tool and the workpiece. The control point of CNC system is often not coincident with the tool point, so the CNC system should automatically correct the control point to ensure that the tool point moves according to the given trajectory.

|

Number |

Description |

Parameter |

|

1 |

X,Y,Z Working Area |

2000*3000*1000mm |

|

2 |

Table Size |

2000×3000mm |

|

3 |

X,Y,Z Traveling Positioning Accuracy |

±0.01/1000mm |

|

4 |

A C ROTARY |

A 110 degree C 220 degree |

|

5 |

Table Surface |

cast iron table |

|

6 |

Frame |

Big Steel Tube Structure with heat treatment |

|

7 |

X, Y Structure |

Rack and Pinion Drive, Hiwin Rail Linear Bearings |

|

8 |

Z Structure |

Hiwin Rail Linear Bearings and Ball Screw |

|

9 |

Max. Power Consumption |

(Without Spindle) 10 Kw |

|

10 |

Max. Rapid Travel Rate |

40000mm/min |

|

11 |

Max. Working Speed |

30000mm/min |

|

12 |

Spindle Power |

10kw |

|

13 |

Spindle Speed |

0-24000RPM |

|

14 |

Drive Motors |

5000W Yaskawa Motors |

|

15 |

Working Voltage |

AC380V/50/60Hz,3PH (Option: 220V)) |

|

16 |

Command Language |

G Code |

|

17 |

Operating System |

Syntec Control System/TPA /osai |

|

18 |

Computer Interface |

USB |

|

19 |

Flash Memory |

512M |

|

20 |

Collet |

HSK-F63 |

|

21 |

X,Y Resolution |

<0.01mm |

|

22 |

Software Compatibility |

Type3/UcancameV9 powermill UG software |

|

23 |

Running Environment Temperature |

0 - 45 Centigrade |

|

24 |

Relative Humidity |

30% - 75% |

|

25 |

Packing Size |

5500X2100X2300mm |

|

26 |

N.W. |

16000KG |

|

27 |

G.W. |

18000kG |

|

28 |

Optional Parts |

Dust Collector/ Dust Hoods for three Axis |

|

Vacuum Pump |

||

|

Rotary System |

||

|

Mist-cooling System |

||

|

Delta/ Panasonic Servo Motors |

||

|

Colombo Spindle |

PRODUCTION DETAILS

After welding then table flat producing to make sure table at same lelve to make sure high precision

5 side milling center to milling square guide to make sure high precision

Sanding to reduct steelitsel dust to make sure paiting well and no scrab

All structure table heattreatment to deduct steel itself rigidity to make sure longlife use no deformed .

Heavy duty square gantry table milling by cnc center

Steel plate table with T slot to bear heavy duty material to make sure table no deformed

Installing

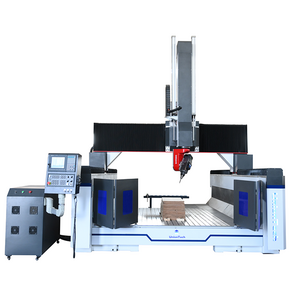

Italy Demas 5 axis head with 10 kw 24000 rpm atc spindle

Water chiller for cooling spindle to make spindle at sable working enviroment

air conditoner for cabinet box to make all driver constant weather

air plug for easily to loading unloading

syntec RCTP function

Renishaw to test four direction to make sure high precision

WORKING SAMPLE

SERVICE

1. 24 months guarantee of the whole cnc router machine,We will provide the consumable parts at an agency price when you need replacement.

2. Our engineer could support you technology to your contry if necessary.

3. Our enginner could service on weekend even on vacation.

4. Our engineer could train you on at our factory for free.

5. Our engineer could service you 24 hours online by skype, yahoo, msn, QQ, or by cellphone.

how to use software

1.During the design of the casting mold, input the three-dimensional drawing of the customer's product into the Solidworks software, set the parameters such as mold shrinkage and draft slope according to the casting process drawing of the product, and draw the three-dimensional drawing of the upper and lower molds.

2. Programming step by step according to the different surfaces of the mold, selecting the appropriate machining program, selecting the appropriate tool, spindle speed, feed speed, tool path step and other processing parameters to generate the tool path.

3. using software post processor come out NC format then can using cnc to milling it

4. if making wood , need rough milling with short cutter, then fine milling to make your mold .

package details

Other machine

60m length for blade power making

OUR COMPANY SHOW

RFQ

1. what material you deal with

2. what working size length width height

3. do you need make 1:1 rate

4. can you show us sample picture for our reference