- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Randro

-

Voltage:

-

Customized

-

Power:

-

7.5kw

-

Dimension(L*W*H):

-

6500x1500x1700mm

-

Weight:

-

5000 kg

-

Product name:

-

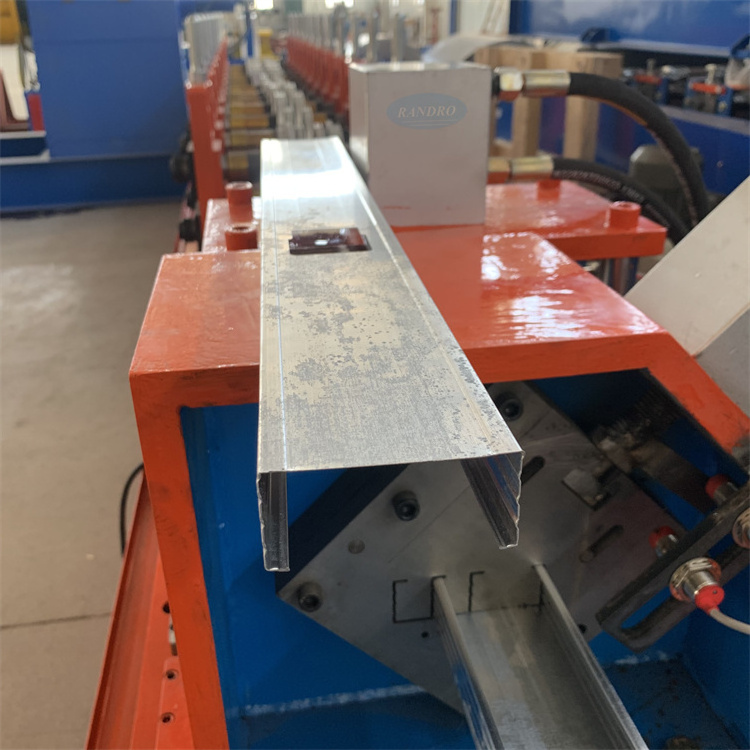

c z purlin roll forming machine

-

Keywords:

-

Profiled Purlin Equipment

-

Application:

-

Ceilling

-

Material:

-

Steel

-

Main Frame:

-

350H Steel

-

Thickness:

-

0.3--0.8mm

Quick Details

-

Marketing Type:

-

New Product

-

Work Pressure:

-

1000KN

-

Production Capacity:

-

10-15m/min

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Randro

-

Voltage:

-

Customized

-

Power:

-

7.5kw

-

Dimension(L*W*H):

-

6500x1500x1700mm

-

Weight:

-

5000 kg

-

Product name:

-

c z purlin roll forming machine

-

Keywords:

-

Profiled Purlin Equipment

-

Application:

-

Ceilling

-

Material:

-

Steel

-

Main Frame:

-

350H Steel

-

Thickness:

-

0.3--0.8mm

Products Description

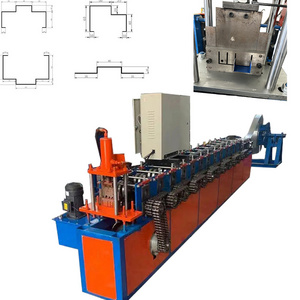

Fast Speed 3 in 1 PPGI GI C Stud U Channel Purlin Roll Forming Machine Small Keel Making Machine for Sale

3 in 1 multiple C Purlin Making Machine:

China manufacturer for metal stud and track roll forming machine CZ UVW keel cold roll forming machine

High speed light steel forming machine is designed to make the light steel, such as stud ,track, omega, angle,furring, channel etc. In batch fully automatically in the speed of maximum 80 meters per minutes. Compared with the common speed keel machine, high performance and efficiency equals to normal 2-3 times. This machine adopts servo motor,gearbox as transmission, servo tracking system. This high speed machine is popular among our customers home and abroad.

Key Parameters:

Forming step station: as per the profiles

Roll forming speed: max. 80m/min.

Total power: About 17 KW

Design type: Cast steel

Roller material: GCr12

Shaft material: Cr 40 steel

Transmission: gear box/Chains

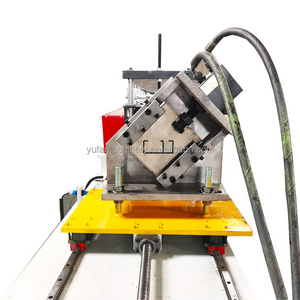

Type of cutting: Hydraulic

Cutting tolerance:±1mm

Cutter material: SKD11 imported from Japan

Forming step station: as per the profiles

Roll forming speed: max. 80m/min.

Total power: About 17 KW

Design type: Cast steel

Roller material: GCr12

Shaft material: Cr 40 steel

Transmission: gear box/Chains

Type of cutting: Hydraulic

Cutting tolerance:±1mm

Cutter material: SKD11 imported from Japan

Flow Working:

Decoiler→Roll Forming→Hydraulic Shearing→Out Of Table

Details Images:

3 in 1 profiles

Hydraulic Pump

Adjustable Feed Device

Hydraulic cutting system

rollers customized

Thick vertical plate

Product Parameters

|

Sn

|

Item

|

Technical Data

|

|

1

|

Profile

|

As per customers' requirememnts 3 in 1 profiles

|

|

3

|

Applicable Raw Material

|

PPGI,GI,PPGL,GL

|

|

4

|

Raw meterial thickness(mm)

|

0.3-3mm (optional)

|

|

5

|

Speed (m/min)

|

15m/min

|

|

7

|

Roller stations

|

10-16 (Customized);with heat treatment;HRC 58-60

|

|

9

|

Main Motor

|

4KW,5.5KW,7.5KW,11KW,15KW

|

|

10

|

Punching System

|

Optional

|

|

11

|

Hydraulic pump station

|

4KW,5.5KW,7.5KW,11KW;with Air fan cooling system

|

|

13

|

Transmission methos

|

chain/gear box

|

|

15

|

PLC control box

|

Delta/China famous brand/optional

|

|

16

|

Fast speed

|

( if required) customized

|

Product Process

Roller Die and the process of forming

Rollers are the most important components of the roll forming machine.

We need at least 7 steps to finish the rollers.

1. Base on the customer’s requirements, we cut the raw material in length and prepare the works of machining.

2. Roll die machining by CNC lathe;

3. Heat treatment for rollers;

4. Surface grinding machine for further fine machining;

5. Chrome coating

We need at least 7 steps to finish the rollers.

1. Base on the customer’s requirements, we cut the raw material in length and prepare the works of machining.

2. Roll die machining by CNC lathe;

3. Heat treatment for rollers;

4. Surface grinding machine for further fine machining;

5. Chrome coating

Process 1 Raw material for roller dies

Quality raw material for machining and fabrication in

Different sizes and sizes. We cut the raw material

based on our authorized roller design drawing.

Quality raw material for machining and fabrication in

Different sizes and sizes. We cut the raw material

based on our authorized roller design drawing.

Process 2 Roller die lathe machining

After cutting, then we use CNC lathe to do rollers machining.

It works by rotating the workpiece around a static cutting tool.

After cutting, then we use CNC lathe to do rollers machining.

It works by rotating the workpiece around a static cutting tool.

Process 3 Surface grinding machine

The surface grinding machine is used to provide precision surface and a smooth finish on flat surface,cuts chips of metallic substance from a workpiece making a face of it flat.

Process 4 Heat treatment for roller dies

Heat treatment is the most important processing for rollers,It can alter the physical and sometimes chemical, properties of a material.To remove stress, make the metal softer, refine

the structure or change its ductility.

Process 5 Chrome coating

Chrome coating is a technical electroplating of a thin layer of chrome on the rollers.Thus can provide corrosion resistance,ease cleaning procedures or increase surface hardness.Thus can prolong the roller dies life cycle.

Customers' Site Field Service

Application

China manufacturer for metal stud and track roll forming machine CZ UVW keel cold roll forming machine

high speed c purlin roll forming machine High Speed Frame Cad Supported C Channel Steel Roll Forming Machine.

Purlins are widely used for internal structural support of buildings, such as walls, roofs, and floors. Randro light steel keels can not only be used in residential construction, but are also widely used in commercial and industrial fields. Its areas of application also include the erection of lightweight steel structures, partition systems, ceiling and floor support systems, etc. Because light steel keels have the advantages of light weight, convenient construction, and corrosion resistance, they have received more and more attention and application in modern architectural design.

Hot Searches