- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220V 380v

-

Power:

-

6KW

-

Dimension(L*W*H):

-

2400 *1350 *1500mm

-

Weight:

-

1300 kg

-

Name:

-

Paper Cup Forming Machine

-

Finished Products:

-

paper cup

-

Raw material:

-

paper

-

Type:

-

Automtic

-

Function:

-

High Efficiency

-

After Warranty Service:

-

Video technical support

-

Top Diameter:

-

45mm(min)-90mm(max)

-

Bottom Diameter:

-

35mm(min)-70mm(max)

-

Height:

-

32mm(min)-135mm(max)

-

Paper:

-

150-350g/㎡;±20g/㎡

Quick Details

-

Production Capacity:

-

80-160 pcs/min

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

YUGONG

-

Voltage:

-

220V 380v

-

Power:

-

6KW

-

Dimension(L*W*H):

-

2400 *1350 *1500mm

-

Weight:

-

1300 kg

-

Name:

-

Paper Cup Forming Machine

-

Finished Products:

-

paper cup

-

Raw material:

-

paper

-

Type:

-

Automtic

-

Function:

-

High Efficiency

-

After Warranty Service:

-

Video technical support

-

Top Diameter:

-

45mm(min)-90mm(max)

-

Bottom Diameter:

-

35mm(min)-70mm(max)

-

Height:

-

32mm(min)-135mm(max)

-

Paper:

-

150-350g/㎡;±20g/㎡

Product Description

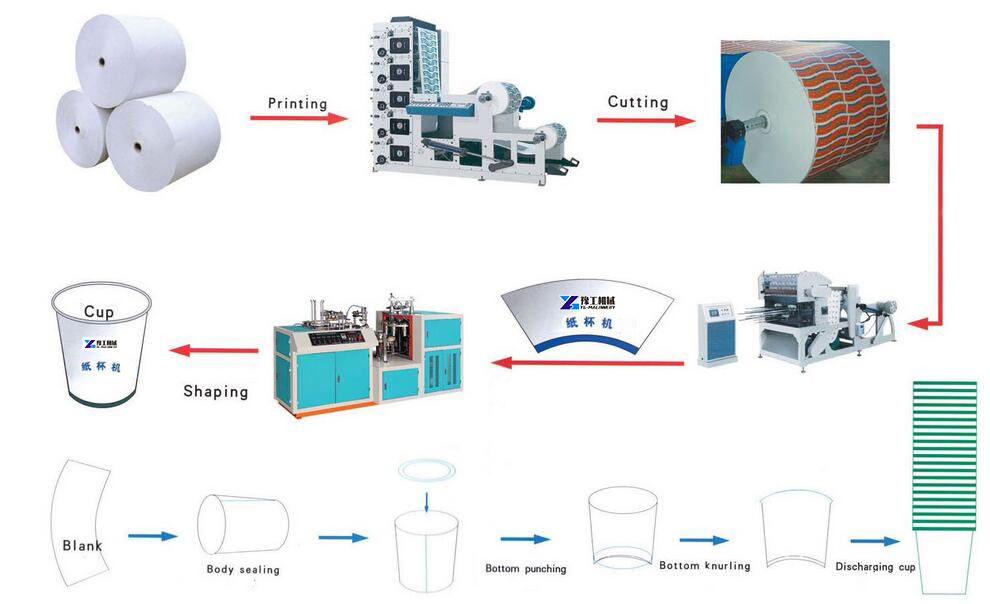

Paper Cup Forming Machine

Our paper cup machine can customize 3-16 oz single and double coated paper cups according to customer requirements. It is a fully automatic paper cup forming equipment that uses multi-row automatic paper feeding, paper anti-reverse device (to ensure accurate positioning), ultrasonic or copper strip welding, robot paper tube transfer, oil filling, bottom punching, bottom folding, preheating, and rolling. Continuous processes such as flowering and cup unloading can stably produce paper cups of various specifications. It is a paper cup equipment independently developed by our company that has undergone comprehensive technical improvements to improve the stability of the whole machine.

Specification

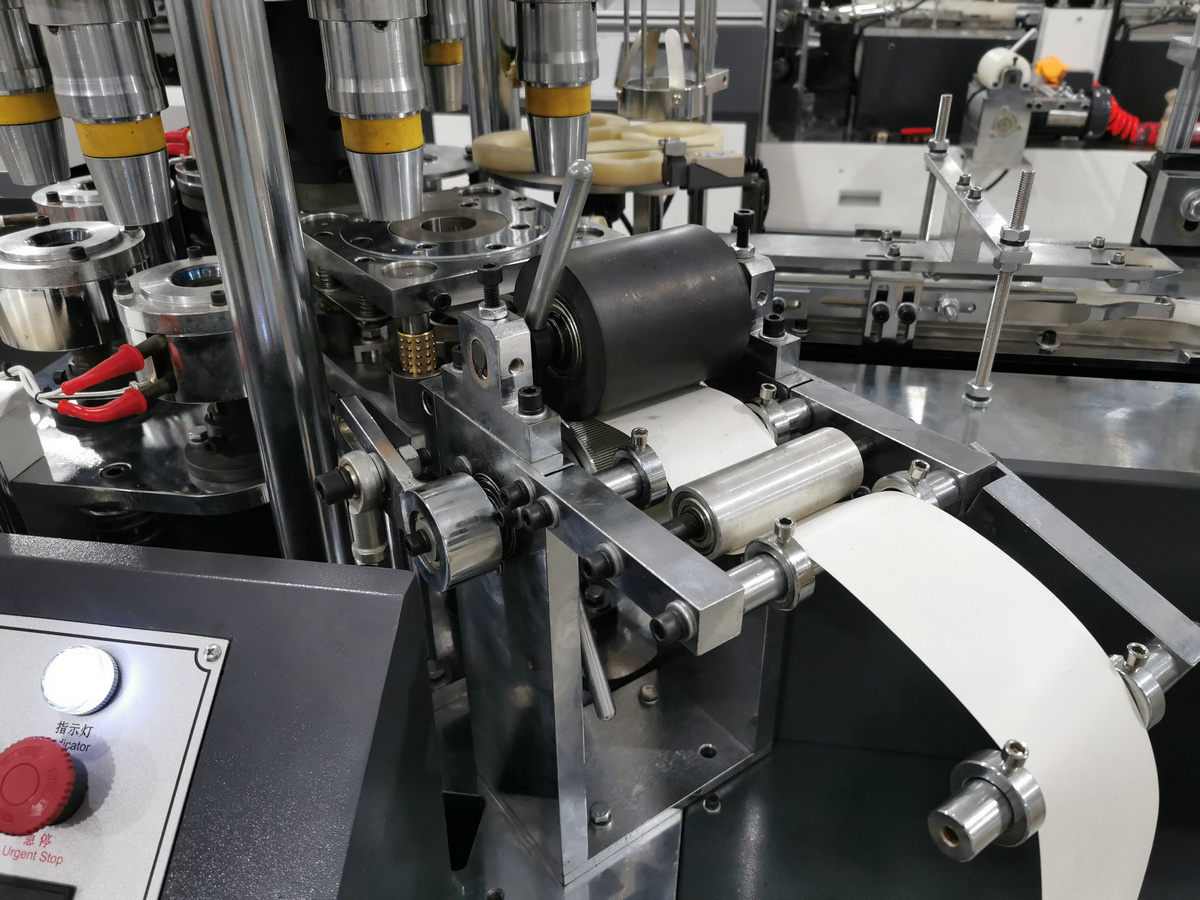

Reliability:

Intelligent medium speed paper cup forming machine has the advantages of high performance, high efficiency and high quality. The

whole steel plate body and oil injection lubrication system ensure the long-term normal and stable operation of the equipment.

whole steel plate body and oil injection lubrication system ensure the long-term normal and stable operation of the equipment.

Foreign technology and Chinese manufacturing:

The paper base heating system (Leidin, Switzerland) uses 2-step flameless heating.

Every step in production is monitored and reported by photocell (Omron Japan).

High energy efficiency:

Advanced high precision cylindrical CAM drive unit with gear transmission system to ensure the accurate

work of each station. Feed paper with servo tracking system control, effectively save raw paper. Foreign technology and Chinese

work of each station. Feed paper with servo tracking system control, effectively save raw paper. Foreign technology and Chinese

|

Top Diameter

|

45mm(min)-90mm(max)

|

|

|

|

Bottom Diameter

|

35mm(min)-70mm(max)

|

|

|

|

Height

|

32mm(min)-135mm(max)

|

|

|

|

Raw material

|

160-300 GRAM

|

|

|

|

Configuration

|

Ultrasonic & Hot air system

|

|

|

|

Output

|

6KW,380V/50HZ

|

|

|

|

Air compressor

|

0.4 M³/Min 0.5MPA

|

|

|

|

Net weight

|

1700kg

|

|

|

Details

Packing & Delivery

Hot Searches