- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Topway

-

Voltage:

-

380V

-

Power (kW):

-

37

-

Weight:

-

7000 KG

-

Product name:

-

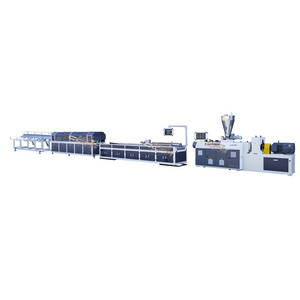

WPC Wood Plastic Profile Extrusion Production Line

-

Raw material:

-

WPC

-

After-sales Service Provided:

-

Engineers

-

Final product:

-

Wood Plastic Composite Products

-

Usage:

-

Plastic Extrusion

-

Keywords:

-

Profile Extrusion Machine

-

Product Type:

-

WPC Board

-

After Warranty Service:

-

Within One Year

-

Application Field:

-

Hot Forming Products

-

Processed Material:

-

PVC WPC Composite Powder

Quick Details

-

Screw Design:

-

Double-screw

-

Screw L/D Ratio:

-

33:1

-

Screw Speed (rpm):

-

65 rpm

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Topway

-

Voltage:

-

380V

-

Power (kW):

-

37

-

Weight:

-

7000 KG

-

Product name:

-

WPC Wood Plastic Profile Extrusion Production Line

-

Raw material:

-

WPC

-

After-sales Service Provided:

-

Engineers

-

Final product:

-

Wood Plastic Composite Products

-

Usage:

-

Plastic Extrusion

-

Keywords:

-

Profile Extrusion Machine

-

Product Type:

-

WPC Board

-

After Warranty Service:

-

Within One Year

-

Application Field:

-

Hot Forming Products

-

Processed Material:

-

PVC WPC Composite Powder

Product Description

● Professional Plastic Machinery Manufacturer

● High Quality

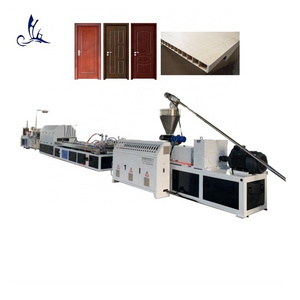

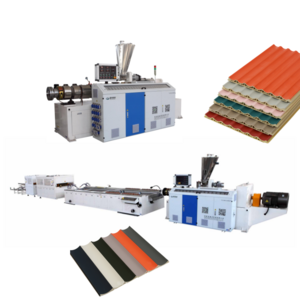

Wood Plastic Composite Extrusion Line

● WPC

Floor Profile Making Machine

●

WPC Door Board Extrusion Line

>>WPC (Wood Plastic Composite) Extrusion Line Introduce

Wood-plastic profiles are a new type of building decoration material, which are fully mixed with PVC, PP, PE and other plastics and various plant fibers, extruded and vacuum sized.

Mold can design different types of profiles according to customer requirements.

WPC wood plastic products have the advantages of corrosion resistance, high strength, recyclable,ect.

>>Product Application

Decking floor,

floor profile,

outdoor floor,

fence,

pegola,

s

olid door frame,

door farme,

window frame,

wall panel,

greating wall panel,

Wood-plastic interior doors, baseboards, integral cabinets, closets, exterior wall panels ,ect.

Twin screw extruder

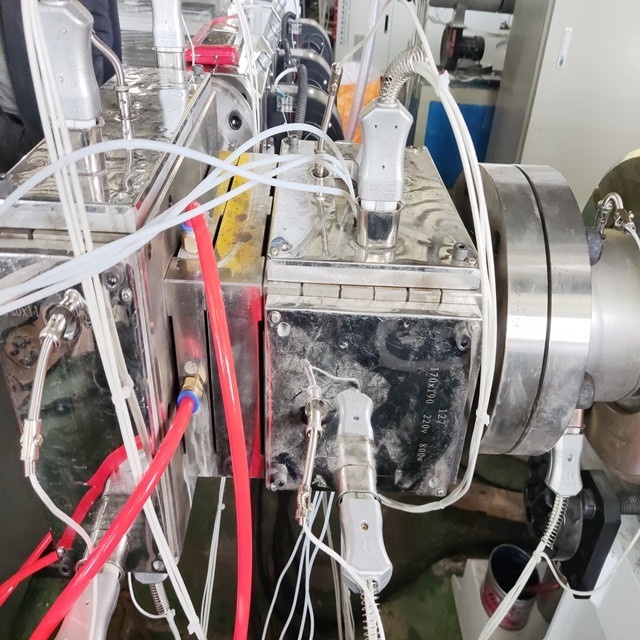

Die head mould

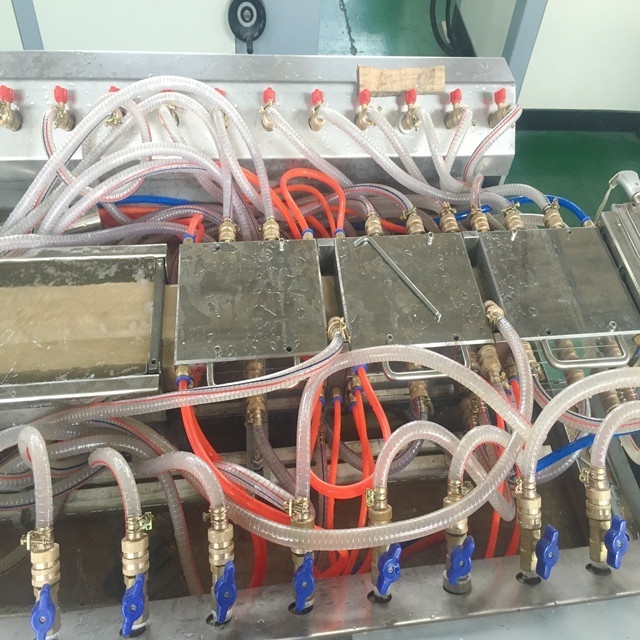

Calibrating and cooling device

Haul-off

and cutting machine

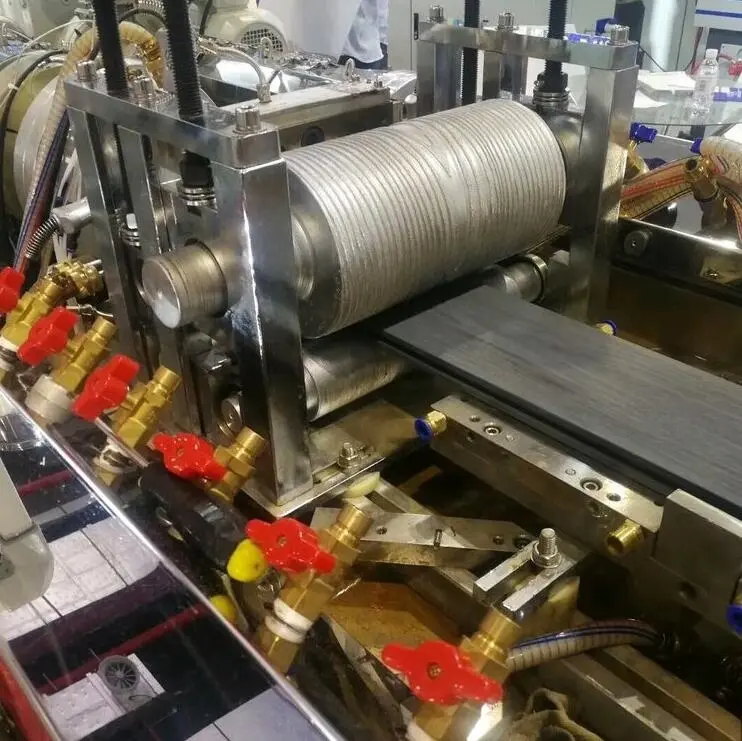

WPC Embossing m

achine

Stacker

Wood Profile Process Flow

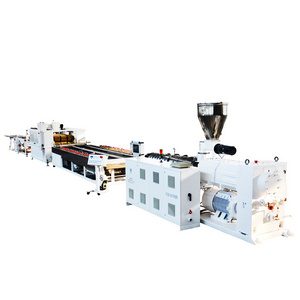

Concial Twin Screw Extruder

It adopts 38CrMoAl high-quality screw, which has been nitrided; it adopts high-quality reduction box, helical gear transmission, and has been nitrided and polished.

Vacuum Calibration Table

The length of the vacuum tank is customized, and the water channel and tank are made of stainless steel.

Length and width can be customized on request.

Haul-Off Machine

It adopts synchronous traction of upper and lower crawler tracks, variable frequency speed regulation, constant traction speed, compact structure and simple operation.

Cutting Machine

Adopting pneumatic control saw blade cutting, with reasonable design, stable operation, automatic fixed length cutting, high cutting accuracy, and smooth cut.

Machine Composition

|

No.

|

Machine Name

|

Qty

|

|

1

|

Screw Loading Machine

|

3 sets

|

|

2

|

SHR-500 High Speed Mixer

|

1 set

|

|

3

|

SHJ-75 Parallel Twin Screw Pelletizing Machine

|

1 set

|

|

4

|

SJSZ-65/132 Profile Extrusion Line

|

1 set

|

|

5

|

Calibrating and cooling device

|

1 set

|

|

6

|

Haul-off machine

|

1 set

|

|

7

|

Cutting Machine

|

1 set

|

|

8

|

Stacker

|

1 set

|

|

9

|

WPC Decking Moulds

|

1 set

|

|

10

|

WPC Embossing Machine

|

1 set

|

|

11

|

WPC Sanding Machine

|

1 set

|

|

12

|

WPC Brushing Machine

|

1 set

|

Product Application

Wood Plastic Composite products extrusion line Main products:

1) PP/PE WPC profile extrusion line for making outdoor decking,fence, post, pallet, flooring, chair, wall panel and ceiling panel etc.

2) PVC WPC profile extrusion line for making window and door frames, wall panel and ceiling panel etc.

3) PVC WPC door panel extrusion line for making door panel.

4) PVC WPC foam board extrusion line for making furniture,partition,poster board,etc.

Packing And Shiping

Hot Searches