In strong wooden case(s), suitable for long-distance ocean/parcel post/air freight or land transportation and to change of

climate, well protected against moisture and shocks.

- Product Details

- {{item.text}}

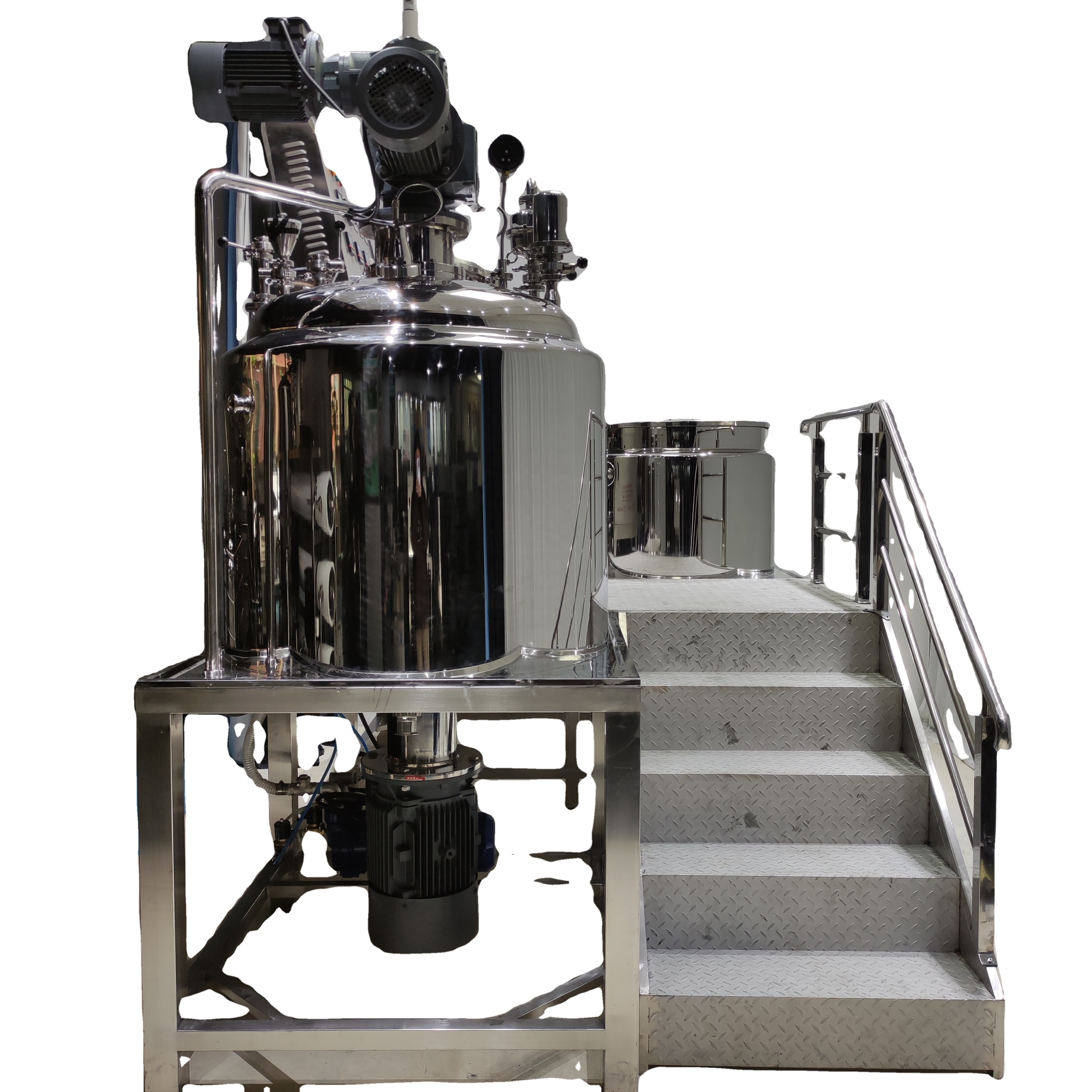

Quick Details

-

Weight (KG):

-

2000 KG

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

AILUSI

-

Voltage:

-

120V/220V/380V/440V

-

Power (kW):

-

16.5 kW

-

Function:

-

Mixing,Homogenizing,Emulsion

-

Mixing type:

-

Frame oar scrape stirrer

-

Structure:

-

Combined water and oil phase, main emulsion pot

-

Motor:

-

Siemens, Delta, Schneider, Delixi etc

-

Control:

-

Buttons/PLC control

-

Homogenizer:

-

High shearing rotor and stator homogenizing

-

Discharge:

-

Tilting discharge and bottom outlet

-

Certification:

-

ISO/CE

-

MOQ:

-

1 Set

-

Machine Type:

-

Dispersion Blender Mixer Machine

Quick Details

-

Barrel Volume (L):

-

500

-

Max. Loading Volume (L):

-

600 L

-

Range of Spindle Speed(r.p.m):

-

0 - 65 r.p.m

-

Weight (KG):

-

2000 KG

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

AILUSI

-

Voltage:

-

120V/220V/380V/440V

-

Power (kW):

-

16.5 kW

-

Function:

-

Mixing,Homogenizing,Emulsion

-

Mixing type:

-

Frame oar scrape stirrer

-

Structure:

-

Combined water and oil phase, main emulsion pot

-

Motor:

-

Siemens, Delta, Schneider, Delixi etc

-

Control:

-

Buttons/PLC control

-

Homogenizer:

-

High shearing rotor and stator homogenizing

-

Discharge:

-

Tilting discharge and bottom outlet

-

Certification:

-

ISO/CE

-

MOQ:

-

1 Set

-

Machine Type:

-

Dispersion Blender Mixer Machine

AILUSI Machinery

Manufacturer of Cosmetic | Food | Daily Chemical industrial | GMP Standard

Product Description

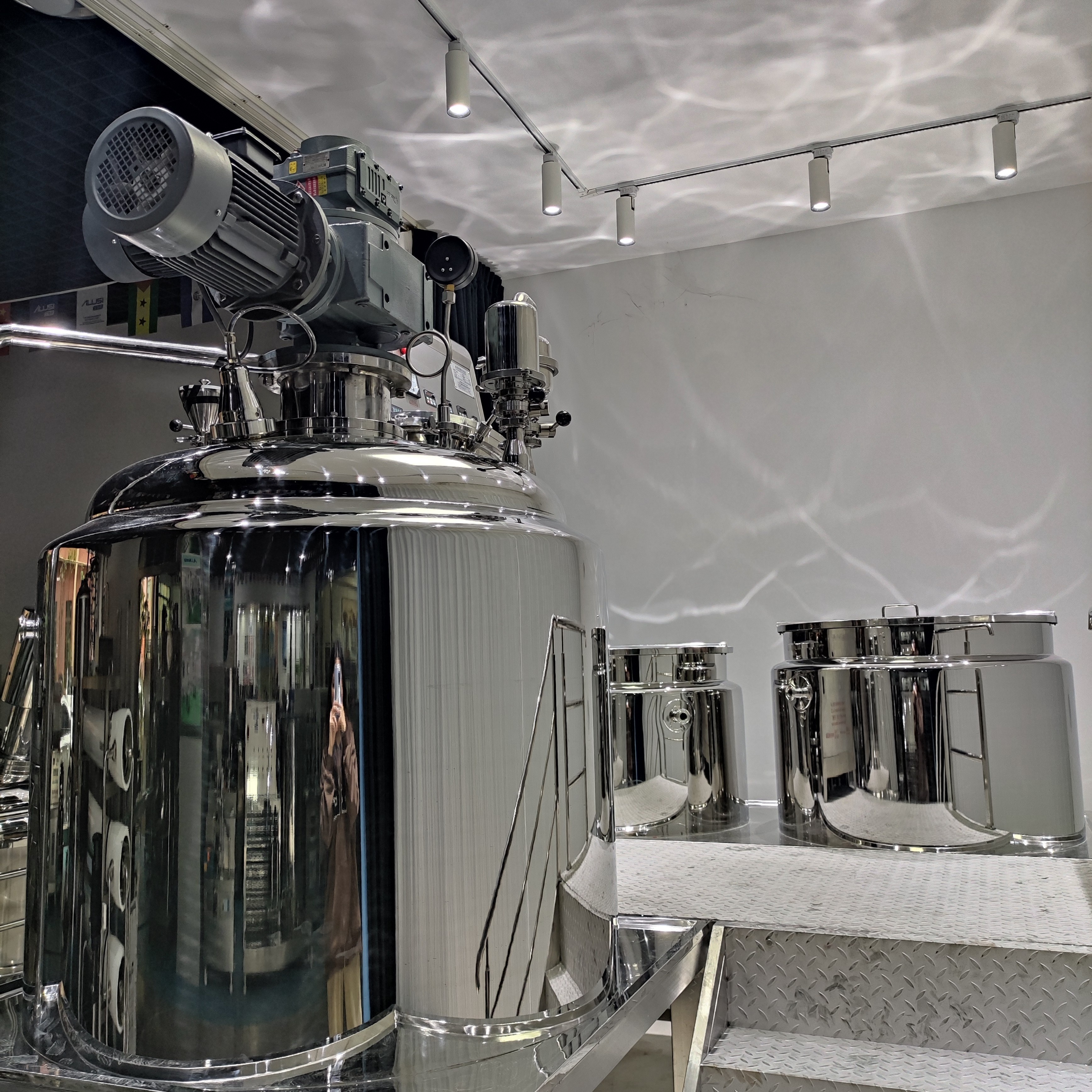

Vacuum emulsifying mixer:

This machine is suitable for the production of various kinds of paste, cream products in cosmetic factory and pharmaceutical factory. Especially designed for the production of stable emulsions creams, milk, gels, balms, lotions, ointments, toothpastes, etc. having extremely small particles for chemical, cosmetics, pharmaceutical and food industries.

Standard configuration

◆ Emulsifier, water phase tanks, oil phase tank

◆ Three-layer tank, steam or electric heating

◆ Vacuum pumps and sync solenoid valves

◆ emulsifier and material filter

◆ 3600rpm high-speed homogenizer, fineness 0.2-5um

◆ mixing system

◆ Stainless steel platform

◆ Inverter and electrical control box

◆ Emulsifier, water phase tanks, oil phase tank

◆ Three-layer tank, steam or electric heating

◆ Vacuum pumps and sync solenoid valves

◆ emulsifier and material filter

◆ 3600rpm high-speed homogenizer, fineness 0.2-5um

◆ mixing system

◆ Stainless steel platform

◆ Inverter and electrical control box

Working Principle

The materials in the water-phase tank and oil-phase tank are heated up and stirred. After they are thoroughly mixed, they will be transferred to the emulsifying tank by vacuum pump. The material will be stirred by the upper part of the central paddle, combined with the PTFE scraper sweeping the wall, the material will be stirred thoroughly and meanwhile be pushed down to the emulsifier at the low part of the central axle. With very high speed emulsifying effect, the material will be seriously cut, sheared, and cracked into 200nm – 2um particles. The bubbles appear during the process will be sucked out promptly in the vacuum status in the tank.

The materials in the water-phase tank and oil-phase tank are heated up and stirred. After they are thoroughly mixed, they will be transferred to the emulsifying tank by vacuum pump. The material will be stirred by the upper part of the central paddle, combined with the PTFE scraper sweeping the wall, the material will be stirred thoroughly and meanwhile be pushed down to the emulsifier at the low part of the central axle. With very high speed emulsifying effect, the material will be seriously cut, sheared, and cracked into 200nm – 2um particles. The bubbles appear during the process will be sucked out promptly in the vacuum status in the tank.

|

Type

|

|

Fixed type

|

|

|

|||

|

Material

|

|

SUS316L for all contact parts and SUS304 for external

|

|

|

|||

|

Mixing

|

|

Siemens motor + reducer

DELTA inverter(Option: Horizontal motor/ABB motor/Ex-proof motor) |

|

|

|||

|

Bottom homogenizer

|

|

0-3600rpm

|

|

|

|||

|

Discharging way

|

|

bottom discharge/Positive pressure discharge

|

|

|

|||

|

Heating Function

|

|

Electric heating/Steam heating/Single Layer(without heating)

|

|

|

|||

Details Images

Lid

Material filter, vacuum pressure meter, vacuum discharge valve, vacuum inlet, positive pressure inlet, CIP system (Spray ball), sight glass light, sight window, man-hole, hopper

Mixer

Frame wall scrapping blender

Stirrer paddle: SUS316L, thick: 12mm

Scraper blade: PTFE material, thick: 15mm, white

Stirrer paddle: SUS316L, thick: 12mm

Scraper blade: PTFE material, thick: 15mm, white

Homogenizer head

Material: SUS316L

Speed: 0-3600rpm(60Hz)

Rotor and stator adopts wire-cutting finish machining, polishing treatment before assembly

Speed: 0-3600rpm(60Hz)

Rotor and stator adopts wire-cutting finish machining, polishing treatment before assembly

Homogenizer head

Material: SUS316L

Speed: 0-3600rpm(60Hz)

Rotor and stator adopts wire-cutting finish machining, polishing treatment before assembly

Speed: 0-3600rpm(60Hz)

Rotor and stator adopts wire-cutting finish machining, polishing treatment before assembly

Inside of tank

Pot: SUS316L

Seal head: SUS316L

Both side welding for seal head & pot, grinding and polishing

Seal head: SUS316L

Both side welding for seal head & pot, grinding and polishing

Water& oil tank

Inside boiler and exposed parts polishing>300mesh

Disperser, SUS316L

Disperser, SUS316L

HMI (option)

touch screen High profile

Control panel

Button: Each function switch control button, Power indicator light, scram etc.

Bottom homogenizer and outlet

homogenizer motor

Discharge hole

Video Show

Specification

Successful Project

Packing & Delivery

Packing

Certifications

Hot Searches