- Product Details

- {{item.text}}

Quick Details

-

Control System Brand:

-

Cypcut

-

Cutting Area:

-

1500*3000mm

-

Cutting Thickness:

-

Depending on the materail

-

Control Software:

-

Cypcut/NC studio

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

LOOKE

-

Weight (KG):

-

3500 KG

-

Core Components:

-

fiber laser

-

Model:

-

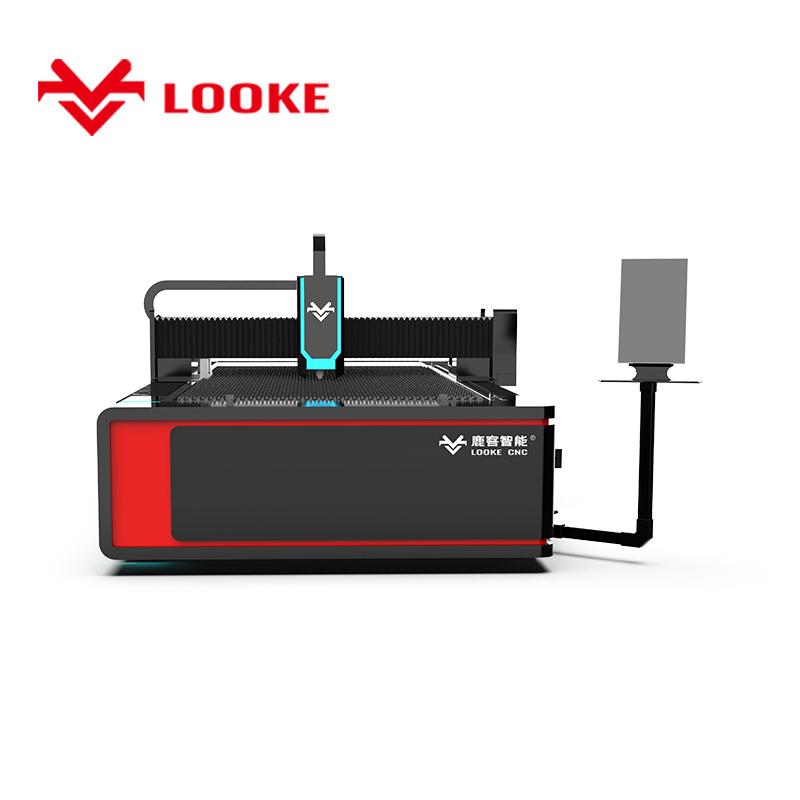

LOOKE-L3015F Fiber laser cutting machine

-

Working area:

-

1500*3000mm working area

-

Laser cutting head:

-

Raytools or WSX laser head

-

Laser source:

-

1000/1500/2000/3000W Raycus/ MAX fiber laser source

-

Bed structure:

-

High rigidity welded steel framework

-

Guide rail:

-

Taiwan Hiwin linear square guide rail 25mm

-

Table surface:

-

Blade table

-

Transmission:

-

X,Y with helical gear rack ,Z with TBI ball screw

-

Motors and drivers:

-

FUJI servo motor & driver, X,Y axis 750w, Z axis 400w

-

Control system:

-

FSCUT 3000S control system

Quick Details

-

Laser Type:

-

Fiber Laser

-

Cutting Speed:

-

Depending on the materail

-

Cooling Mode:

-

WATER COOLING

-

Control System Brand:

-

Cypcut

-

Cutting Area:

-

1500*3000mm

-

Cutting Thickness:

-

Depending on the materail

-

Control Software:

-

Cypcut/NC studio

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

LOOKE

-

Weight (KG):

-

3500 KG

-

Core Components:

-

fiber laser

-

Model:

-

LOOKE-L3015F Fiber laser cutting machine

-

Working area:

-

1500*3000mm working area

-

Laser cutting head:

-

Raytools or WSX laser head

-

Laser source:

-

1000/1500/2000/3000W Raycus/ MAX fiber laser source

-

Bed structure:

-

High rigidity welded steel framework

-

Guide rail:

-

Taiwan Hiwin linear square guide rail 25mm

-

Table surface:

-

Blade table

-

Transmission:

-

X,Y with helical gear rack ,Z with TBI ball screw

-

Motors and drivers:

-

FUJI servo motor & driver, X,Y axis 750w, Z axis 400w

-

Control system:

-

FSCUT 3000S control system

Product Description

3015F 2060F 2040F Widely Used metal steel sheet plate cutter machine CNC laser fiber 12000 watt fiber laser cutting machine

The 4 axis Fiber laser cutting machine adopting world famous Germany fiber laser source and USA laser cutting head and dynamic focus system, it can cut and punch different kinds of metal material with high precision and high speed. Since laser is transmitted by fiber , it is no need to maintenance or adjusts the laser optical path , it greatly reduces the machines fault rate and prolongs the working life. Large format cutting area meets the demands of various kinds of metal processing.

It is widely used for carbon steel, stainless steel, aluminum and other metal materials cutting and forming, with high speed, high precision, high efficiency, cost-effective and energy saving. It is the first choice of the metal processing industry.

This model with the rotary device on the side of the machine, which can be cut the steel tube, pipe.

It is widely used for carbon steel, stainless steel, aluminum and other metal materials cutting and forming, with high speed, high precision, high efficiency, cost-effective and energy saving. It is the first choice of the metal processing industry.

This model with the rotary device on the side of the machine, which can be cut the steel tube, pipe.

LOOKE-L3015 fiber laser metal cutting machine outline dimension wire frame diagram

1. This picture is only used for customer to plan the venue and display the machine.

1. This picture is only used for customer to plan the venue and display the machine.

2. When the machine dimension changed, will let you know.

3. This picture provided by Jinan LOOKE Intelligent Equipment Co.,LTD

3. This picture provided by Jinan LOOKE Intelligent Equipment Co.,LTD

Specification

|

Model

|

LOOKE-L3015F 4 Axis Fiber laser cutting machine

|

|

Working area

|

1500*3000mm working area

|

|

Laser source

|

1000/1500/2000/3000W Raycus/ MAX fiber laser source

|

|

Laser cutting head

|

Raytools or WSX laser head

|

|

Bed structure

|

High rigidity welded steel framework

|

|

Table surface

|

Blade table

|

|

Guide rail

|

Taiwan Hiwin linear square guide rail 25mm

|

|

Transmission

|

X,Y with helical gear rack ,Z with TBI ball screw

|

|

Motors and drivers

|

FUJI servo motor & driver, X,Y axis 750w, Z axis 400w

|

|

Control system

|

FSCUT 3000S control system

|

|

Software

|

TubePro CypCut software

|

|

Chiller

|

S&A, Dual Temperature Control or Hanli brand chiller

|

|

Tube size

|

Length: 6m

Diameter: 200/350mm |

|

Reducer

|

Japan imported SHIMPO reducer

|

|

Tool sensor

|

Automatic tool sensor

|

|

Lubrication system

|

Electric automatic lubrication system

|

|

Pressure valves

|

High-pressure(N2,air):2.5MPa(Shuoda)

Low-pressure(O2):1MPa(SMC)

|

|

Electronic Proportional Valve

|

SMC from Japan

|

|

Electronic Components

|

SCHNERDER, Omron

|

|

Max. idling speed

|

80m/min

|

|

Positioning Accuracy

|

±0.03mm

|

|

Re-Positioning Accuracy

|

±0.02mm

|

|

Instruction format

|

G code *.u00 *.mmg *.plt

|

|

Working voltage

|

AC380V, 3 phase,50-60hz(for more than 1000w)

AC220V, single phase, 50-60hz(for 1000w) |

|

Others

|

Tool box, English Manual, Exhaust fan, cutting nozzle, protection mirrors etc

|

Machine details

Performance feature

1 .Excellent beam quality: Smaller focus diameter , high work efficiency, better processing quality.

2. High cutting speed: 2-3 times faster than YAG and CO2 laser .

3.High Stability: Adopt superior quality fiber laser, stable performance, key parts can reach .

4. High efficiency for photoelectric conversion : Compared with CO2 laser cutting machine, Fiber laser cutting machine has 3 times photoelectric conversion and with energy saving & friendly environment

1 .Excellent beam quality: Smaller focus diameter , high work efficiency, better processing quality.

2. High cutting speed: 2-3 times faster than YAG and CO2 laser .

3.High Stability: Adopt superior quality fiber laser, stable performance, key parts can reach .

4. High efficiency for photoelectric conversion : Compared with CO2 laser cutting machine, Fiber laser cutting machine has 3 times photoelectric conversion and with energy saving & friendly environment

Advantages:

1. Low cost: The whole power consumption is only 20-30% of traditional CO2 laser cutting machine.

2.Low maintenance cost: It is with Optical fiber line transmission, no need reflector lens, can save a lot of maintenance cost.

3.Easy Operation : Fiber Line transmission, no adjustment of optical path.

4.Super-flexible optical effect : small volume, compact structure, easy to flexible manufacturing requirements.

1. Low cost: The whole power consumption is only 20-30% of traditional CO2 laser cutting machine.

2.Low maintenance cost: It is with Optical fiber line transmission, no need reflector lens, can save a lot of maintenance cost.

3.Easy Operation : Fiber Line transmission, no adjustment of optical path.

4.Super-flexible optical effect : small volume, compact structure, easy to flexible manufacturing requirements.

Sample exbition

Packing & Delivery

We will strictly inspection the goods before packing by professional team. Before shipping, they will commission cnc router firstly, then brush oil to linear guide, ball screw, and all the metal sheet,and then lubricate all the hinged parts like pin and bearings. All those wood carving machine will be kept clean,covered of plastic film and then put into the plywood case. Then the cnc router will be in its good conditions on the whole inland and sea transportation. When the machine arrives, a nice,safe,strong and beautiful packaging will catch the client's eyes unexpectedly.

Hot Searches