- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Filter Rating:

-

90-99%

-

Thickness:

-

4~12mm

-

Length:

-

10mm-6m

-

Width:

-

0.75,1.50,1.80,2.30,3.00,3.30,3.70 ,etc.

-

Usage:

-

Separator, Lithium Battery, Chemical And Petroleum

-

Shape:

-

Cylindrical

-

Slot:

-

100micron, 200 micron, 500micron etc

-

Keywords:

-

Spare Parts For Water treatment

-

Function:

-

Solid Liquid,Gas Separation

Quick Details

-

Weight (KG):

-

1

-

Marketing Type:

-

Wedge Sintered Wire Mesh Screen

-

Core Components:

-

Filter, Wedge Wire Screen

-

Place of Origin:

-

Jiangsu, China

-

Filter Rating:

-

90-99%

-

Thickness:

-

4~12mm

-

Length:

-

10mm-6m

-

Width:

-

0.75,1.50,1.80,2.30,3.00,3.30,3.70 ,etc.

-

Usage:

-

Separator, Lithium Battery, Chemical And Petroleum

-

Shape:

-

Cylindrical

-

Slot:

-

100micron, 200 micron, 500micron etc

-

Keywords:

-

Spare Parts For Water treatment

-

Function:

-

Solid Liquid,Gas Separation

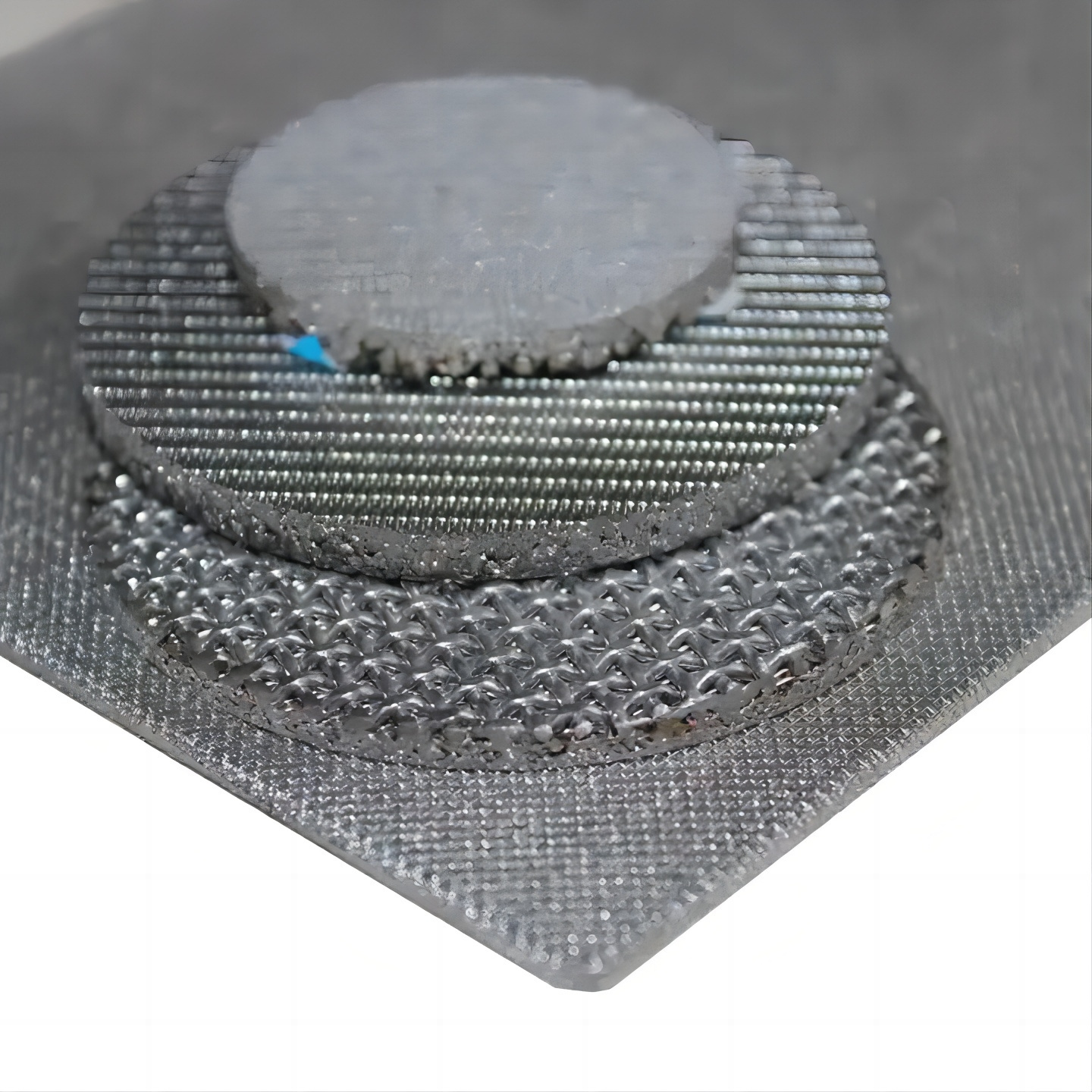

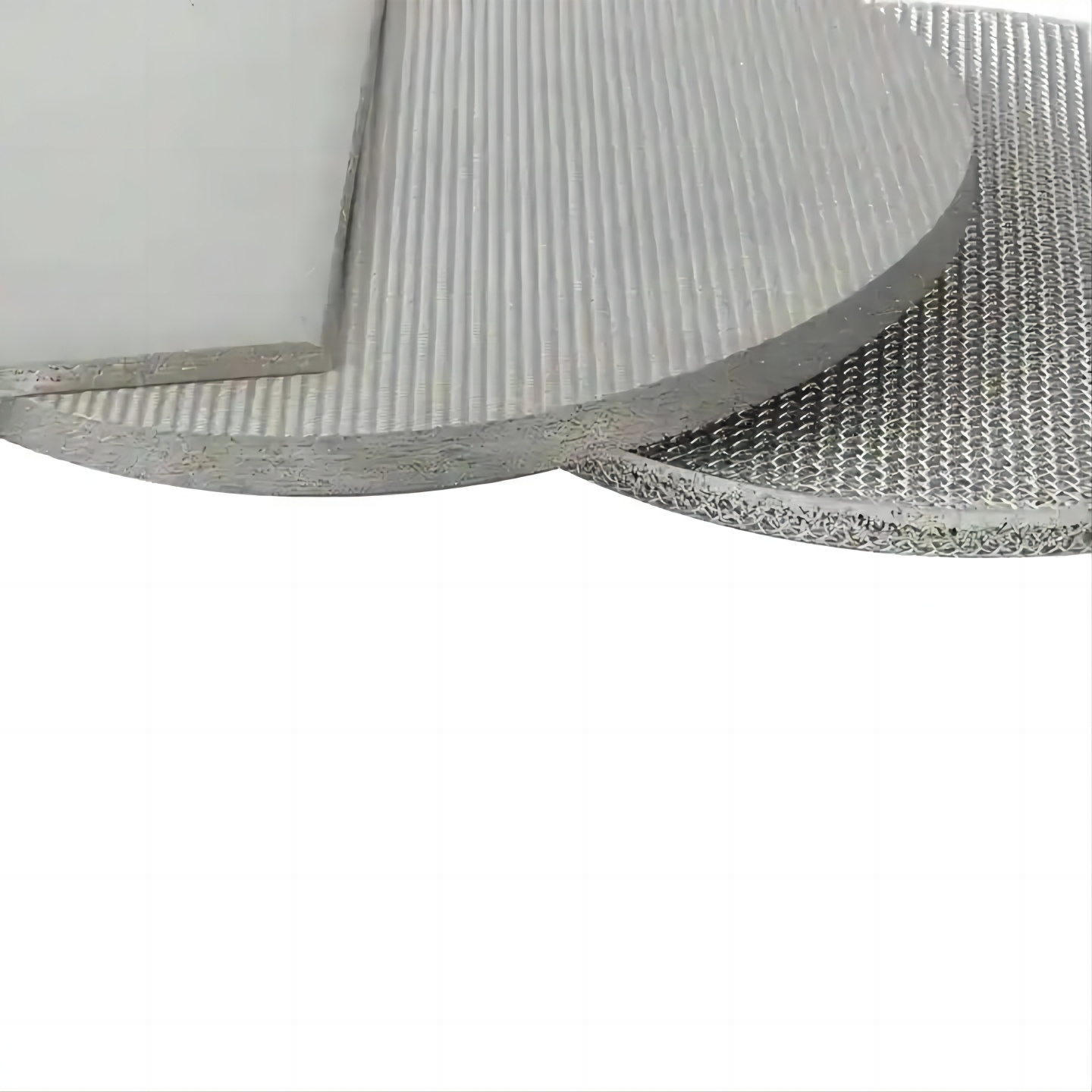

Wedge Sintered Wire Mesh Screen

Structural Principle:

The metal sintered mesh filter cartridge is mainly made of standard four-layer or five-layer sintered mesh with stainless steel wire overlaid and vacuum sintered.

Product introduction:

It features strong corrosion resistance, good permeability, high strength, accurate filtration precision, hygienic and clean

filter media, and no wire shedding.

The metal sintered mesh filter cartridge is mainly made of standard four-layer or five-layer sintered mesh with stainless steel wire overlaid and vacuum sintered.

Product introduction:

It features strong corrosion resistance, good permeability, high strength, accurate filtration precision, hygienic and clean

filter media, and no wire shedding.

Product Details

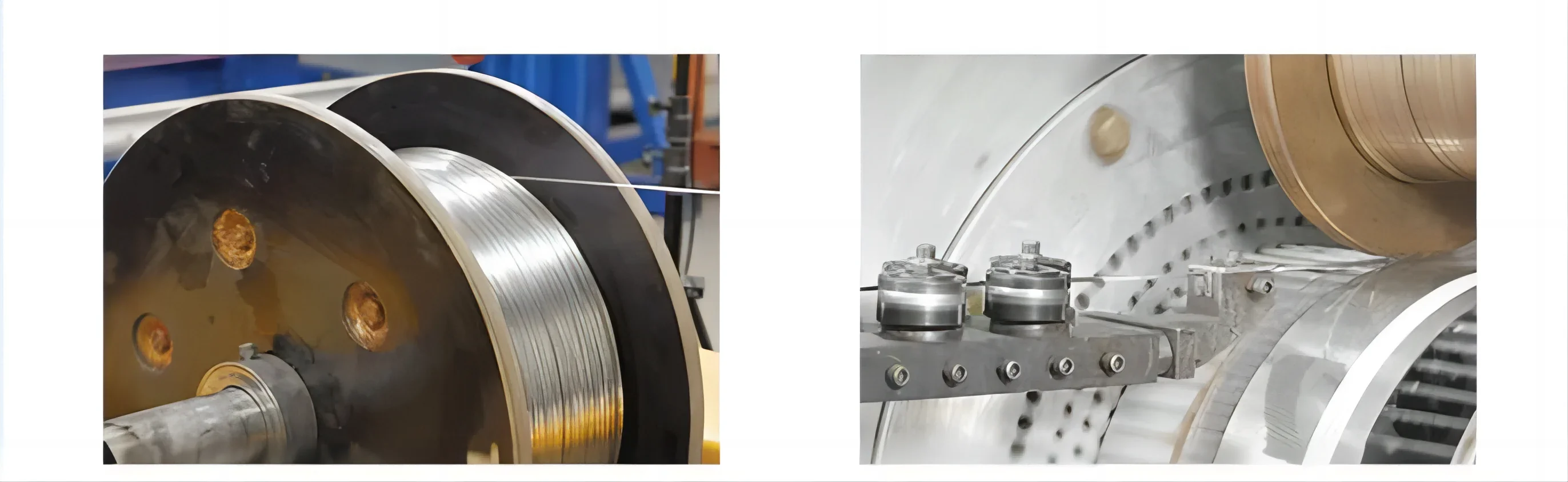

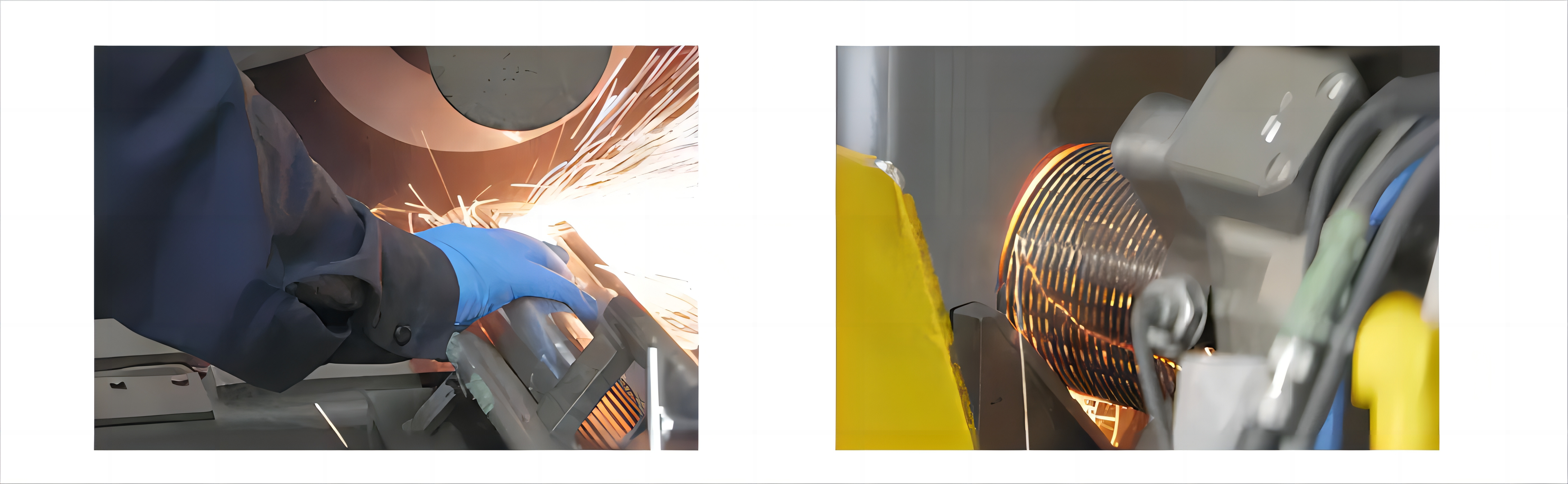

What is wedge-wire and how it's made

Wedge wire screens are manufactured by resistance welding V-shaped wire on support rods. Our wedge wire screen begins with the highest quality raw wire then is made into screen that is cut, shaped, fabricated and cleaned. Wedge wire can be ordered as raw screen material or fabricated to a finished product to suit your application requirements. The pin point control over the specifications of the slot is what allows Screen to provide its customers with highly accurate flow distribution and effective media, debris and sediment filtration. Support Rods running perpendicular to the wrap wire strengthen and maintain the proper design configuration of the screen allowing it to handle intense pressure demands.

Our Wedge Wire Screen is designed to control various processing conditions including volumetric flow rate, minimum dimensional media retention, minimum open area and fluid pressure capabilities. Screen is able to professionally work a large variety of stainless steels and alloys into both standard or customized screen applications and accessory products.

Our screen can be welded to nipples, couplings, pipe, or flanges. The fabricated and welded construction makes for durable quality vessel internals and media retention products. Wire mesh and perforated pipe may be less expensive initially, but wedge wire screens offer easier installation and long-term operating and cost benefits.

Our screen can be welded to nipples, couplings, pipe, or flanges. The fabricated and welded construction makes for durable quality vessel internals and media retention products. Wire mesh and perforated pipe may be less expensive initially, but wedge wire screens offer easier installation and long-term operating and cost benefits.

Screens are available in slot sizes ranging from 0.001 in. (25μm) up to (1/2").

Many different variations of wire and rod sizes/profiles can be selected to develop the exact screen of your choice.Any process or vessel requirements can be accommodated, such as vertical or horizontal vessels.

The most common material of construction is 300 series stainless steel, however many exotic alloys are available upon request such as SS321, SS304,SS316L,TA2,Duplex SS, Alloy 20,Copper Nickel, Hastelloy C-276, Alloy B-3, Monel 400.

Screen diameters range from 0.750 in. to 38" in size straight from our machines. Screen can be fabricated in upwards to 52" O.D in two or more sections depending on the requirements. Screens also are made in various different configurations, including cylindrical, flat, specialty shapes or curved.

Many different variations of wire and rod sizes/profiles can be selected to develop the exact screen of your choice.Any process or vessel requirements can be accommodated, such as vertical or horizontal vessels.

Drawing

Customizable according to customer size requirements.

Specification

Hanpu Surface Wire Specifications:

|

Name

|

Breadth

|

Altitude

|

α°

|

Cross-sectional area -Q

|

Resistance moment -W

|

Bending moment - |

|

|

|

mm

|

mm

|

|

mm2

|

mm3

|

mm4

|

|

0.8

|

0.8(round)

|

-

|

-

|

0.5

|

0.05

|

0.02

|

|

⊘1

|

1 (round)

|

-

|

-

|

0.785

|

0.098

|

0.049

|

|

⊘2

|

2(round)

|

-

|

-

|

3.14

|

0.785

|

0.785

|

|

4S

|

0.45

|

1.2

|

6

|

0.4003

|

0.0848

|

0.0442

|

|

5S

|

0.5

|

1.25

|

6

|

0.4760

|

0.1026

|

0.0566

|

|

6SC

|

0.6

|

1.2

|

13

|

0.5

|

0.071

|

0.051

|

|

10S

|

0.75

|

1.425

|

10

|

0.728

|

0.13

|

0.109

|

|

11S

|

0.75

|

1.8

|

8

|

0.912

|

0.208

|

0.22

|

|

12S

|

1

|

2

|

10

|

1.32

|

0.327

|

0.388

|

|

12SL

|

1

|

2

|

-

|

1.104

|

0.204

|

0.204

|

|

15S

|

1.2

|

2.5

|

10

|

1.97

|

0.605

|

0.899

|

Hanpu Surface Wire Specifications:

|

Name

|

Breadth

|

Altitude

|

Cross-sectional area -Q

|

Resistance moment -W

|

Bending moment - |

|

|

|

mm

|

mm

|

mm2

|

mm3

|

mm4

|

|

Q22

|

2

|

2.28

|

3.273

|

1.005

|

0.892

|

|

Q25

|

2

|

3

|

4.61

|

2.019

|

2.39

|

|

Q35

|

3

|

5

|

11.75

|

8.52

|

17.032

|

|

Q53

|

5

|

3

|

8.084

|

4.039

|

3.787

|

|

D 45

|

3.8

|

5.6

|

13.803

|

9.67

|

22.512

|

|

D 56

|

5

|

6.5

|

22.14

|

17.678

|

50.031

|

|

10x3

|

3

|

10

|

26.125

|

40.329

|

177.916

|

|

11x5

|

5

|

11

|

42.92

|

62.96

|

299.7

|

|

12x3

|

3

|

12

|

32.02

|

48.848

|

322.14

|

|

15x3

|

3

|

15

|

41.13

|

81.96

|

664.6

|

|

25x3

|

3

|

25

|

71.125

|

283.52

|

664.6

|

Application

Advantages

1.Unobstructed

The V-shaped sieve bars form wedge-shaped gaps to ensure they do not clog.

2.Large open area

With various specifications of V-shaped wire diameters for selection. High water flow efficiency.

3.Easy to clean

Surface debris can be removed using a scraper or steel brush and other back flush methods.

4.Low pressure loss

High mechanical performance, wear resistance.

5.High-precision sieve slots

5.High-precision sieve slots

Automatic welding ensures uniform sieve slot accuracy.

Company Introduction

Processing equipment

Exhibition

Contact me

Hot Searches