Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

Screw Speed (rpm):

-

90 rpm

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

HYD

-

Voltage:

-

380V,50Hz or Customized

-

Dimension(L*W*H):

-

Customized

-

Power (kW):

-

45

-

Weight:

-

36000 KG

-

Product Type:

-

Plastic pipe production line

-

Raw material:

-

Raw material+additatives

-

Automatic Grade:

-

High Automation

-

Color:

-

Customers' Require

-

Motor:

-

Siemens Beide

-

Inverter:

-

ABB Brand

-

Temperature control:

-

Omron Brand

-

Screw type:

-

Singe Screw

-

Product:

-

HDPE PE PP PPR PC PMMA Pipe

-

After-sales Service Provided:

-

Video Technical Support

Quick Details

-

Screw Design:

-

Single-screw

-

Screw L/D Ratio:

-

Other

-

Screw diameter (mm):

-

Other

-

Screw Speed (rpm):

-

90 rpm

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

HYD

-

Voltage:

-

380V,50Hz or Customized

-

Dimension(L*W*H):

-

Customized

-

Power (kW):

-

45

-

Weight:

-

36000 KG

-

Product Type:

-

Plastic pipe production line

-

Raw material:

-

Raw material+additatives

-

Automatic Grade:

-

High Automation

-

Color:

-

Customers' Require

-

Motor:

-

Siemens Beide

-

Inverter:

-

ABB Brand

-

Temperature control:

-

Omron Brand

-

Screw type:

-

Singe Screw

-

Product:

-

HDPE PE PP PPR PC PMMA Pipe

-

After-sales Service Provided:

-

Video Technical Support

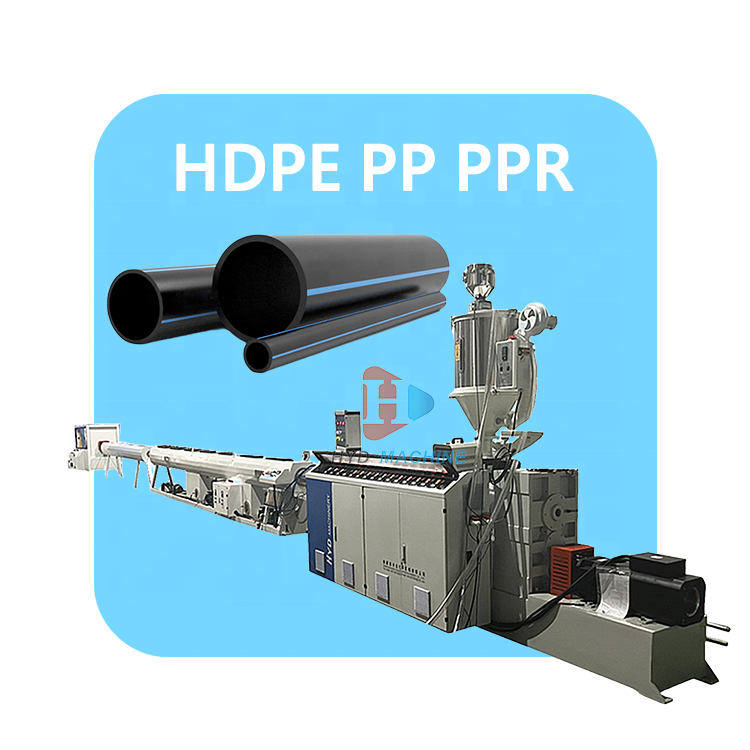

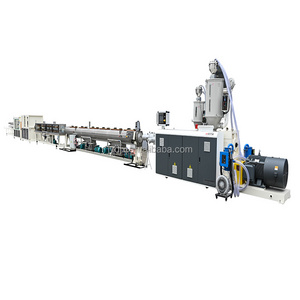

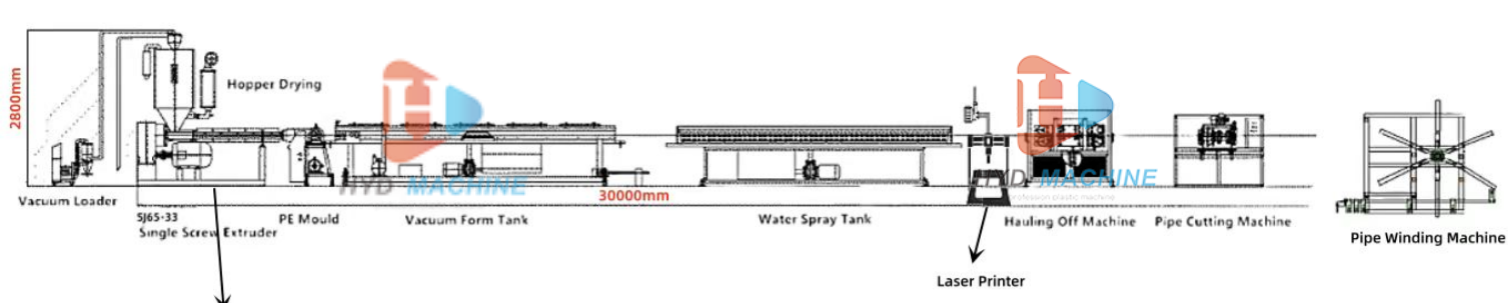

Products Description

This machine is mainly used to produce Single or multi layer

PE/HDPE/PP/PPR

pipe,use for drainage, electricity etc. The machine adopts PLC control, which is easy to operate, stable in operation, high in production efficiency, long in service life and low in noise.

We have several machine models to choose from and also support special customization. Pipe diameter range 20-630 mm

|

Mum

|

Machine

|

Num

|

|

1

|

1st Single Screw Extruder

|

1

|

|

2

|

2nd Single Screw Extruder (

option

)

|

1

|

|

3

|

Color mark line extruder (

option

)

|

1

|

|

4

|

Pipe Mold

|

1

|

|

5

|

Vacuum Form Water Tank

|

1

|

|

6

|

Water Cooling Spray Tank (

option

)

|

1

|

|

7

|

Laser Printer (

option

)

|

1

|

|

8

|

Hauling Off Machine

|

1

|

|

9

|

Pipe Cutting Machine

|

1

|

|

10

|

Stacker (

option

)

|

1

|

|

11

|

Pipe Winding Machine (

option

)

|

1

|

|

12

|

Pipe Belling Machine (

option

)

|

1

|

Details Images

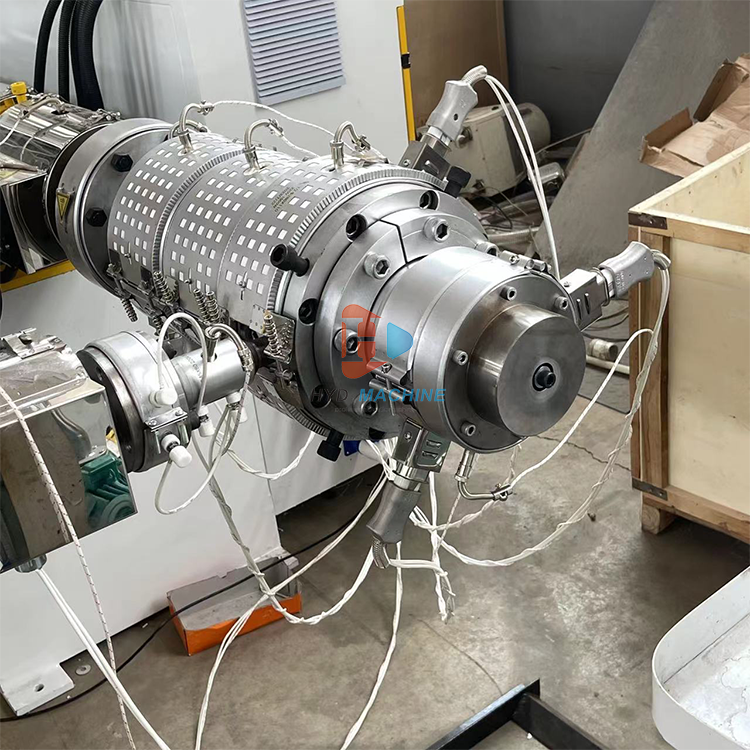

Single Screw Extruder

The raw material is pre-dried, melted in the screw and then extruded

Extrusion Mold

The raw material after melting is preliminarily formed by the mold

Color Mark Line Co-extruder

Use for extrude the color line on the surface of the pipe

Vacuum Form Water Tank

The preliminary pipe is further vacuumed and shaped to make its surface smooth and its size meet the expected requirements

and perform preliminary water cooling of the pipe

Water Cooling Spray Tank

Further cooling of the pipe to reduce the pipe temperature

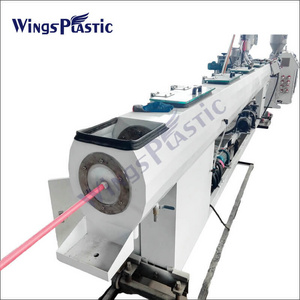

Laser Printer

Can print the company's name, contact phone number, pipe size wall thickness and other information on the surface of the pipe

Hauling Off Machine

Treat the pipes backwards to ensure that the production line continues to run and run

Cutting Machine

Cut the pipe according to the set size

Stacker

Collect and stack finished pipe

Pipe Winding Machine

Use for winding small size pipe, and the machine model size can be customized

Final product reference

FAQ

Q:Are you machinery factory or trading company?

A:We have our own factory,which means we can strictly guarantee product quality and lead time.

Q:If we have very special request for the production line,could you help me to do the design?

A:Experienced mechanical designer customized-design provided.

Q: Do you provide material testing service?

A:We have our own factory,which means we can strictly guarantee product quality and lead time.

Q:If we have very special request for the production line,could you help me to do the design?

A:Experienced mechanical designer customized-design provided.

Q: Do you provide material testing service?

A: Yes, we offer testing service on our machine. An additional testing fee will be charged depends on the testing costs(electricity, labor), however, if you eventually made a purchase with us ,the testing fee will

counts to deduction of machine purchase cost.

Q: How can I make sure the machine running good in my plants?

counts to deduction of machine purchase cost.

Q: How can I make sure the machine running good in my plants?

A: First we will have a home commissioning in our factory for your inspection. If you need assistance in installing and staff training , we can also send engineers to service overseas and solve all problems. (notice: return flight and $80 per day salary will be on customer)

Q: How to get a quote efficiently?

Q: How to get a quote efficiently?

A: Please kindly click on ' Sent An Inquiry ' Button at the bottom of page,or click "Chat now" on the right side of the page. Leave a message to describe details of your final products ( better with a picture and size drawing), Capacity requirements, We will reply to your inquiry within 12 hours

Q: How can we visit your company and machines?

A : Our factory is in Jinfeng Town, Zhangjiagang City, Jiangsu Province, China. Close to Shanghai, about 1 hour by high-speed train

Q:What`s the payment method?

A: T/T, L/C,Western Union,etc

Q: How can we visit your company and machines?

A : Our factory is in Jinfeng Town, Zhangjiagang City, Jiangsu Province, China. Close to Shanghai, about 1 hour by high-speed train

Q:What`s the payment method?

A: T/T, L/C,Western Union,etc

Hot Searches