- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Shine East

-

Voltage:

-

380V/220V/440V

-

Dimension(L*W*H):

-

6m*4m*2m

-

Power (kW):

-

20

-

Weight:

-

1000 KG

-

Raw material:

-

PVC/PU/TPU

-

After-sales Service Provided:

-

Online

-

After Warranty Service:

-

Video technical support

-

Marketing Type:

-

New Product 2022

Quick Details

-

Screw Design:

-

Single-screw

-

Screw L/D Ratio:

-

30:1

-

Screw Speed (rpm):

-

60 rpm

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Shine East

-

Voltage:

-

380V/220V/440V

-

Dimension(L*W*H):

-

6m*4m*2m

-

Power (kW):

-

20

-

Weight:

-

1000 KG

-

Raw material:

-

PVC/PU/TPU

-

After-sales Service Provided:

-

Online

-

After Warranty Service:

-

Video technical support

-

Marketing Type:

-

New Product 2022

Products Description

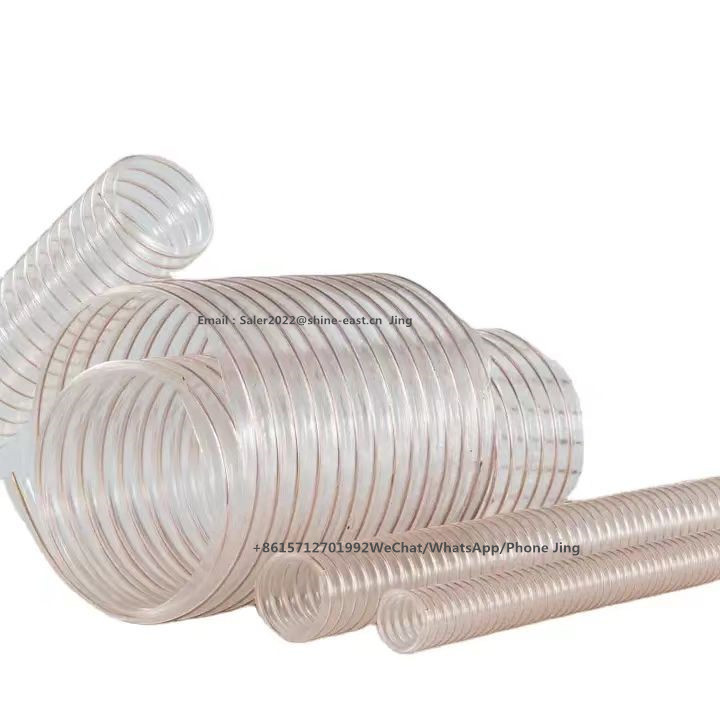

Description----Helix Suction pipe Hose production line

The Helix Suction pipe Hose production line is mainly composed of two extruders, spiral forming unit, water cooling tank, hauloff, coiler etc.

This hose is also called PVC suction hose, which takes the advantages of extrusion resistance, corrosion resistance, negative pressure resistance, anti-bending, good liquidity.

So it is suitable to convey gas, liquid and powder, widely used in industry, agriculture, constructionn and irrigation, etc.

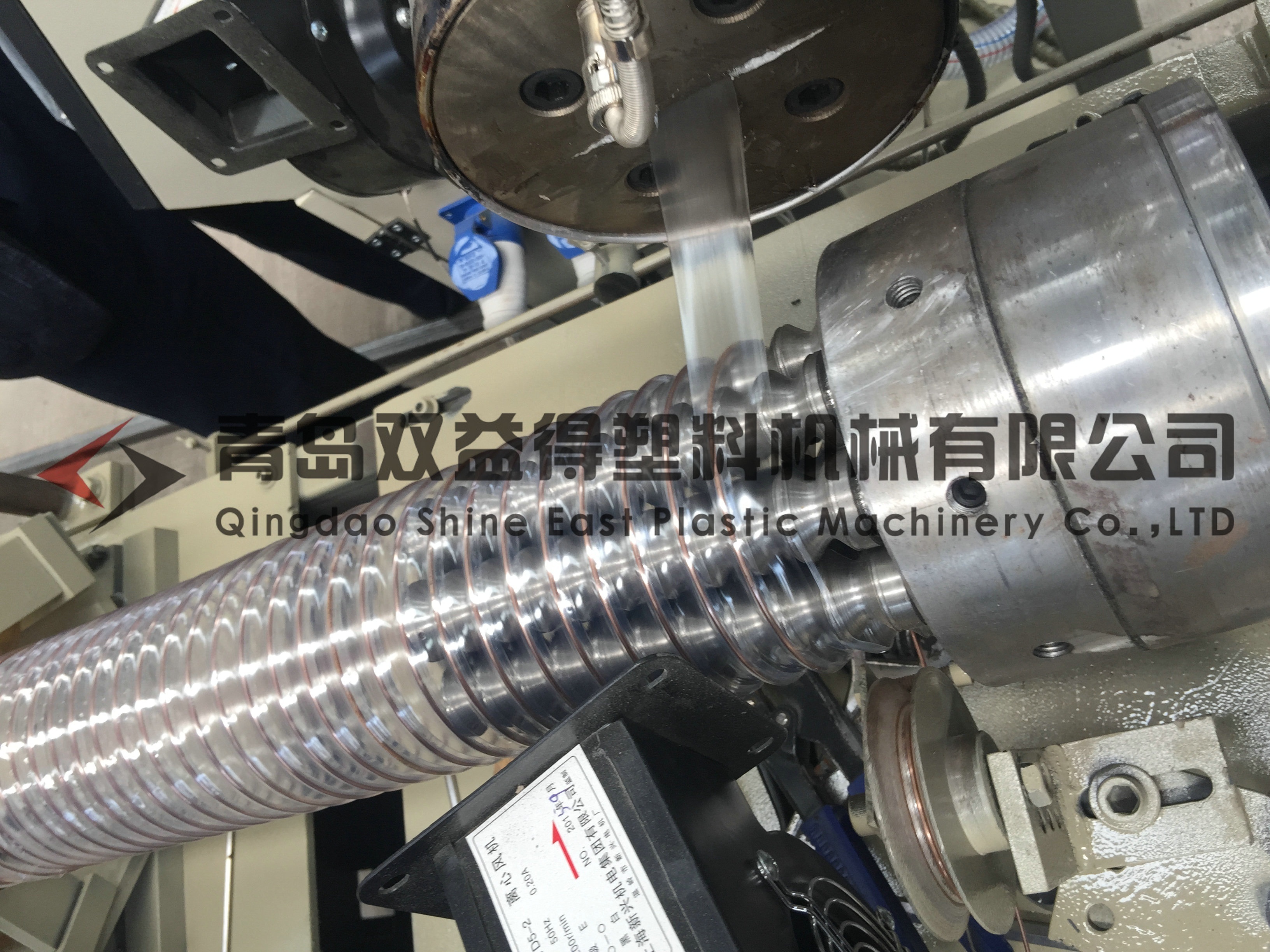

Working process--- Helix Suction pipe Hose production line

The Helix Suction pipe Hose production line is mainly composed of two extruders, spiral forming unit, water cooling tank, hauloff, coiler etc.

This hose is also called PVC suction hose, which takes the advantages of extrusion resistance, corrosion resistance, negative pressure resistance, anti-bending, good liquidity.

So it is suitable to convey gas, liquid and powder, widely used in industry, agriculture, constructionn and irrigation, etc.

Working process--- Helix Suction pipe Hose production line

Raw material+additive→Mixing→Granulating→Conveying feeding→Single screw extruder→Steel wire forming machine→Extruding mould→Spray cooling water tank→Belt haul-off→Winder→packing

Usage:

abrasive solids such as dust , powders, fibers , chips , and particulate matter ;

Gaseous medium , such as oil vapors and welding smoke ;

Industrial dust and suction , particle objects conveyor systems, printing machines , blowers and compressors ;

As a robust anti-wear protection tube ;

Road sweepers, lawn mowers, lawn mowers and leaf collecting emissions ;

abrasive solids such as dust , powders, fibers , chips , and particulate matter ;

Gaseous medium , such as oil vapors and welding smoke ;

Industrial dust and suction , particle objects conveyor systems, printing machines , blowers and compressors ;

As a robust anti-wear protection tube ;

Road sweepers, lawn mowers, lawn mowers and leaf collecting emissions ;

Product Specifications

|

Items

|

Description

|

set

|

Function

|

set

|

|||

|

1

|

Single screw extruder

|

1

|

Extrude initial shape of hose

|

1

|

|||

|

2

|

Die head and mould

|

1

|

130 kw

|

1

|

|||

|

3

|

Winding forming unit

|

1

|

Drive the forming moulds

|

1

|

|||

|

4

|

Forming mould

|

1

|

Form the initial shape of hose shape

|

Depend on diameter of hose

|

|||

|

5

|

Cooling system

|

1

|

Down temperature of the hose

|

1

|

|||

|

6

|

Haul off system

|

1

|

Forward hose moving

|

1

|

|||

|

7

|

Electric controlling system

|

1

|

Controlling the whole line

|

1

|

|||

|

8

|

Other information please contact us , we will provide you full solution

|

|

|

|

|||

We specialized in making all kinds of soft , flexible and spiral and different of plastic hose making machinery .

Include :

cable protection corrugation hose machine

cable protection spiral hose machine

vacuum cleaner spiral hose(eva material ) machine

swimming pool cleaning hose machine

water exhaust hose machine

air exhaust hose machine

industrial use spiral hose machine

medical use hose machine

siphon hose machine

water drainage hose machine

air conditioning drainage hose machine

washing machine hose making machine

metal spiral hose machine

plastic spiral hose machine

smoking hookah hose making machine

Include :

cable protection corrugation hose machine

cable protection spiral hose machine

vacuum cleaner spiral hose(eva material ) machine

swimming pool cleaning hose machine

water exhaust hose machine

air exhaust hose machine

industrial use spiral hose machine

medical use hose machine

siphon hose machine

water drainage hose machine

air conditioning drainage hose machine

washing machine hose making machine

metal spiral hose machine

plastic spiral hose machine

smoking hookah hose making machine

Single screw extruder

High production capacity of extrusion on the high quality basis. Lower temperature plasticizing design, ensure high quality pipe extrusion. Material of screw and barrel: 38CrMoAlA, nitrogen quenched (0.4-0.7mm ), Rigidity of screw: >740 , Rigidity ofbarel>940, the surface of screw is chrome plated Feeding bush with water cooling system

Die head

Extrusion die adopts 40Cr materials. The surface has special treatment to ensure it is fluent extrusion

Forming Mold1

Alloy steel material to make bright pipe surface(

you can choose)

Forming Mold 2

Water trough

To make sure the machine can normally run.

Copper feeder

Feeding the copper

FAQ

Hot Searches