- Product Details

- {{item.text}}

Quick Details

-

Brick size:

-

400*100*200 mm, 400*120*200 mm, 200*100*60 mm, 300*150*100 mm, 400*150*200 mm, 240*115*90 mm, 200*200*60 mm, 150*150*100 mm, 400*200*200 mm, 230*220*115 mm

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

HF

-

Voltage:

-

Local Voltage

-

Dimension(L*W*H):

-

5120x1950x2810mm

-

Weight (KG):

-

5500 kg

-

Molding cycle:

-

15-20s

-

Pallet size:

-

1100x550mm

-

Rated pressure:

-

16Mpa

-

Vibration frequency:

-

2800-4200r/min

-

Exciting force:

-

65-80KN

-

Raw material:

-

GB steel and Manganese steel

-

Control Method:

-

PLC control Unit

-

Vibration motor:

-

15kwx2sets

-

After Warranty Service:

-

Video technical support

-

Certification:

-

CE/ISO9001

Quick Details

-

Type:

-

Hollow Block Making Machine, Paving Block Making Machine, Interlock Block Making Machine, Curbstone Block Machine, EPS block

-

Brick Raw Material:

-

CONCRETE

-

Production Capacity (Pieces/8 hours):

-

900-1200pcs 400x200x200/hour

-

Brick size:

-

400*100*200 mm, 400*120*200 mm, 200*100*60 mm, 300*150*100 mm, 400*150*200 mm, 240*115*90 mm, 200*200*60 mm, 150*150*100 mm, 400*200*200 mm, 230*220*115 mm

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

HF

-

Voltage:

-

Local Voltage

-

Dimension(L*W*H):

-

5120x1950x2810mm

-

Weight (KG):

-

5500 kg

-

Molding cycle:

-

15-20s

-

Pallet size:

-

1100x550mm

-

Rated pressure:

-

16Mpa

-

Vibration frequency:

-

2800-4200r/min

-

Exciting force:

-

65-80KN

-

Raw material:

-

GB steel and Manganese steel

-

Control Method:

-

PLC control Unit

-

Vibration motor:

-

15kwx2sets

-

After Warranty Service:

-

Video technical support

-

Certification:

-

CE/ISO9001

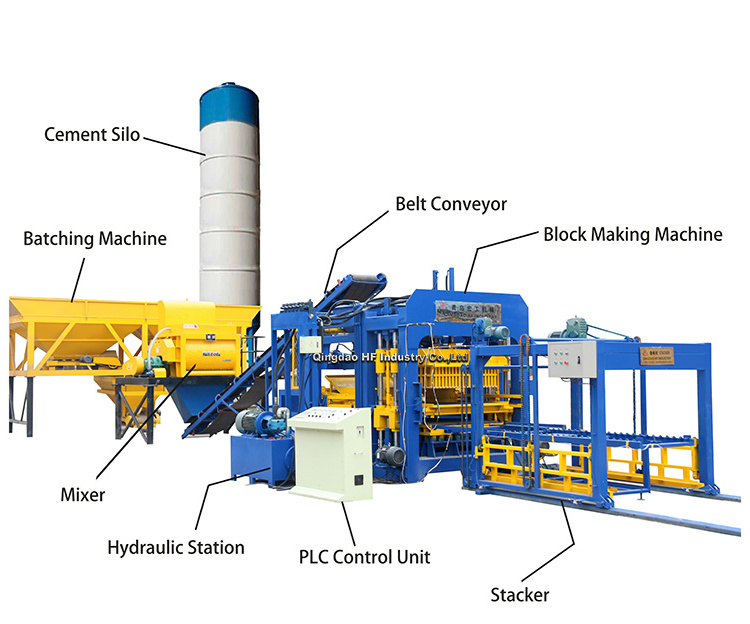

Production Description

QT5-15 automatic Block Making Machine

1. Particular storage and description material system insure the feeding accuracy and avoiding the effect of exterior material. So the products have high density.

2. Adopting synchronization vibration insures the products making average. The frequency can change according to different technics. Low frequency in feeding material, high frequency vibration makes the different material to have a optimal vibration way.

3. The computer is of fault diagnosis system. Warning signal is propitious to eliminate the fault. Combine with long-distance controlling system, it can achieve scrutiny, controlling, diagnosis

4. PLC intelligent control: Man-machine interface, control system equipped with complete logic control, production program, malfunction diagnosis system and remote control function. So it doesn’t need a professional person but only need a simple training to the operator.

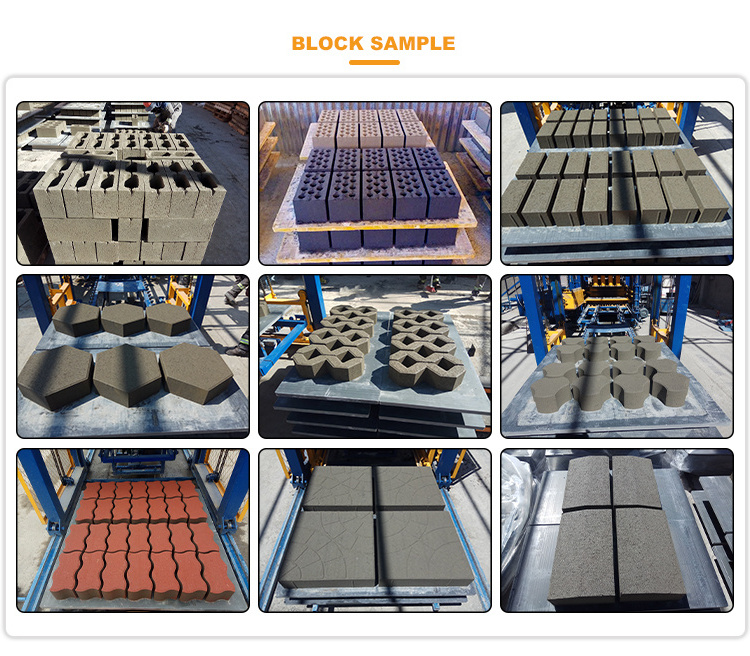

5. It produces various bricks/blocks including color-face bricks (layered material feeding),through-body tiles,lock linkage

blocks, road curb bricks, hydraulic blocks,hollow blocks, perforated bricks, and standard bricks etc.

1. Particular storage and description material system insure the feeding accuracy and avoiding the effect of exterior material. So the products have high density.

2. Adopting synchronization vibration insures the products making average. The frequency can change according to different technics. Low frequency in feeding material, high frequency vibration makes the different material to have a optimal vibration way.

3. The computer is of fault diagnosis system. Warning signal is propitious to eliminate the fault. Combine with long-distance controlling system, it can achieve scrutiny, controlling, diagnosis

4. PLC intelligent control: Man-machine interface, control system equipped with complete logic control, production program, malfunction diagnosis system and remote control function. So it doesn’t need a professional person but only need a simple training to the operator.

5. It produces various bricks/blocks including color-face bricks (layered material feeding),through-body tiles,lock linkage

blocks, road curb bricks, hydraulic blocks,hollow blocks, perforated bricks, and standard bricks etc.

Main Technical Parameter

|

Qty/mould

|

5pcs/mould (hollow block 400*200*200mm)

|

|

Molding cycle

|

15s

|

|

Rated pressure

|

16MPa

|

|

Main vibration

|

Platform vibration

|

|

Vibration frequency

|

2800-4500 r/m

|

|

Power

|

26.5kw

|

|

Pallet size

|

1100x550mm

|

|

Dimension

|

6500x2350x2950mm

|

|

Host machine weight

|

7500kg

|

|

Factory Area

|

3000m²

|

Product Advantages

1. PLC control System; we select original Siemens PLC combine with independently develop machinecontrol program , assure stable and high-efficiency workingstatus.

2. Switches and motor: Adopt Japan Omron and France schneider brand ,

3. motor : we will use Siemens or ABB brand .

4. Hydraulic system : Double proportional hydraulic valve for smooth operation and long service life

5. Mould: Mnaganese steeel, deal with advanced heat treatment device assure longer mould life. and carburizing treatment will assure longer mould life span and ensure the strength of mould reach to 54-58HRC so that the mould can be used more than 100 thousand times.

6. Spare parts: follow the machine to shipment, we supply suitable wearing parts ,the after-sale services will be faster.

2. Switches and motor: Adopt Japan Omron and France schneider brand ,

3. motor : we will use Siemens or ABB brand .

4. Hydraulic system : Double proportional hydraulic valve for smooth operation and long service life

5. Mould: Mnaganese steeel, deal with advanced heat treatment device assure longer mould life. and carburizing treatment will assure longer mould life span and ensure the strength of mould reach to 54-58HRC so that the mould can be used more than 100 thousand times.

6. Spare parts: follow the machine to shipment, we supply suitable wearing parts ,the after-sale services will be faster.

Block Sample

Related Products

Our Customer

Hot Searches