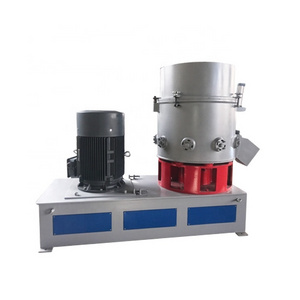

GHX high speed granulator makes disposed plastic films and materials with less than 2mm wall thickness materials into granules. When the waste plastic is supplied into the chamber of such machine, it will be cut into smaller chips due to the crushing function of the rotating knife and fixed knife. During the crushing processing, the material that soaked up lots heat from the frictional movement of material being crushing and the wall of container will be going to become semi-plasticizing state. The particles will stick with each other due to the function of plasticization. Before it sticks each other completely, the cold water pre-prepared is sprayed into the material being crushed. The water will be evaporated off quickly and the surface temperature of material being crushed drop down quickly also. So the material being crushed will become small particles or granules. It is easy to recognize the particles by different size and can be colored by using of color agent being putted into the container during the crushing processing.

- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V/customized

-

Dimension(L*W*H):

-

2200*1300*1600 mm

-

Power (kW):

-

30-132

-

Weight:

-

5000

-

Inner layer material:

-

Stainless steel 304

-

Water consumption:

-

15L/H

-

Bearing Brand:

-

LYC Brand

-

Rotation speed:

-

800RPM

-

Rotation Blade QTY:

-

6PCS

-

Fixed Blade QTY:

-

2PCS

-

Discharging model:

-

pneumatic

-

Electrical elements:

-

DELIXI Brand

-

Electrical box size:

-

650*300*135

-

Color:

-

Customized Color

Quick Details

-

Output (kg/h):

-

50 - 700 kg/h

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

SPIRE

-

Voltage:

-

380V/customized

-

Dimension(L*W*H):

-

2200*1300*1600 mm

-

Power (kW):

-

30-132

-

Weight:

-

5000

-

Inner layer material:

-

Stainless steel 304

-

Water consumption:

-

15L/H

-

Bearing Brand:

-

LYC Brand

-

Rotation speed:

-

800RPM

-

Rotation Blade QTY:

-

6PCS

-

Fixed Blade QTY:

-

2PCS

-

Discharging model:

-

pneumatic

-

Electrical elements:

-

DELIXI Brand

-

Electrical box size:

-

650*300*135

-

Color:

-

Customized Color

Product Description

plastic agglomerator machine

Effect Picture

It is suitable for soft PVC, HDPE, LDPE, soft PE, PS, PP and other thermoplastic wastes and films and froth PS wastes.

More details

Specification

|

Model

|

Volume(L)

|

Motor power(KW)

|

Capacity(KG/HR)

|

Rotation speed

|

|

SPR-100

|

100L

|

30KW

|

50-100KG/HR

|

800RPM

|

|

SPR-200

|

200L

|

45KW

|

100-200KG/HR

|

800RPM

|

|

SPR-300

|

300L

|

75KW

|

200-300KG/HR

|

800RPM

|

|

SPR-400

|

400L

|

90KW

|

300-400KG/HR

|

800RPM

|

|

SPR-500

|

500L

|

110KW

|

400-500KG/HR

|

800RPM

|

|

SPR-800

|

600L

|

132KW

|

600-700KG/HR

|

800RPM

|

Packing & Delivery

Wooden box package

Sea transportation

Carrie XU WhatsApp:+861855124761

Hot Searches