- Product Details

- {{item.text}}

Quick Details

-

Max. Loading Capacity:

-

15000L

-

Weight (KG):

-

750 KG

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

JCT

-

Voltage:

-

220V/380V/440V

-

Dimension(L*W*H):

-

1200*500*1500-2500*800*2000

-

Power (kW):

-

55 kW

-

used in:

-

cosmetic, pesticides, dyes, building materials

-

motor:

-

explosion-proof

-

touch material:

-

SS304, 316

-

revolution:

-

2rpm

-

ratation:

-

63rpm

-

loading coefficient:

-

0.4-0.6

-

discharging mode:

-

dislocation bottom valve, butterfly bamper

-

other device:

-

outer jacket for heating and cooling, nebulizer

-

Power(W):

-

1.5KW~30KW

Quick Details

-

Barrel Volume (L):

-

15000

-

Max. Loading Volume (L):

-

15000 L

-

Range of Spindle Speed(r.p.m):

-

1 - 120

-

Max. Loading Capacity:

-

15000L

-

Weight (KG):

-

750 KG

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

JCT

-

Voltage:

-

220V/380V/440V

-

Dimension(L*W*H):

-

1200*500*1500-2500*800*2000

-

Power (kW):

-

55 kW

-

used in:

-

cosmetic, pesticides, dyes, building materials

-

motor:

-

explosion-proof

-

touch material:

-

SS304, 316

-

revolution:

-

2rpm

-

ratation:

-

63rpm

-

loading coefficient:

-

0.4-0.6

-

discharging mode:

-

dislocation bottom valve, butterfly bamper

-

other device:

-

outer jacket for heating and cooling, nebulizer

-

Power(W):

-

1.5KW~30KW

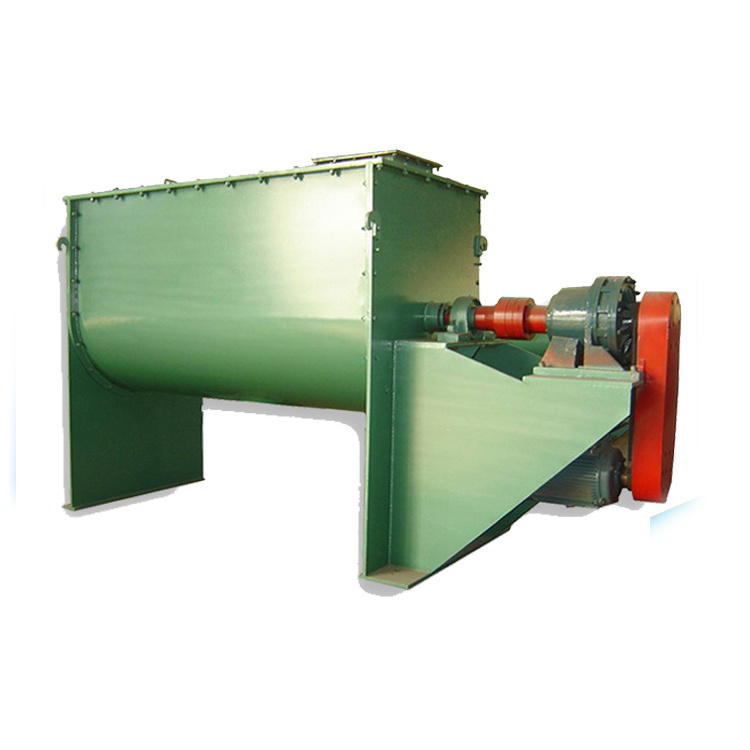

Cheap Granule Ribbon Mixer Of Compound Fertilizer Machinery

Ⅰ.

1. Description of horizontal ribbon mixer:

1) Horizontal ribbon mixer consists of U-shaped containers, ribbon mixing blade and transmission components.

2) The ribbon including continuous and disconnect.

3) The helical ribbon blade is made of a double or triple outer spiral the mateial from both sidesbrings together the central inner spiral the material transported from teh center to the sides to form a stream mixed.

2. Working performance:

1) Adding a liquid and pasty materials mixed in the ribbon mixer for viscous of cohesive ganule mixing and granule has a good effect, cylinder cover can be made of a wide-open door, so that the equipment for cleaning.

2) Can be added to the mixer barrel outer jacket, cooling or heating of the material is achieved by injecting the cooling medium to the jacket.

3) Discharge in the form of a phenomenon of material accumulation and mixing dead ends, reliable trim seal, frequent switching lakage.

We can design it as your requirement.

3. T echnical parameters of horizontal ribbon mixer:

| Model |

Volume (L) |

loading coefficient |

Motor power (KW) |

Speed (rpm) |

Remark |

| WLDH-0.5 | 500 | 0.4 ~ 0.6 | 4 ~ 7.5 | 42 |

Data in this table for reference, teh actual data according to specific proccess requirements, material viscosity, and other design.

|

| WLDH- 1 | 1000 | 0.4 ~ 0.6 | 5.5 ~ 11 | 42 | |

| WLDH- 2 | 2000 | 0.4 ~ 0.6 | 11 ~ 15 | 42 | |

| WLDH- 3 | 3000 | 0.4 ~ 0.6 | 15 ~ 18.5 | 42 | |

| WLDH- 4 | 4000 | 0.4 ~ 0.6 | 18 ~ 30 | 42 | |

| WLDH- 5 | 5000 | 0.4 ~ 0.6 | 22 ~ 37 | 42 | |

| WLDH- 6 | 6000 | 0.4 ~ 0.6 | 30 ~ 45 | 42 | |

| WLDH- 8 | 8000 | 0.4 ~ 0.6 | 37 ~ 55 | 42 | |

| WLDH- 10 | 10000 | 0.4 ~ 0.6 | 45 ~ 55 | 42 | |

| WLDH- 12 | 12000 | 0.4 ~ 0.6 | 45 ~ 75 | 42 | |

| WLDH- 15 | 15000 | 0.4 ~ 0.6 | 55 ~ 90 | 42 |

3. the picture of horizontal ribbon mixer :

Ⅱ.

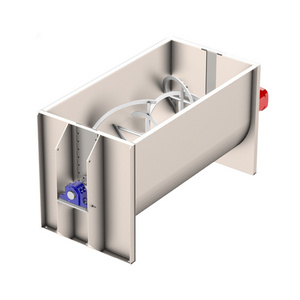

1. Discreption of conical twin screw mixer:

1) Conical twin screw with mixing machine mixing components for two asymmetrical cantilever screw, they around its axis of rotation (rotation) and at the same time, also around the conical container center shaft, with the help of a jib rotating in the cone surface of planetary motion (revolution).

2) The equipment through the revolution of the screw, rotation so materials again and again, to produce shear in the cone, convection, diffusion, etc compound movement, so as to achieve mixed purposes.

3) Products can be designed according to the outer jacket (heating, cooling), spray, etc.

4) Widely used in chemica, pesticide, pigment, building materials, such as powder mixed with powder.

5) DSH-0.1 mean 0.1m3 , 0.1m3 mean the volume 100L.

6) the mixing machine the touch material part make from stainless steel 304.

7) If you need more requirement , we can according to your require to design.

2. T echnical parameters

| type | design volume (L) | loading volume | motive power | discharge method | other require |

| DSH-0.1 | 100 | 60 | 1.1 | Displacement at the bottom of the valve or butterfly valve | Can design according to the jacket, the atomizer |

| DSH-0.3 | 300 | 180 | 1.5 | Displacement at the bottom of the valve or butterfly valve | Can design according to the jacket, the atomizer |

| DSH-05 | 500 | 300 | 2.2 | Displacement at the bottom of the valve or butterfly valve | Can design according to the jacket, the atomizer |

| DSH-1 | 1000 | 600 | 3-4 | Displacement at the bottom of the valve or butterfly valve | Can design according to the jacket, the atomizer |

| DSH-2 | 2000 | 1200 | 5.5-7.5 | Displacement at the bottom of the valve or butterfly valve | Can design according to the jacket, the atomizer |

| DSH-3 | 3000 | 1800 | 5.5-7.5 | Displacement at the bottom of the valve or butterfly valve | Can design according to the jacket, the atomizer |

| DSH-5 | 5000 | 3000 | 11-15 | Displacement at the bottom of the valve or butterfly valve | Can design according to the jacket, the atomizer |

| DSH-6 | 6000 | 3600 | 15-18.5 | Displacement at the bottom of the valve or butterfly valve | Can design according to the jacket, the atomizer |

| DSH-8 | 8000 | 4800 | 18.5-22 | Displacement at the bottom of the valve or butterfly valve | Can design according to the jacket, the atomizer |

| DSH-10 | 10000 | 6000 | 22-30 | Displacement at the bottom of the valve or butterfly valve | Can design according to the jacket, the atomizer |