- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

110V-415V

-

Power:

-

Accroding to model

-

Dimension(L*W*H):

-

Accroding to model

-

Weight (KG):

-

2000

-

Marketing Type:

-

Available

-

Evaporation Capacity(kg/h):

-

0.5KG-1000KG

-

norm:

-

3-1000

-

quantitative (science):

-

12-2500

-

treatment capacity:

-

1.5-1100

-

Fan power:

-

2.2KW-75KW

-

Steam consumption:

-

12kg-800kg

-

Compressed air consumption:

-

0.3-1.5

-

static (in a signal):

-

(Fan isolation installation)≤75

-

Overall dimensions:

-

Accroding to model

Quick Details

-

Type:

-

Fluid Bed Drying Equipment

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

longtai

-

Voltage:

-

110V-415V

-

Power:

-

Accroding to model

-

Dimension(L*W*H):

-

Accroding to model

-

Weight (KG):

-

2000

-

Marketing Type:

-

Available

-

Evaporation Capacity(kg/h):

-

0.5KG-1000KG

-

norm:

-

3-1000

-

quantitative (science):

-

12-2500

-

treatment capacity:

-

1.5-1100

-

Fan power:

-

2.2KW-75KW

-

Steam consumption:

-

12kg-800kg

-

Compressed air consumption:

-

0.3-1.5

-

static (in a signal):

-

(Fan isolation installation)≤75

-

Overall dimensions:

-

Accroding to model

Product descriptions from the supplier

Working Principle:

- Material powder or particles, in the raw material container (fluidized bed) in the boiling fluidization state, by the purification of the heated air preheating and stirring, due to the continuous drying effect of the hot air on the material, so that the moisture in the agglomerate evaporates, the process is repeated, the formation of ideal, uniform, porous spherical particles.

Fields of application:

- Pharmaceutical granulation and coating

Granulation: granules for tablets, granules for punch, granules for capsules.

Coating: granule, pill protective layer, color preparation, slow release, film, enteric coating.

- Food granulation and coating

Sugar, coffee, cocoa powder, cream, powdered juice, amino acid, seasoning, puffed food.

- Pesticides, pigment coloring, dyes granulation

- Powder, granule, lump material drying

Performance Characteristics:

- Improve its flowability through powder granulation and reduce dust flying;

- Improve its dissolving property through powder granulation;

- Mixing-granulating-drying-completed in one machine (one-step granulation);

- Adopting anti-static filter material, the equipment is safe to operate;

- The binder atomizer adopts multi-fluid spray gun, the fog particles are uniform, and the qualified rate of finished products is greatly improved;

- No dead angle of the equipment, easy and fast loading and unloading, clean rinsing.

Process Demonstration:

Process Demonstration Diagram 1

Process Demonstration Diagram 2

Process Demonstration Diagram 3

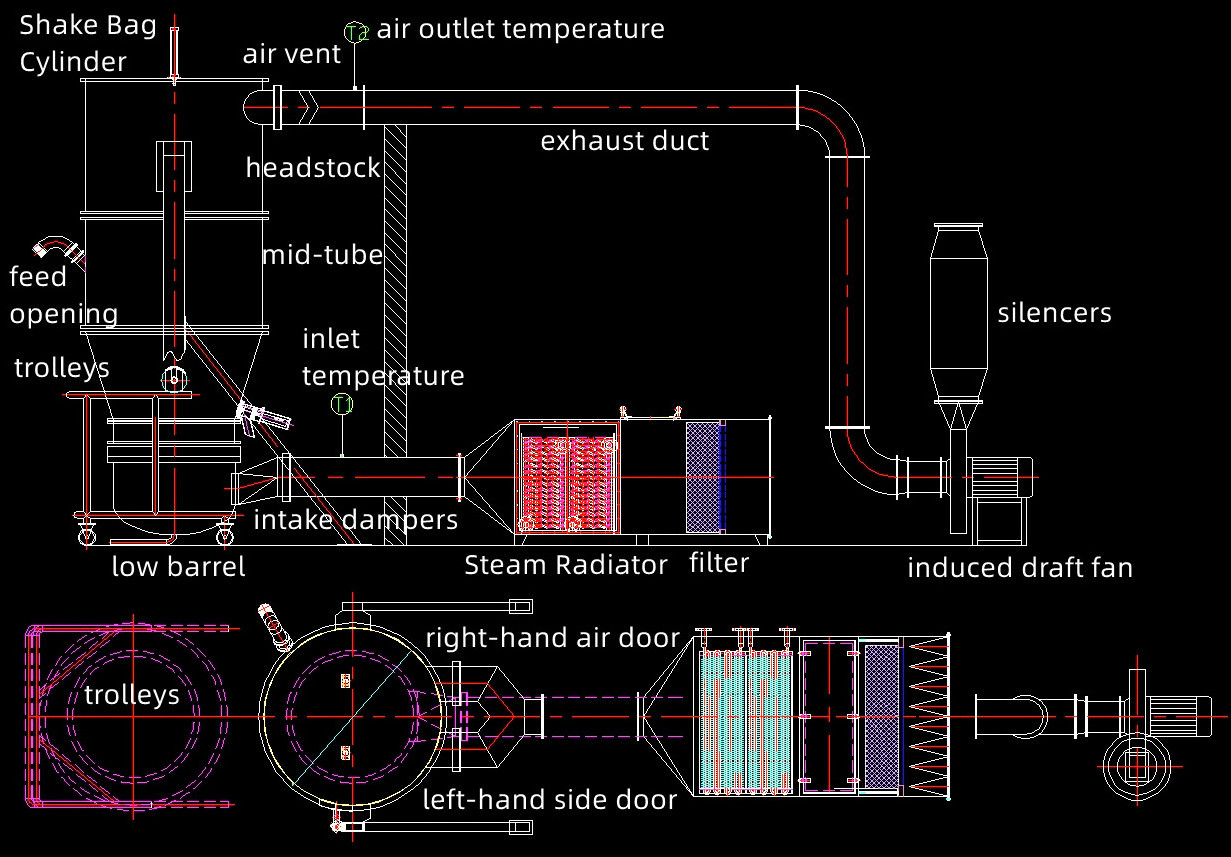

Structure:

This machine is composed of air filtering device, air heating, drying bed, diffusion room, filtering room, exhaust duct, induced draft fan, silencer, control cabinet and so on.

1 , Main machine The main machine consists of bottom section air inlet room, drying bed, diffusion room (including vacuum inlet), and filtration room.

2 , Air filtration device The air filter is divided into primary and secondary pre-filter, and high efficiency filter to ensure that the incoming air reaches 100,000 purification level to meet the GMP requirements, and the medium and high efficiency filters are equipped with differential pressure display before and after the filter.

3 , Air heater The air heater is a steam heater, made of all stainless steel, and the temperature fluctuation range of the inlet air is ± 2℃.

4, the exhaust system consists of exhaust pipe, induced draft fan, silencer, induced draft fan and the host isolated installation, the noise ≤ 75 dB, the air volume is frequency conversion speed control, can be continuously adjusted

state of fluidization, so the machine is suitable for feeding a wide range of materials, but also well adapted to the requirements of the air volume of the different materials granulation.

5 , Control system It is composed of touch screen, PLC programmer frequency converter and temperature controller, etc. It adopts PID technology to precisely control the temperature of inlet air and real-time detection and display of the temperature of exhaust air, so as to effectively control the drying process.

technical specification:

|

norm |

3 |

5 |

15 |

30 |

45 |

60 |

90 |

120 |

150 |

200 |

300 |

500 |

1000 |

|

quantitative (science) |

12 |

22 |

45 |

100 |

155 |

220 |

300 |

420 |

530 |

660 |

1000 |

1500 |

2500 |

|

treatment capacity |

1.5/4.5 |

4/6 |

10/20 |

15/45 |

25/65 |

40/80 |

60/120 |

80/160 |

90/200 |

100/300 |

150/450 |

300/550 |

500/1100 |

|

Fan power |

2.2 |

3 |

4 |

5.5 |

7.5 |

11 |

15 |

18.5 |

18.5 |

22 |

30 |

37 |

75 |

|

Steam consumption |

12 |

23 |

42 |

70 |

99 |

141 |

169 |

211 |

251 |

282 |

366 |

451 |

800 |

|

Compressed air consumption |

0.3 |

1.3 |

0.3 |

0.4 |

0.4 |

0.6 |

0.6 |

0.9 |

0.9 |

0.9 |

1.3 |

1.5 |

1.5 |

|

static (in a signal) |

(Fan isolation installation) ≤75 |

||||||||||||

|

Overall dimensions |

1.0

|

1.2

|

1.25

|

1.6

|

1.65

|

1.85

|

1.85

|

2.2

|

2.27

|

2.34

|

2.8

|

3

|

4.5

|

Equipment Picture:

WHY CHOOSE US:

Packaging & Shipping :