- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

PFA-G-002

-

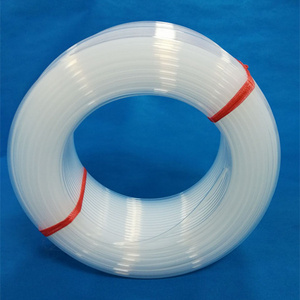

Specification:

-

2-160mm;customized

-

Length:

-

100m;customized

-

Thickness:

-

0.1-2mm;customized, 0.1-2MM

-

Standard:

-

ROHS;ISO9001

-

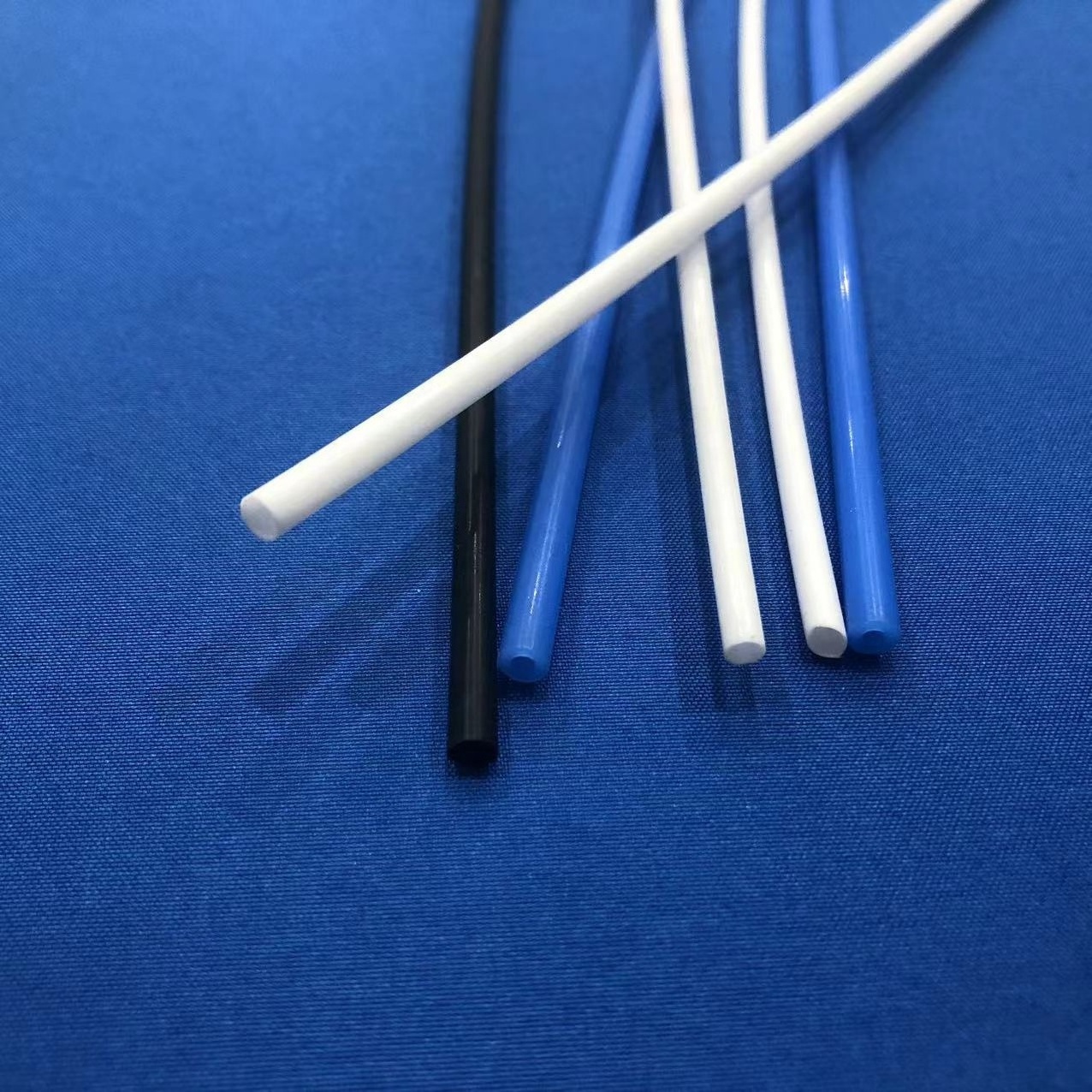

Color:

-

customized

-

Application:

-

High Temperature; conveying liquids and gasoline

-

Tensile Strength:

-

>=14MPa

-

Working Temperature:

-

-85°C~260℃

-

Resistance:

-

wear resistance, anti-acid and anti-virus,solvent resistance,etc

-

Product name:

-

Xinfu

-

Size:

-

2-160MM

-

Sample:

-

Provide Samples

Quick Details

-

Processing Service:

-

Moulding, Cutting

-

Place of Origin:

-

Anhui, China

-

Brand Name:

-

XinFu

-

Model Number:

-

PFA-G-002

-

Specification:

-

2-160mm;customized

-

Length:

-

100m;customized

-

Thickness:

-

0.1-2mm;customized, 0.1-2MM

-

Standard:

-

ROHS;ISO9001

-

Color:

-

customized

-

Application:

-

High Temperature; conveying liquids and gasoline

-

Tensile Strength:

-

>=14MPa

-

Working Temperature:

-

-85°C~260℃

-

Resistance:

-

wear resistance, anti-acid and anti-virus,solvent resistance,etc

-

Product name:

-

Xinfu

-

Size:

-

2-160MM

-

Sample:

-

Provide Samples

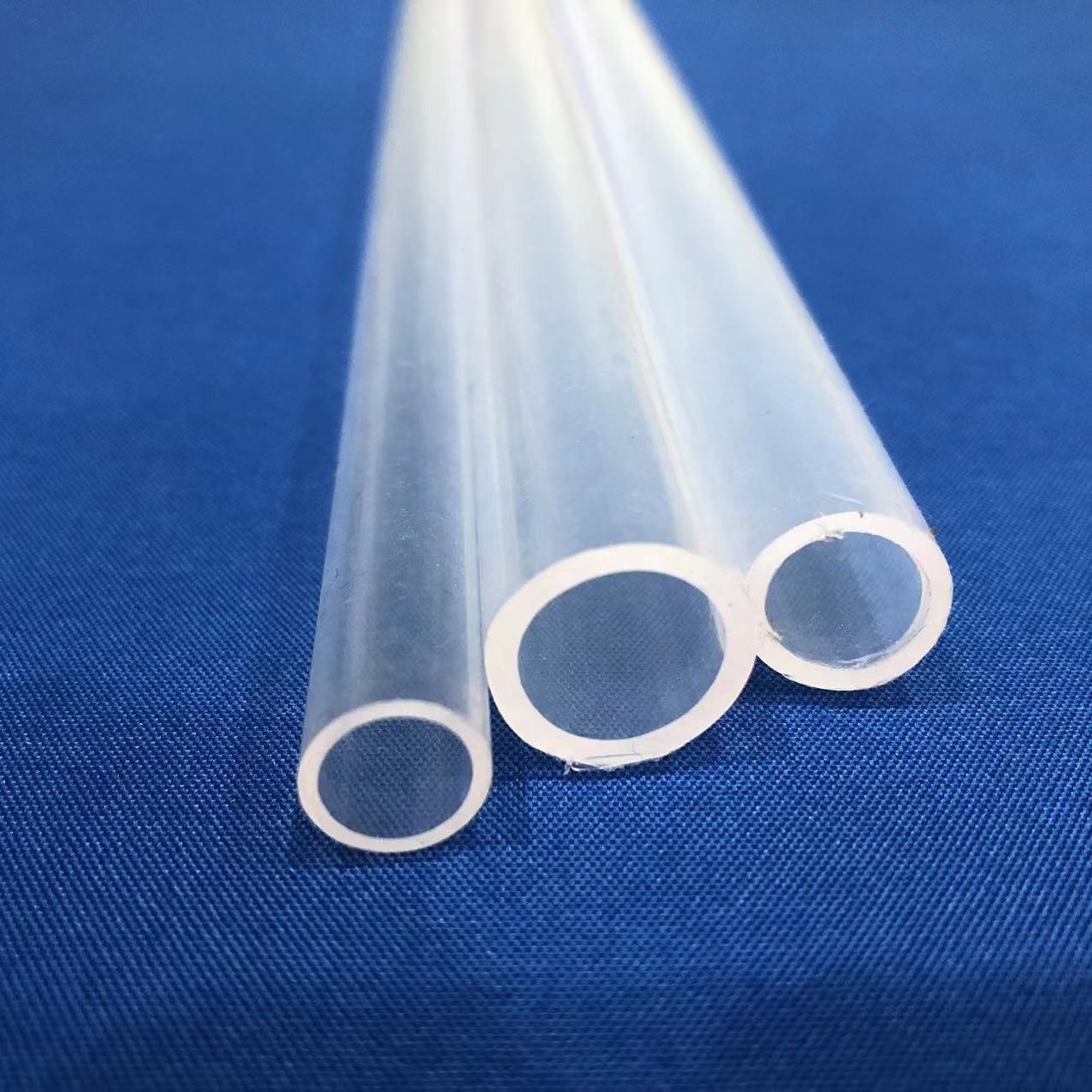

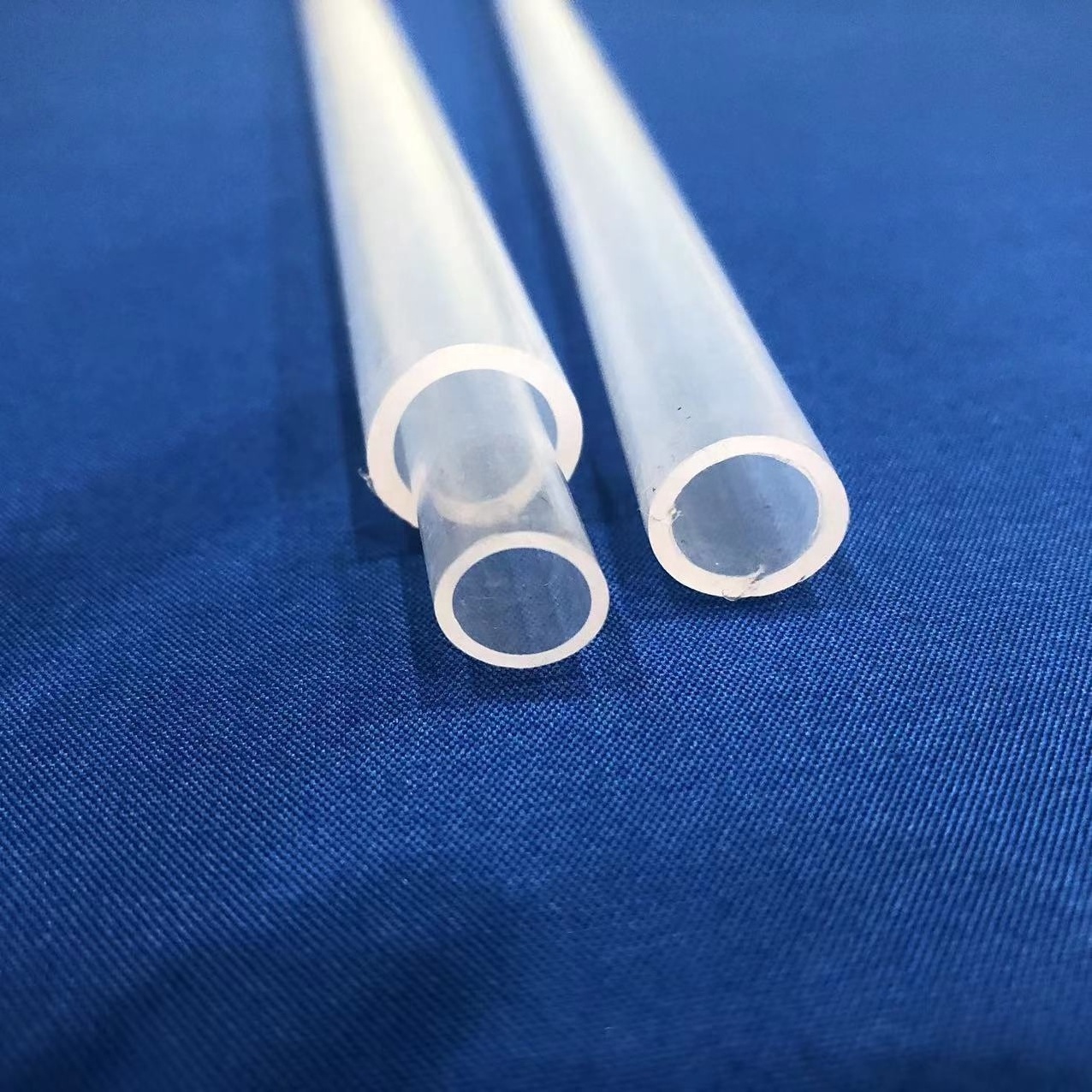

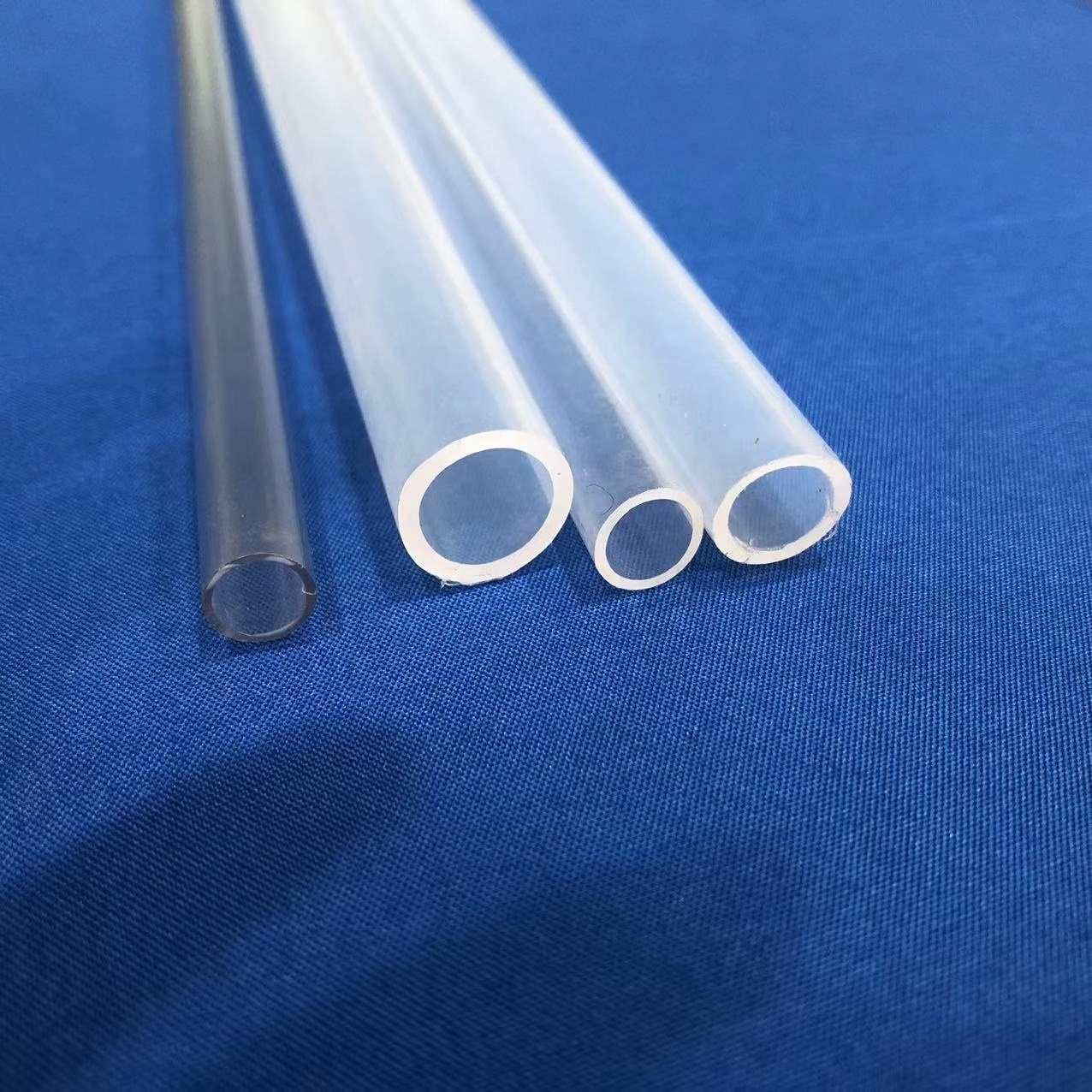

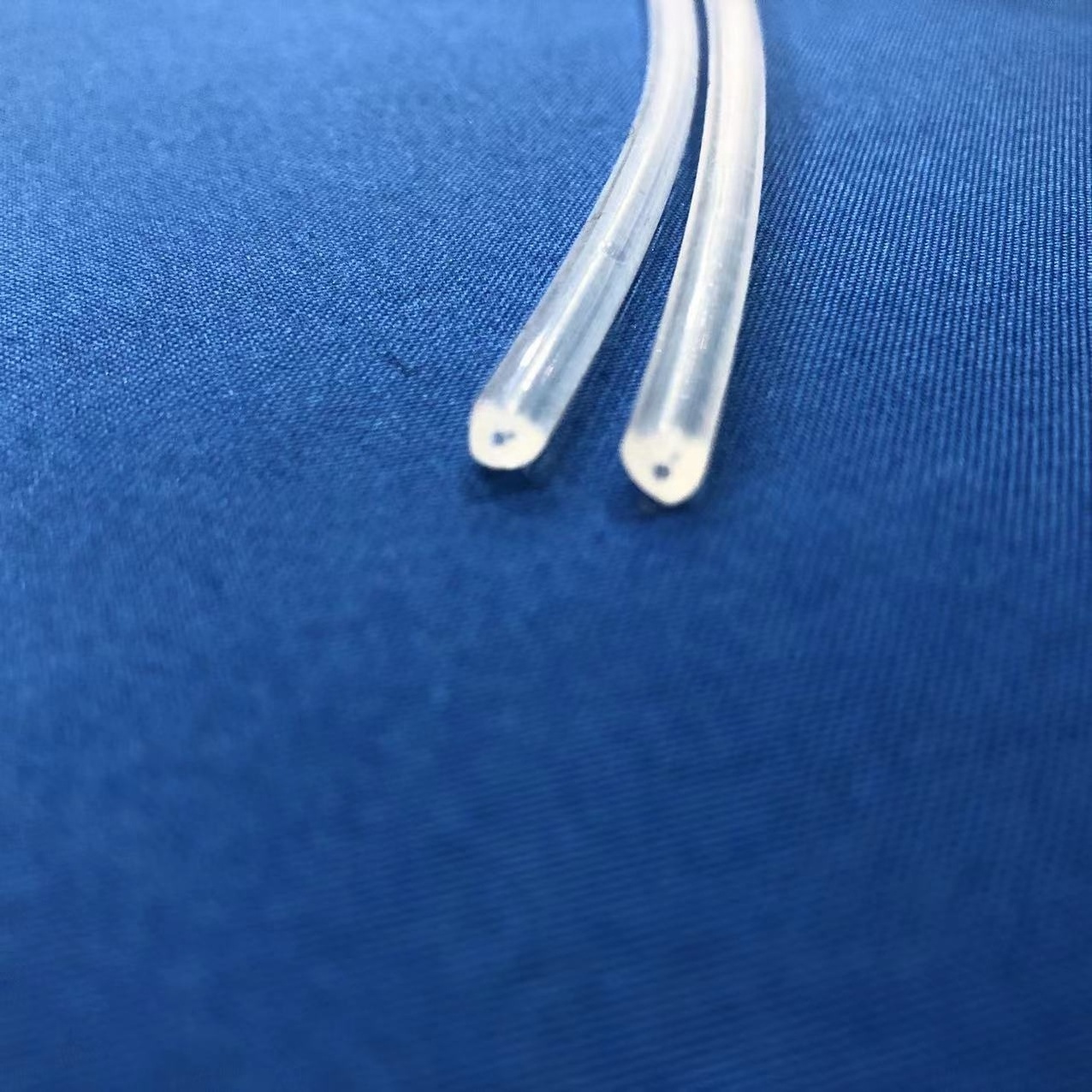

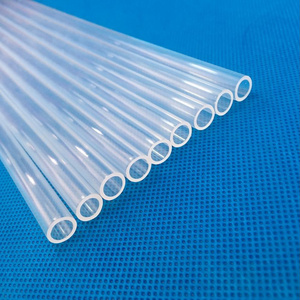

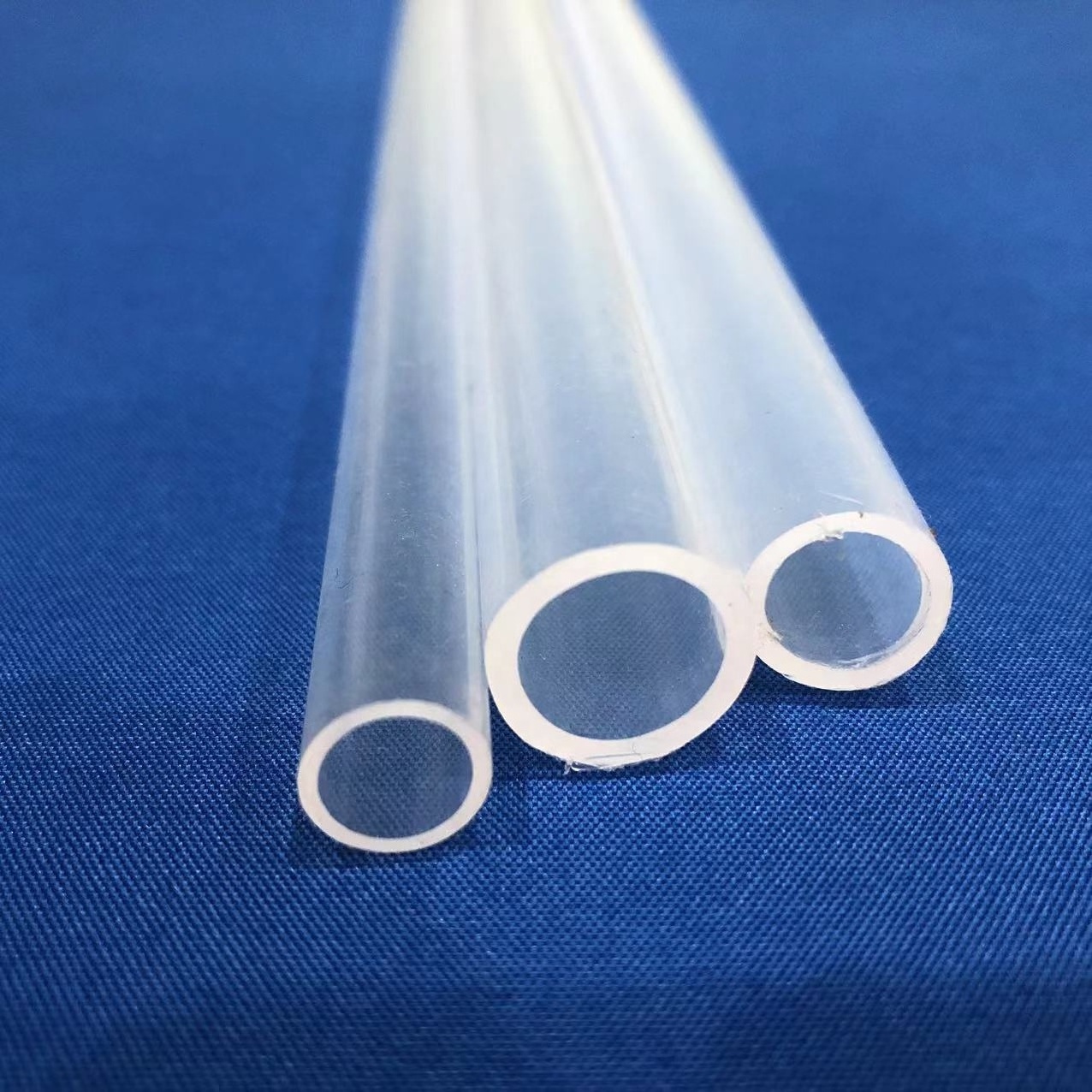

Product Description

|

Material

|

PFA

|

|

Color

|

customized

|

|

Thickness

|

0.1-2MM

|

|

Size

|

2-160MM

|

|

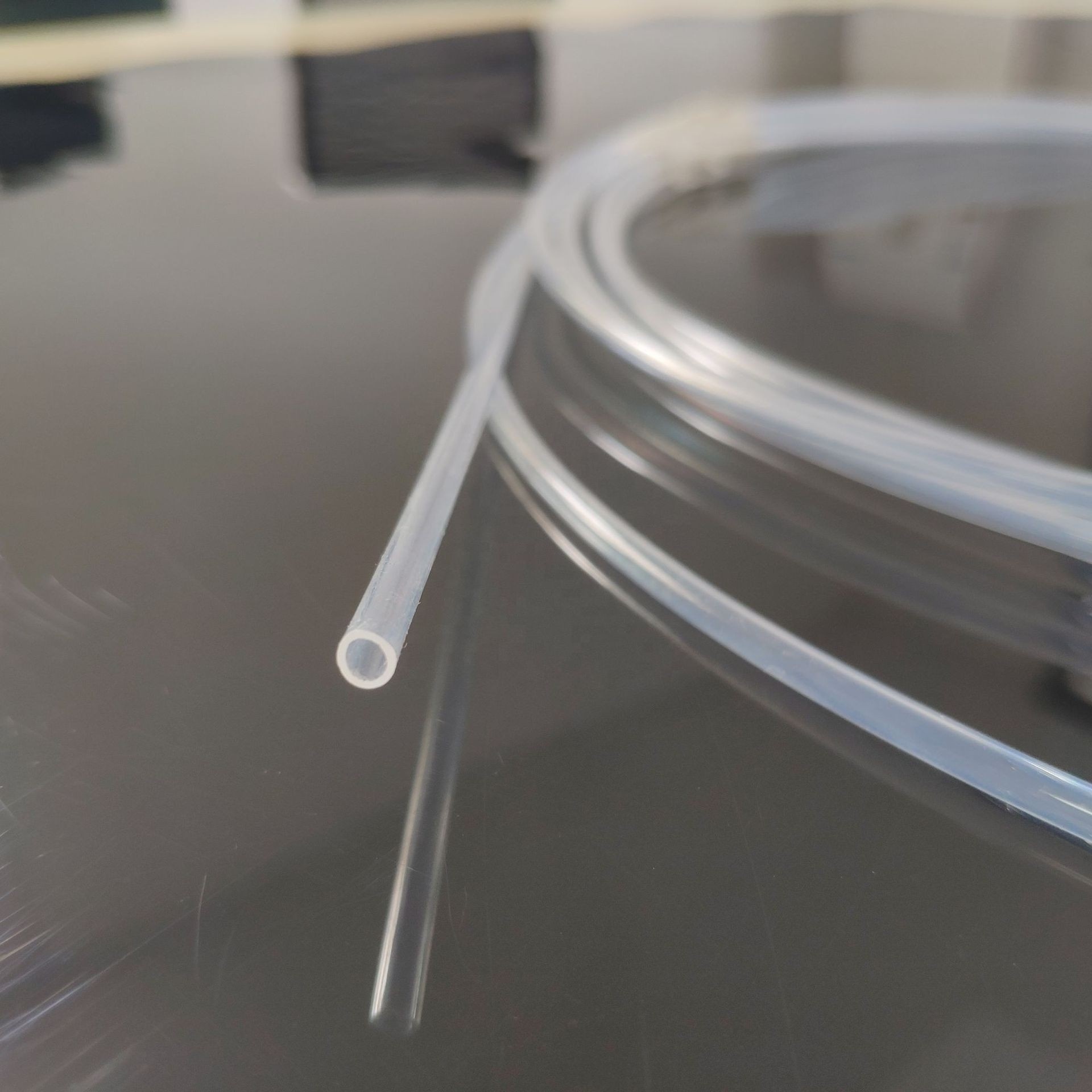

Working temperature

|

-85°C~260℃

|

|

Usage

|

widely used in pesticides, sulfuric acid filling machine, food fillers, oils filling machine, medical equipment, all kinds

instrumentation, automotive oil tube , mechanical,electrical appliances, automotive,aerospace,chemical,pharmaceutical,communications and other fields.such as food processing,high temperature fluid,chemicals and compressed gas. * Cooling solution for the pharmaceutical industry, is highly corrosive liquid cooling conveyor * Wire corrosion protection tube and transfer the liquid medium, ultra-pure water pipe and other equipmen |

|

Introduction

|

In recent years, plastic has emerged as a reliable and cost-effective alternative material for manufacturing pipes, even though it

was not originally considered suitable for piping process environments. There is now a broad range of plastic compounds being developed, making it a viable option for many industries. The two most effective categories of plastic for piping systems are fluoroplastics and thermoplastics. Fluoroplastics, such as PTFE, PVDF, ECTFE, CTFE, PFA, and FEP, are particularly well-suited for use in aggressive chemical services at extreme temperatures, ranging from -328°F to +500°F. Thermoplastics, on the other hand, require melting during the manufacturing process and can be welded or injection-molded into shapes for machining into piping system components. The use of plastics in piping systems has become essential in some cases, as pipes made from plastic have proven to be more cost-effective and reliable than traditional materials like glass or ceramic-lined pipes. Plastics such as UHMW PE, PVDF, CTFE, and nylon have been shown to offer excellent wear resistance and can perform up to five to ten times better than 304 Stainless Steel in Taber Abrasion Tests. These tests measure the amount of weight loss after 1,000 cycles of an abrasive wheel over a plate made of the tested material. In conclusion, plastic has become a popular choice for manufacturing pipes due to its cost-effectiveness, reliability, and wide range of plastic compounds available. With fluoroplastics and thermoplastics being the most effective categories for piping systems, plastics have proved to be a suitable alternative for many industries |

Application

widely used in pesticides, sulfuric acid filling machine, food fillers, oils filling machine, medical equipment, all kinds

instrumentation, automotive oil tube ,

mechanical,electrical appliances,

automotive,aerospace,chemical,pharmaceutical,communications and other fields.such as food processing,high temperature

fluid,chemicals and compressed gas.

* Cooling solution for the pharmaceutical industry, is highly corrosive liquid cooling conveyor

* Wire corrosion protection tube and transfer the liquid medium, ultra-pure water pipe and other equipmen

Hot Searches