- Product Details

- {{item.text}}

Quick Details

-

Brick size:

-

400*100*200 mm, 400*120*200 mm, 200*100*60 mm, 300*150*100 mm, 400*150*200 mm, 240*115*90 mm, 200*200*60 mm, 150*150*100 mm, 400*200*200 mm, 230*220*115 mm

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Yuanhang

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

5.9*2.5*2.5m

-

Weight (KG):

-

20000 kg

-

Product Type:

-

Fired Clay Brick Production Line

-

After-sales Service Provided:

-

Brick Machine

-

Feature:

-

Automatic Brick Machine

-

Strength:

-

Easy Operate De-airing Brick Machine

-

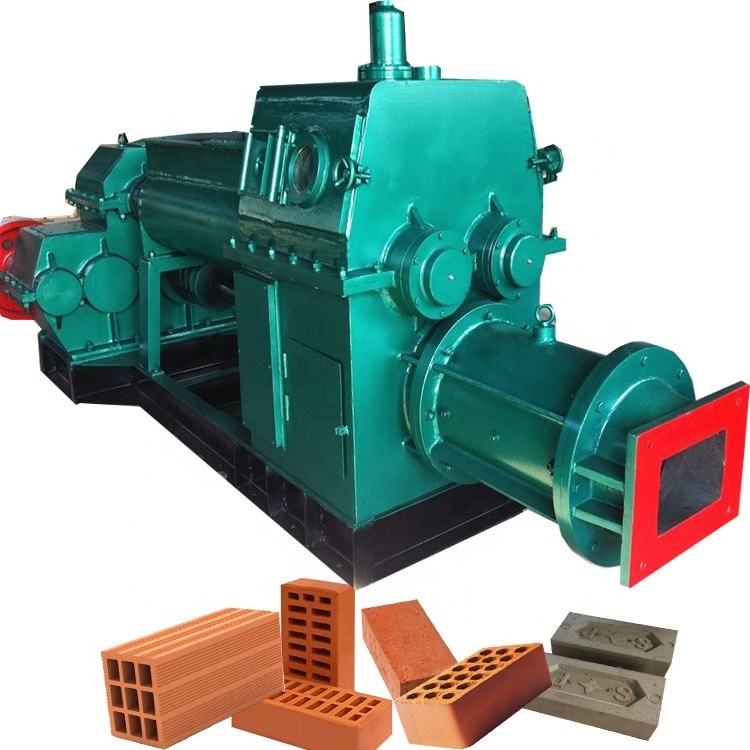

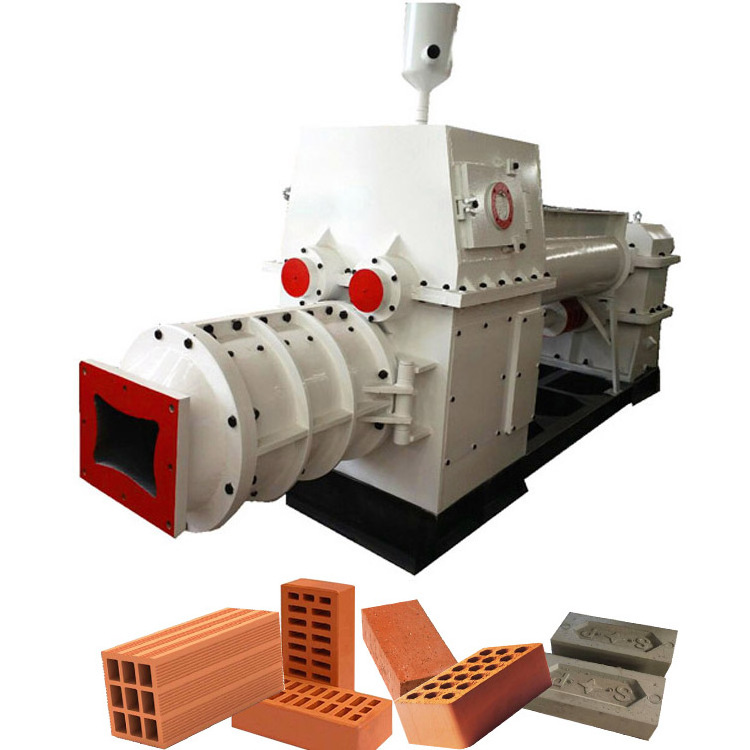

Color:

-

White ,Green, designated color is available

-

Vacuum Degree:

-

≤-0.092mpa

-

Raw material:

-

Clay,Coal gangue,Shale,Fly Ash ,others

-

Product Name:

-

Brick Making Machine

-

Name:

-

Clay Brick Making Machine

-

Keywords:

-

Clay Logo Brick Making Machine

Quick Details

-

Type:

-

Hollow Block Making Machine, Paving Block Making Machine, Interlock Block Making Machine, Curbstone Block Machine, Other, solid or Hollow Brick Making Machine Solid Brick Making Machine

-

Brick Raw Material:

-

Clay,Coal gangue,Shale,Fly Ash ,others

-

Production Capacity (Pieces/8 hours):

-

10000-15000bricks/hr

-

Brick size:

-

400*100*200 mm, 400*120*200 mm, 200*100*60 mm, 300*150*100 mm, 400*150*200 mm, 240*115*90 mm, 200*200*60 mm, 150*150*100 mm, 400*200*200 mm, 230*220*115 mm

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Yuanhang

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

5.9*2.5*2.5m

-

Weight (KG):

-

20000 kg

-

Product Type:

-

Fired Clay Brick Production Line

-

After-sales Service Provided:

-

Brick Machine

-

Feature:

-

Automatic Brick Machine

-

Strength:

-

Easy Operate De-airing Brick Machine

-

Color:

-

White ,Green, designated color is available

-

Vacuum Degree:

-

≤-0.092mpa

-

Raw material:

-

Clay,Coal gangue,Shale,Fly Ash ,others

-

Product Name:

-

Brick Making Machine

-

Name:

-

Clay Brick Making Machine

-

Keywords:

-

Clay Logo Brick Making Machine

Automatic clay auto JKR30 brick making machine manual

Brick Making Equipment

The vacuum extruder adopts all-steel design, and the reamer is designed according to the nature of the raw material. The machine is a split type upper and lower level all-steel structure, driven by two motors separately, with advanced technology, high extrusion pressure, high output, high vacuum, sturdiness and durability, etc., especially suitable for the production of solid bricks and high porosity Brick can be applied to a variety of raw materials, such as coal gangue, shale, clay, fly ash, etc., and is the most popular brick machine equipment at the moment.

The vacuum extruder adopts all-steel design, and the reamer is designed according to the nature of the raw material. The machine is a split type upper and lower level all-steel structure, driven by two motors separately, with advanced technology, high extrusion pressure, high output, high vacuum, sturdiness and durability, etc., especially suitable for the production of solid bricks and high porosity Brick can be applied to a variety of raw materials, such as coal gangue, shale, clay, fly ash, etc., and is the most popular brick machine equipment at the moment.

Lower Price vacuum extruder clay automatic brick making machine

Product Paramenters

|

Type

|

Capacity(pcs/hr)

|

Forming moisture

|

Vacuum Degree(Mpa)

|

Power(kw)

|

|

JKR/JZKE50-3.0

|

12000-16000

|

17%-19%

|

≤-0.092

|

160+7.5

|

|

JKR/JZKE45-3.0

|

10000-15000

|

17%-19%

|

≤-0.092

|

132+5.5

|

|

JKR/JZKE40-3.0

|

8000-12000

|

17%-19%

|

≤-0.092

|

110+5.5

|

|

JZKD40-3.0

|

10000-12000

|

17%-19%

|

≤-0.092

|

110+5.5

|

|

JZKD35-3.0

|

8000-10000

|

17%-19%

|

≤-0.092

|

90+5.5

|

Application field

Various raw materials applicable: Clay, Coal Gangue, Shale, Fly ash , slag etc.

Pls kindly note the output is based on Chinese standard brick (240*115*53 mm), you can give us your brick size and we

areresponsible to recommend the brick machine you need.

areresponsible to recommend the brick machine you need.

Specifications of Brick Making Equipment

1. high quality carbon and alloy steel weld , remove welded stress by quench’s heat handling

2. use floating trowel with wearresistant metallization technology ,

3. reasonable structure , optional installation , high pressure extrude

4. low energy consumption , high capacity , easy operation and maintenance

5. ISO 9001 ; 2008

6. suitable for various of multi-hole , solid and hollow bricks with shale , coal gangue , coal ash , clay , industrial tailings and other raw material Clay

Brick Making

machinery

7. different soil quality and material adjust technical parameter

Products Description

The power consumption of vacuum clay brick making machine is low, and the saving rate is up to 40 percent.

The vacuum brick making machine

low price

has a higher degree of automation and higher output.

The clay brick machine produced by our factory is widely used to produce various specifications of hollow bricks from shale, fly ash, coal gangue, clay and other raw materials. The machine has strong practicability, small investment and quick results. It is an ideal equipment for small and medium-sized brick factories. Auxiliary equipment for clay brick making machine: automatic strip cutting system, box feeder, SJ series double-shaft mixer, roller mill, vertical strip cutting machine, falling plate machine, etc.

vacuum extruder

Customer case

We select the most suitable product model for you according to customer requirements, provide delivery pictures and videos, and provide customers with installation, commissioning and technical training services. Let customers rest assured to use.

FAQ

Q1: What is the warranty for this machine?

A1: 3 years excluding the easy wear parts.Spare parts is recommended to keep at least one year in case of emergency

Q2: What kind of material is this machine made of ?

A2: Stainless steel and carbon steel.

Q3: When can I get the price?

A3: Within 24 hours. If urgent, please directly call us.

Q4: Can the price be much lower?

A4: Our MOQ is the very reasonable price for 1 set, but with big order, we can apply to our Manager to provide a proper discount.

Q5: Do you offer oversea installation?

A5: We'll send professional installation engineer to help you install the equipment, as well as train your workers freely.

Hot Searches