- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

5620*2260*1900mm

-

Power (kW):

-

200 kW

-

Weight (KG):

-

25000 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

colour:

-

blue or as customers'demand

-

output:

-

20,30,40,60,80mesh rubber powder

-

type of raw material:

-

truck tire,radial tire,nylon tire

-

design:

-

design and install by professional engineer

-

category:

-

Rubber Raw Material Machinery

-

process range:

-

750-1200mm tire

-

consuming power:

-

50-125kw

-

machine type:

-

semi-automatically and fully automatically

-

advantage:

-

High Producing Efficiency

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

xinyutian

-

Voltage:

-

Customer Request

-

Dimension(L*W*H):

-

5620*2260*1900mm

-

Power (kW):

-

200 kW

-

Weight (KG):

-

25000 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

colour:

-

blue or as customers'demand

-

output:

-

20,30,40,60,80mesh rubber powder

-

type of raw material:

-

truck tire,radial tire,nylon tire

-

design:

-

design and install by professional engineer

-

category:

-

Rubber Raw Material Machinery

-

process range:

-

750-1200mm tire

-

consuming power:

-

50-125kw

-

machine type:

-

semi-automatically and fully automatically

-

advantage:

-

High Producing Efficiency

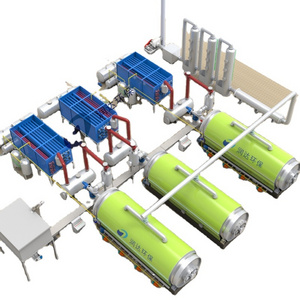

---Brief introduction

it is to recycle different types tire(radial tire,nylon tire) into rubber powder(30-100mesh)free of steel and fiber which includes machines listed below,

*cutter

*shredders

*specially designed powder crusher capable of wires and fiber separation

*vibratory screens and demagnetizers

*complete turkey plants with produiction capacities from 1ton per hour to 10;whatever capacities

you require.

First step: 1.cut both sidewalls from whole tires(10seconds)

2.remove bead wires from tire sidewalls(capacity is 1minites per tires )

Second step:shredder tire sidewalls and treads into 6-8cm.

Third step:recycle 6-8cm tire shredded into 1-5mm/30mesh crumb rubber and rubber powder

automatically.

---Output

---Advantages

*our rubber powder making machine is extremely cost-effective and designed for your company's growth.

*all plants are easily upgradable on a modular system.

*the machinery is ergoomically friendly and designed to meet european safety and electrical standards

*if time,effeciency and quality end product is something you seek,we have the answers.

*apart from the building and wiring of the building 's electric system,we providethe lot including installation,

training of staff and ongoing consulation.equipment is ont simple delivered,set up and then left to your own devices,we are there to guide through.

Pre sales

1.customizes to suit customers’exact needs

2.recommend suitable machines configuration accordance to actual situation from customers.

After deal

1.provide details building factory plan

2.provide technical service like foundation making drawing,layout drawing(CAD drawing)

After sale

1.warranty for one year

2. provide technical tracking and service

3.come up with best solution within 24hours whenever customers have any questions.(specifi video,photos will be provided for explain )