- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Seanoel

-

Power:

-

100000 W

-

Dimension(L*W*H):

-

15*10*3M

-

Weight:

-

12000 KG

-

Production Capacity:

-

100-400KG/H

-

Name:

-

Polyester Wadding Machine

-

Wadding Type:

-

Thermal Bonding

-

Heating Type:

-

Electric Oven or Gas Oven

-

Bonding Type:

-

Low Melting Fiber Without Glue

-

Finish Product Width:

-

2000-4000MM

-

Finish Product Weight:

-

40-800GSM

-

Capacity:

-

100-400KG/H

-

Raw material:

-

Polyester Stable Fiber

-

Finished Product:

-

Wadding Roll & Wadding Sheet

-

Company Type:

-

Manufacturer Since 2003

Quick Details

-

Voltage:

-

380V 50HZ

-

Marketing Type:

-

New Product 2022

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Seanoel

-

Power:

-

100000 W

-

Dimension(L*W*H):

-

15*10*3M

-

Weight:

-

12000 KG

-

Production Capacity:

-

100-400KG/H

-

Name:

-

Polyester Wadding Machine

-

Wadding Type:

-

Thermal Bonding

-

Heating Type:

-

Electric Oven or Gas Oven

-

Bonding Type:

-

Low Melting Fiber Without Glue

-

Finish Product Width:

-

2000-4000MM

-

Finish Product Weight:

-

40-800GSM

-

Capacity:

-

100-400KG/H

-

Raw material:

-

Polyester Stable Fiber

-

Finished Product:

-

Wadding Roll & Wadding Sheet

-

Company Type:

-

Manufacturer Since 2003

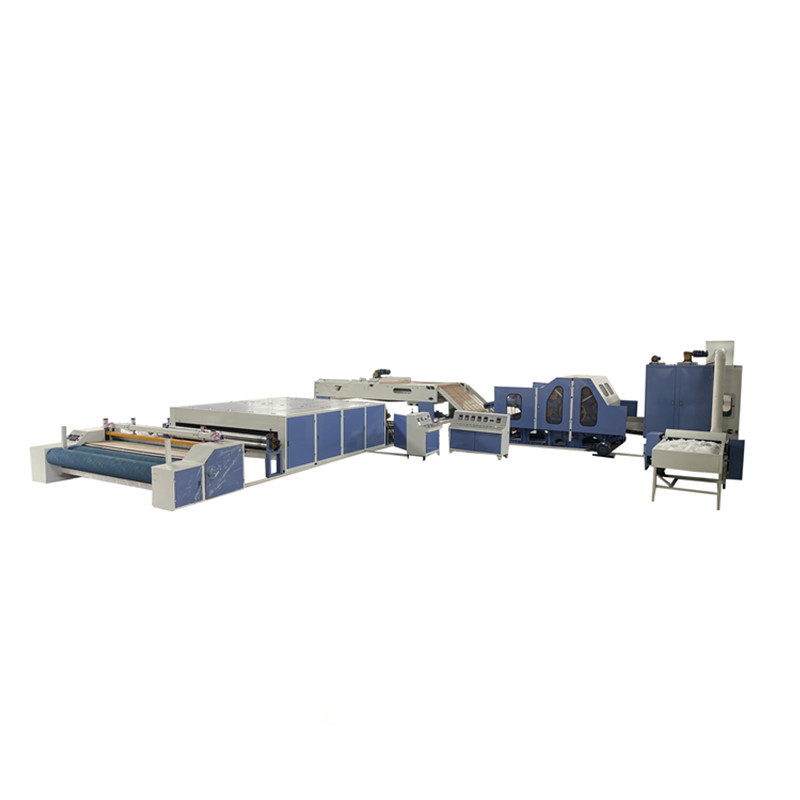

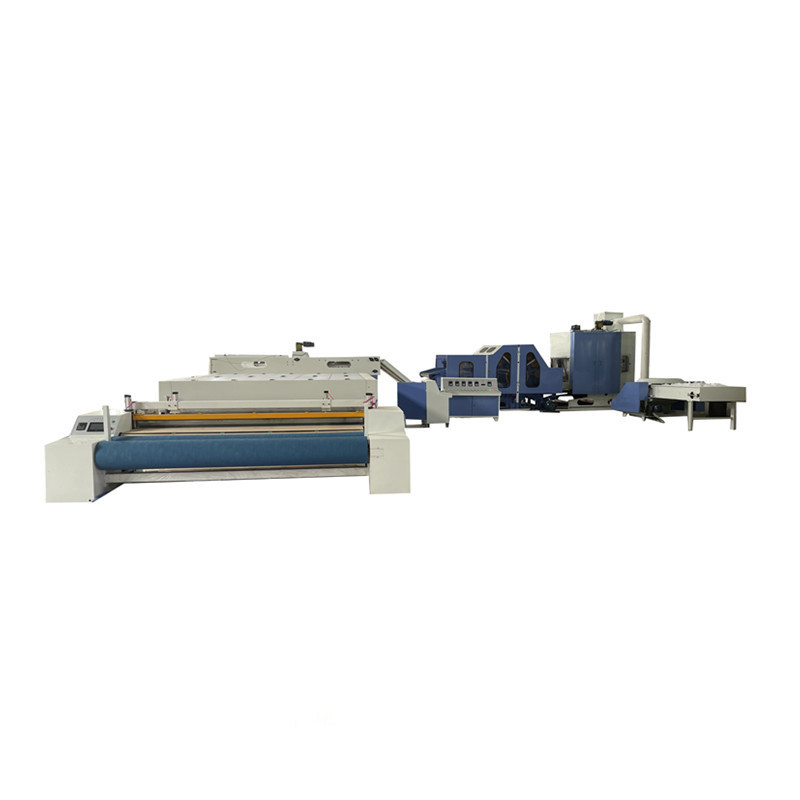

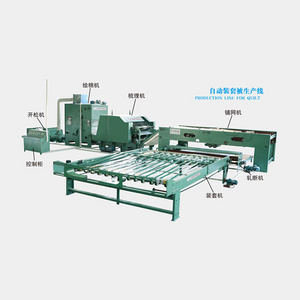

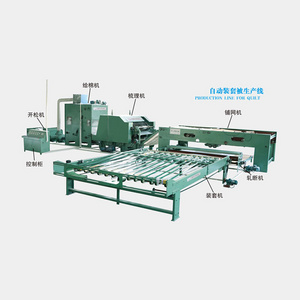

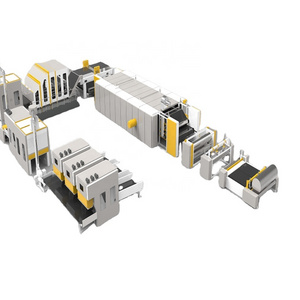

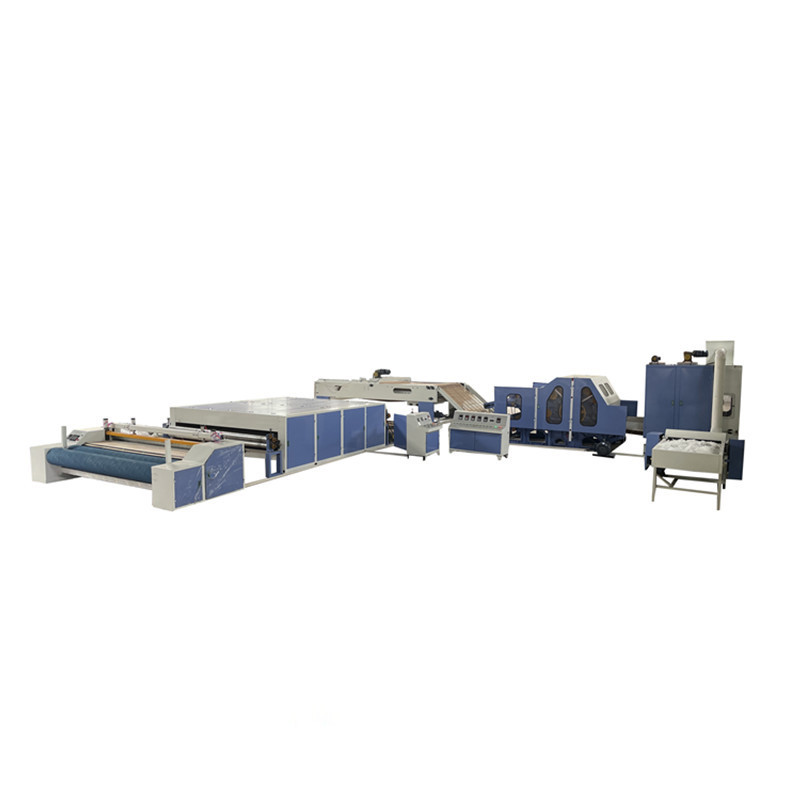

Non-Glue Polyester Wadding Roll Production Machine

operation,

According to customer demands,adopt different configurations,finished products can be used for quilt,

mattress,cloth,sofa,cushion,car seat and etc.

2.Weighing different specifications fiber one by one and mixing them evenly ,feeding to opening machine ,real machine is blue and

white color

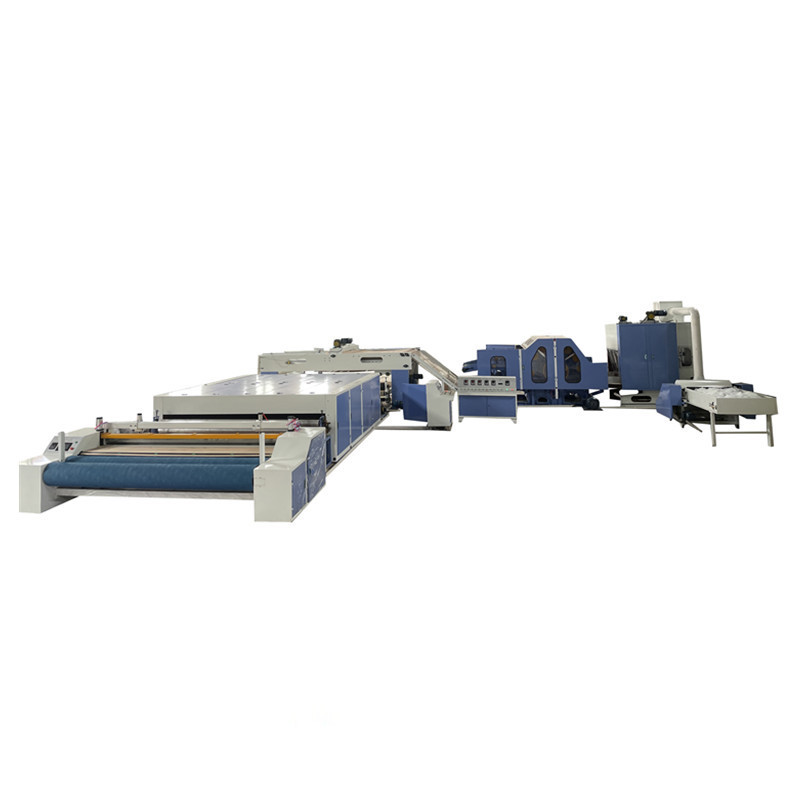

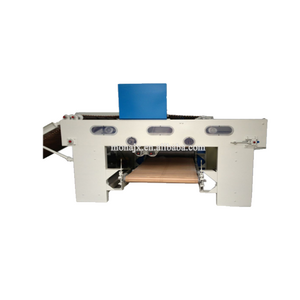

3.Open the compressed fiber raw materials into fluffy fibers and transport them to feeding box

4.To collect the fluffy fibers which delivered by the opening machine and evenly transport those fibers to carding machine

5.Opening and combing fiber into fibrous layer , after being combed by freedom rollers,the fiber in fibrous layer will be

intertwined more closely.

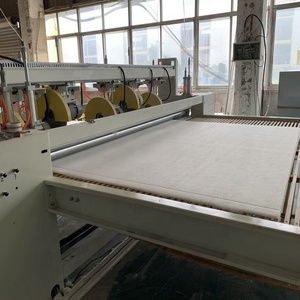

6.By folding the fiber layer back and forth, continuous formation of a fiber layer with a certain width and thickness

7.When fiber layer passes through oven, the high temperature causes the low-melting chemical fiber melting in the entire fiber

layer. After cooling, it binds all the fibers together like glue, but more environmentally friendly

8.Trimming layer edges by press knife,Coiling the layer in to roll by the cloth roller,Set required roll length on PLC. When the

length reaches the set value, the cross-cutting knife will work automatically to cut the fiber layer transversely

|

Model

|

SN-WDL850

|

SN-WDL1230

|

SN-WDL1850

|

SN-WDL2000

|

|||

|

Floor Size

|

15*10*2.5M

|

15*10*2.5M

|

16*10*2.5M

|

16*10*2.5M

|

|||

|

Max Product Width

|

2800-3000-3200-3600-4000MM-6000MM OPTIONAL

|

1700KG

|

3KW

|

-

|

|||

|

Wadding Density

|

60-800GSM

|

6600KG

|

18KW

|

Working Width 1550,1850,2300

|

|||

|

Output

|

80-150KG/H

|

150-200KG/H

|

200-300KG/H

|

300-400KG/H

|

|||

|

Power(Gas/Electric)

|

42/97KW

|

46/100KW

|

54/130KW

|

56/135KW

|

|||

|

Finished Product

|

Polyester Wadding Roll & Non-glue Cotton Sheet

|

1600KG

|

3KW

|

-

|

|||

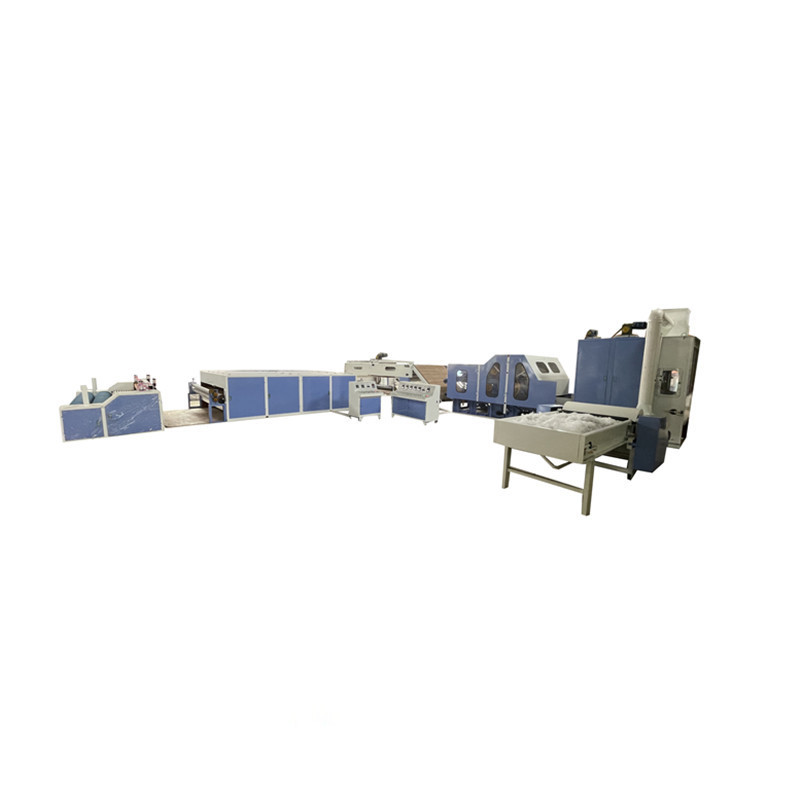

Opening Machine

Feeding Box

Carding Machine

Cross Lapper

Electric Oven

Cutting & Rolling Machine

Electric Weighing Bale Opener

Electric Ironing Machine

Wadding Roll Package Machine

Production Details

Hot Searches