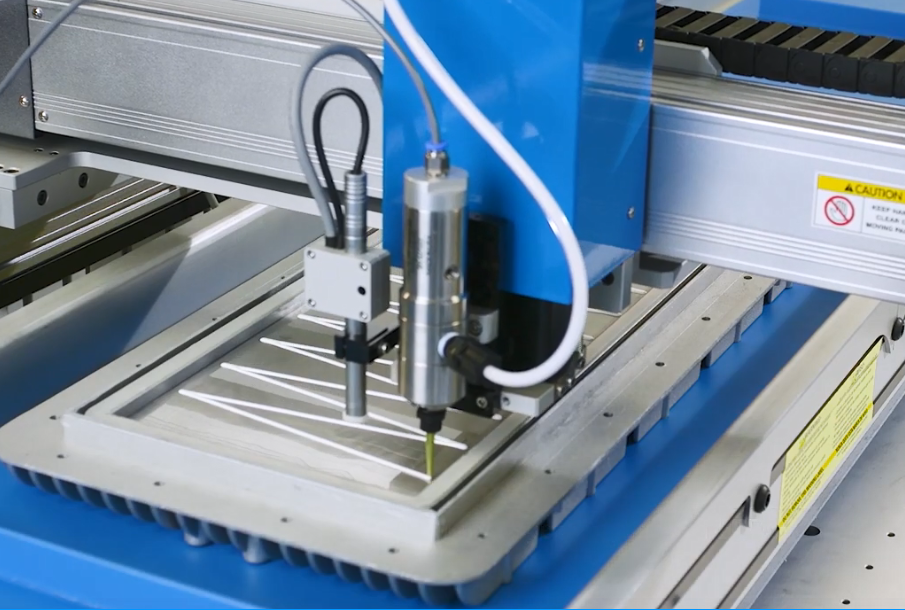

can automatically dispense glue according to their own process to improve production efficiency.

- Product Details

- {{item.text}}

Quick Details

-

EINECS No.:

-

/

-

Place of Origin:

-

Jiangsu, China

-

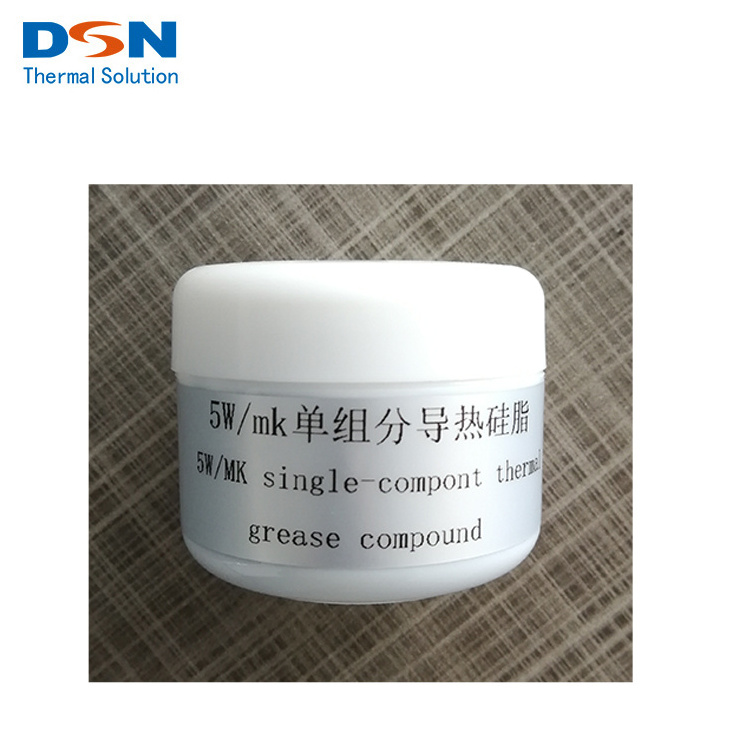

Brand Name:

-

DSN

-

Model Number:

-

HG200/HG350/HG500

-

Type:

-

Thermal insulation

-

Product name:

-

Thermal paste

-

Application:

-

Heat dissipation

-

Specific Gravity:

-

2.5~3.3 g/cm3

-

Thermal Conductivity:

-

2~5W/m.k

-

Volume Resistivity:

-

10^11

-

Application temperature:

-

-40~+150℃

-

Color:

-

Customized

-

Flammability:

-

UL94-VO

-

Certification:

-

ROHS

-

Feature:

-

High Temperature Resistance

Quick Details

-

CAS No.:

-

HG200/HG350/HG500

-

Other Names:

-

Thermal grease

-

MF:

-

/

-

EINECS No.:

-

/

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

DSN

-

Model Number:

-

HG200/HG350/HG500

-

Type:

-

Thermal insulation

-

Product name:

-

Thermal paste

-

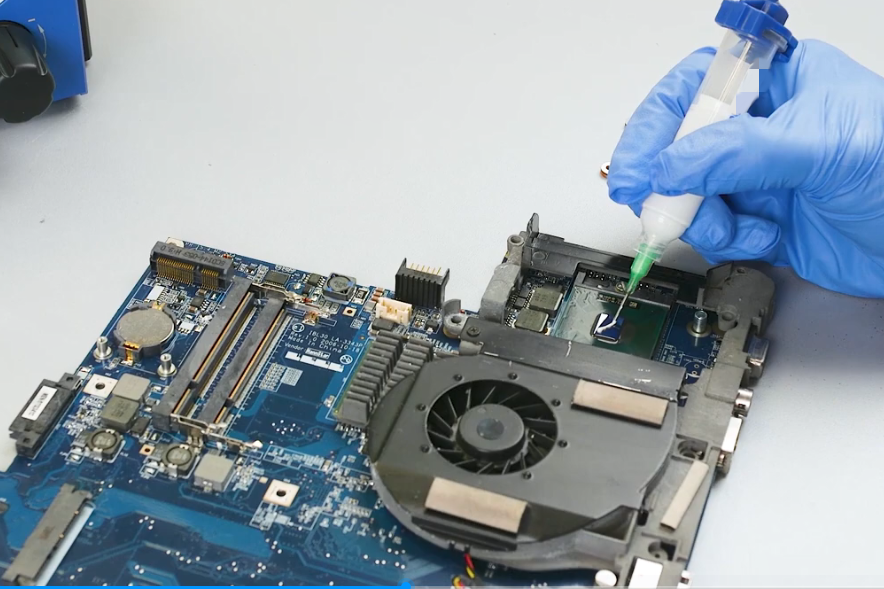

Application:

-

Heat dissipation

-

Specific Gravity:

-

2.5~3.3 g/cm3

-

Thermal Conductivity:

-

2~5W/m.k

-

Volume Resistivity:

-

10^11

-

Application temperature:

-

-40~+150℃

-

Color:

-

Customized

-

Flammability:

-

UL94-VO

-

Certification:

-

ROHS

-

Feature:

-

High Temperature Resistance

|

Product Name

|

Heat sink thermal conductivity silica gel

|

|

Material

|

Silicone

|

|

Function

|

Heat dissipation

|

|

Package

|

According to customer requirements

|

can automatically dispense glue according to their own process to improve production efficiency.

Parameters of Thermal conductive silicone gel

|

Typical properties

|

|

|

|

|

|

|

||||

|

Property

|

Value

|

|

|

|

|

Test method

|

||||

|

Item No.

|

HM400

|

HM700

|

HF200

|

HF350

|

HF600

|

|

||||

|

Composition

|

Silicone + ceramic/ graphene

|

Silicone + ceramic/ graphene

|

Silicone + ceramic/ graphene

|

Silicone + ceramic/ graphene

|

Silicone + ceramic/ graphene

|

−

|

||||

|

Color

|

Green

|

Gray

|

Yellow/white

|

Blue/white

|

Gray/white

|

Visual

|

||||

|

Min interface thickness (mm)

|

0.1

|

0.1

|

/

|

/

|

/

|

−

|

||||

|

Density (g/cc)

|

2.9

|

3.3

|

2.5

|

3.2

|

3.3

|

ASTM D792

|

||||

|

Specific heat capacity (J/g·K)

|

1.1

|

1.1

|

/

|

/

|

/

|

ASTM E1269

|

||||

|

Extrusion rate (g/min)

|

25

|

15

|

/

|

/

|

/

|

30cc tube, 0.130” needle, 90psi (621 kPa)

|

||||

|

Volatility (%)

|

<0.01

|

<0.01

|

<0.01

|

<0.01

|

<0.01

|

ASTM E595

|

||||

|

Temperature resistance (°C)

|

-50~200

|

-50~200

|

-50~200

|

-50~200

|

-50~200

|

−

|

||||

|

Electrical property

|

|

|

|

|

|

|

||||

|

Dielectric strength (Kv/mm)

|

≥5.0

|

>5.0

|

>5.0

|

>5.0

|

>5.0

|

ASTM D149

|

||||

|

Volume resistivity(Ω.cm)

|

1013

|

1013

|

1013

|

1013

|

1013

|

ASTM D257

|

||||

|

Fire rating

|

V-0

|

V-0

|

V-0

|

V-0

|

V-0

|

UL 94

|

||||

|

Thermal property

|

|

|

|

|

|

|

||||

|

Thermal conductivity (W/m-K)

|

4.0

|

7.0

|

2.0

|

3.5

|

6.5

|

ASTM D5470

|

||||

Why use the

Thermal conductive silicone gel

?

Natural graphite is sintered with flake graphite and earthy graphite, and its carbon content reaches 99% ~ 99.99%. Oriented film:

Graphite film using advanced technology to make high-purity graphite materials to regular orientation structure

Synthetic graphite sheet, also called artificial graphite sheet, is a new film material made of Polyimide by sintering. It is available with an adhesive backing on one side, which can significantly improve the thermal resistance.

Thermal conductive silicone pad is specially designed for the purpose of high performance thermal conductivity.

Pad standard size 400mm*200mm according to customer needs to cut the shapes. Basic thickness: 0.3 mm / 0.5mm/1mm/1.5mm / 2mm/ 3mm.

Dasen Culture

Enterprise mission: cultivate talents and make dedication.

Business idea: people-oriented, customer first, continuous creation, pursuit excellence.

Environmental policy: full participation, compliance with laws and regulations, treasure resources.

Q1: Do you have MOQ?

A1: No MOQ for the standard product.

Q2: Do you provide samples?

A2: Yes, we do, and could delivery in 24 hours after confirmation for stock.

And we can offer free samples within one pcs. Just please pay the shipping fee.

Q3: Are you factory or trading company

?

A3: No, we are a professional manufacturer for over 10 years.

Q4: What is the lead time for mass production?

A4: The lead time of mass production is about 5 - 7 days.

Q5: What is your payment method?

A5: Accept TT, Paypal, West Union, L/C, ect.

Q6: Can you provide finished product processing service?

A6: Yes, we can provide the finished product after die-cutting.