- Product Details

- {{item.text}}

Quick Details

-

Ultimate Strength (≥ MPa):

-

0.05-0.06

-

Density (kg/m³ ):

-

128

-

Length:

-

according to requirements

-

Working Temperature:

-

1050-1350

-

Fiber Diameter:

-

3.5

-

Shrinkage (1800 ℉, 3h):

-

-2.5

-

Thermal Conductivity:

-

0.09-0.22

-

Model Number:

-

1260

-

Brand Name:

-

Jucos

-

Place of Origin:

-

Shandong, China

-

Product Name:

-

Ceramic Fiber Blanket

-

Keyword:

-

Ceramic Fiber Blanket

-

Color:

-

Pure White

-

Product name:

-

Thermal Insulation ceramic fiber blanket

-

Refractory temperature:

-

1260C 1430C

-

ISO Certificate:

-

Available

-

Sample:

-

Available

Quick Details

-

Thickness:

-

6-50mm

-

Width:

-

610mm

-

Chemical Composition:

-

Al2O3+SiO2

-

Ultimate Strength (≥ MPa):

-

0.05-0.06

-

Density (kg/m³ ):

-

128

-

Length:

-

according to requirements

-

Working Temperature:

-

1050-1350

-

Fiber Diameter:

-

3.5

-

Shrinkage (1800 ℉, 3h):

-

-2.5

-

Thermal Conductivity:

-

0.09-0.22

-

Model Number:

-

1260

-

Brand Name:

-

Jucos

-

Place of Origin:

-

Shandong, China

-

Product Name:

-

Ceramic Fiber Blanket

-

Keyword:

-

Ceramic Fiber Blanket

-

Color:

-

Pure White

-

Product name:

-

Thermal Insulation ceramic fiber blanket

-

Refractory temperature:

-

1260C 1430C

-

ISO Certificate:

-

Available

-

Sample:

-

Available

Description Of Products

Ceramic fiber blanket is manufactured by refractory ceramic fibers, providing effective solutions to a wide range of thermal management problems. Utilizing our proprietary high output blowing and spinning techniques, these products supply superior insulating performance, flexibility and resilience.

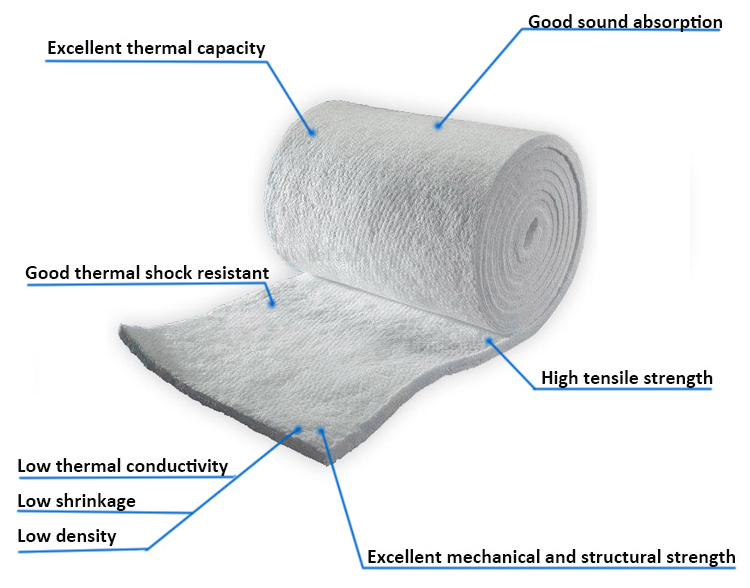

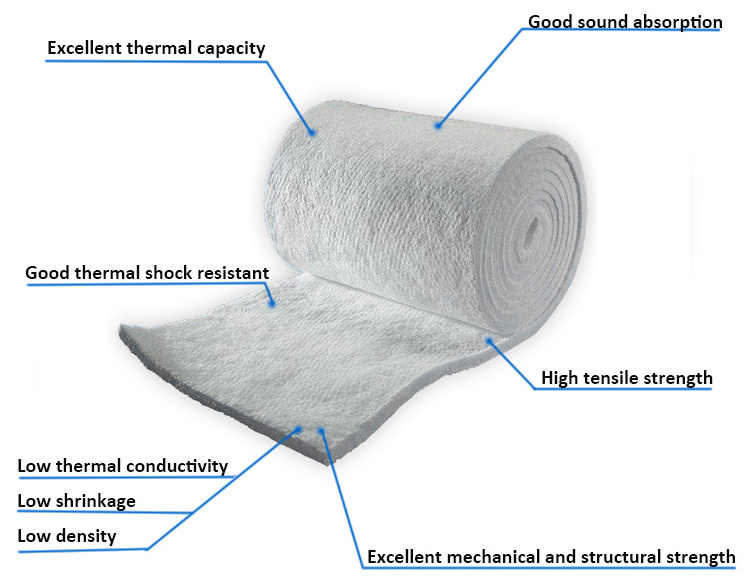

Features Of Product

High tensile strength

Excellent mechanical strength and structural strength

Low thermal conductivity, low shrinkage, low density

Excellent thermal capacity

Good sound absorption

Good thermal shock resistant

Applications Of Product

Annealing furnaces

Furnace door linings and seals

Soaking pit covers and seals

Furnace hot face repairs

Reheating furnace and ladle covers

Specifications Of Product

Alumina contents range from 40% to55%

Widely used throughout metallurgical industry

Physical And Chemical Indicators Of Product

|

Properties

Brand

|

|

ST BLT

|

GC BLT

|

HA BLT

|

HZ BLT

|

|

|

Specification Temp. (℃)

|

|

1260

|

1260

|

1360

|

1430

|

|

|

Working Temp. (℃)

|

|

1050

|

1100

|

1200

|

1350

|

|

|

Bulk Density (kg/m3)

|

|

96-160

|

96-160

|

96-160

|

96-160

|

|

|

(%)@24H Linear Shrinkage after Heating

|

|

-3

(1000℃)

|

-3

(1100℃)

|

-3

(1250℃)

|

-3

(1350℃)

|

|

|

(w/m.k) Thermal Conductivity

|

|

0.09(400℃)

0.176(800℃)

|

0.09(400℃)

0.176(800℃)

|

0.132(600℃)

0.22(1000℃)

|

0.76(600℃)

0.22(1000℃)

|

|

|

Tensile strength (MPa)

|

|

0.050

|

0.050

|

0.060

|

0.060

|

|

|

(%)

Chemical Composition

|

Al2O3

|

43

|

44

|

52

|

34

|

|

|

|

Al2O3+SiO2

|

96

|

98

|

99

|

-

|

|

|

|

Al2O3+SiO2+ ZrO2

|

-

|

-

|

-

|

99

|

|

|

|

ZrO2

|

-

|

-

|

-

|

15-17

|

|

|

|

Fe2O3

|

1.0

|

0.5

|

0.2

|

0.2

|

|

|

|

Na2O+K2O

|

0.5

|

0.3

|

0.2

|

0.2

|

|

Pictures Of Product

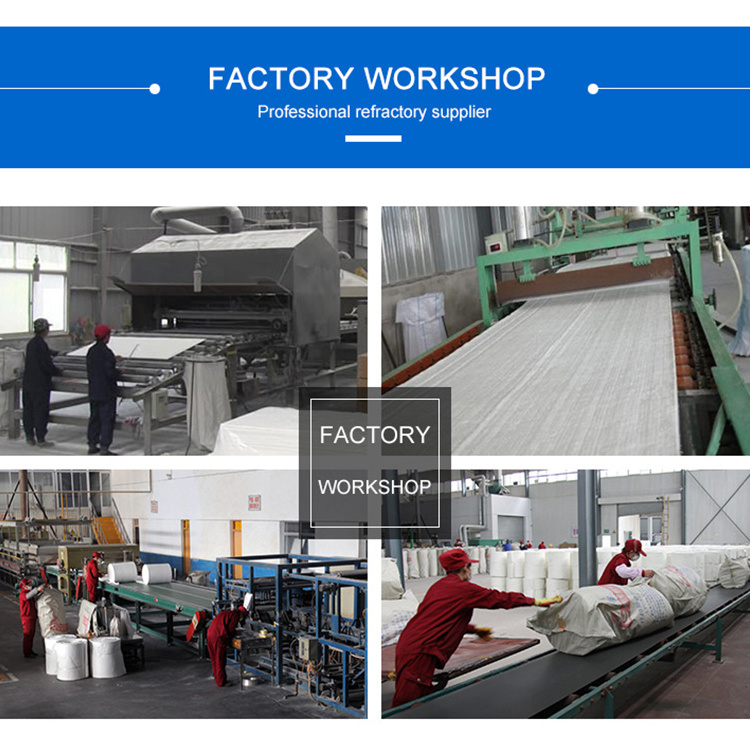

Laboratory Tour

Hot Searches