- Product Details

- {{item.text}}

Quick Details

-

Product name:

-

centrifugal disc polishing machine

-

Application:

-

Metal polishing

-

Function:

-

metal button grinding

-

Advantage:

-

High Efficiency Low Cost

-

Certification:

-

ISO CE

-

Keyword:

-

Finishing Machine

-

Voltage:

-

220v-460v

-

Feature:

-

High Efficiency

-

Machine type:

-

Metal Process Machine

Quick Details

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

HENGXING

-

Weight (KG):

-

1200

-

Product name:

-

centrifugal disc polishing machine

-

Application:

-

Metal polishing

-

Function:

-

metal button grinding

-

Advantage:

-

High Efficiency Low Cost

-

Certification:

-

ISO CE

-

Keyword:

-

Finishing Machine

-

Voltage:

-

220v-460v

-

Feature:

-

High Efficiency

-

Machine type:

-

Metal Process Machine

Product Description

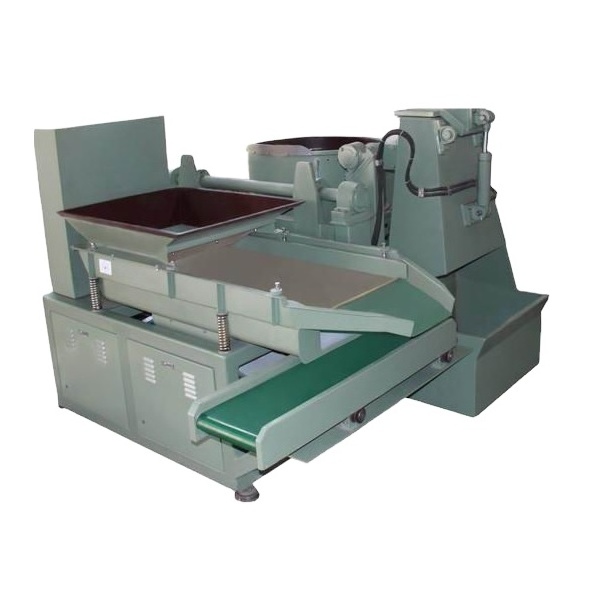

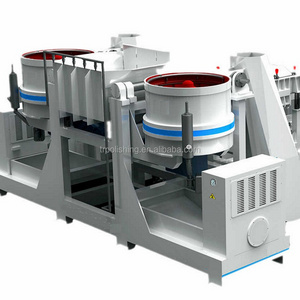

centrifugal disc polishing machine with speed control and separator

Centrifugal disk polishing machine are specially suitable for removal of strong burrs, intensive radiusing of small and

mid-size parts as well as gently smoothing and high gloss polishing.

Centrifugal disk polishing machine are specially suitable for removal of strong burrs, intensive radiusing of small and

mid-size parts as well as gently smoothing and high gloss polishing.

Adoption of centrifugal force theory to process the

workparts with improved efficiency of 15-30 times, Adjustable running speed of bottom disc, workparts can be randomly checked in the mass finishing process. Fixed upper barrel wall lined with good quality PU, it enjoys the better wear and long life cycle. In the process, the media and parts rise to the top of the load and then flow in toward the center and back down to the disc

Characteristics:

High speed processing allows for finishing performance up to 10 times faster than vibratory machine and over 20 times than barre machine. Infinitely adjustable speed of the spinner Low noise, movement smoothly and stably.

The working barrel is lined inside with hot poured, high wear-resistant polyurethane for protracting working life.

workparts with improved efficiency of 15-30 times, Adjustable running speed of bottom disc, workparts can be randomly checked in the mass finishing process. Fixed upper barrel wall lined with good quality PU, it enjoys the better wear and long life cycle. In the process, the media and parts rise to the top of the load and then flow in toward the center and back down to the disc

Characteristics:

High speed processing allows for finishing performance up to 10 times faster than vibratory machine and over 20 times than barre machine. Infinitely adjustable speed of the spinner Low noise, movement smoothly and stably.

The working barrel is lined inside with hot poured, high wear-resistant polyurethane for protracting working life.

|

Model

|

Capacity(L)

|

Size

L×W×H(mm) |

Motor (kw)

|

Weight (kg)

|

Speed (rpm)

|

Chamber dimension

(mm) |

PU thickness(mm)

|

|

WLM-60

|

60

|

1390×700×1240

|

1.5

|

400

|

0-180

|

460

|

22

|

|

WLM-120

|

120

|

1740×900×1470

|

4.0

|

600

|

0-160

|

640

|

26

|

|

WLM-230

|

230

|

1620×1008×1135

|

7.5

|

1100

|

0-140

|

800

|

30

|

Related Products

Hot Searches