- Product Details

- {{item.text}}

Quick Details

-

Frame of the project:

-

Q235 C section steel

-

Optional Roof:

-

EPS(polystyrene)/Rock wool sandwich panel tile

-

Optional Wall:

-

EPS(polystyrene)/Rock wool sandwich panel

-

Optional Door:

-

EPS sandwich panel door /Steel door /Plywood door /PVC door

-

Optional Window:

-

Aluminum alloy /PVC sliding window

-

Optional Floor:

-

Ceramic tile /Plywood /Composite wood board

-

Optional Ceiling:

-

Gypsum board /PVC ceiling /Aluminum ceiling

-

Foundation:

-

50mm-100mm thick Concrete foundation

-

Volume:

-

300m2-350m2/per 40ft HQ

-

Size:

-

As customer required

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Lixin

-

Model Number:

-

SS-PHS104

-

Frame of the project:

-

Q235 C section steel

-

Optional Roof:

-

EPS(polystyrene)/Rock wool sandwich panel tile

-

Optional Wall:

-

EPS(polystyrene)/Rock wool sandwich panel

-

Optional Door:

-

EPS sandwich panel door /Steel door /Plywood door /PVC door

-

Optional Window:

-

Aluminum alloy /PVC sliding window

-

Optional Floor:

-

Ceramic tile /Plywood /Composite wood board

-

Optional Ceiling:

-

Gypsum board /PVC ceiling /Aluminum ceiling

-

Foundation:

-

50mm-100mm thick Concrete foundation

-

Volume:

-

300m2-350m2/per 40ft HQ

-

Size:

-

As customer required

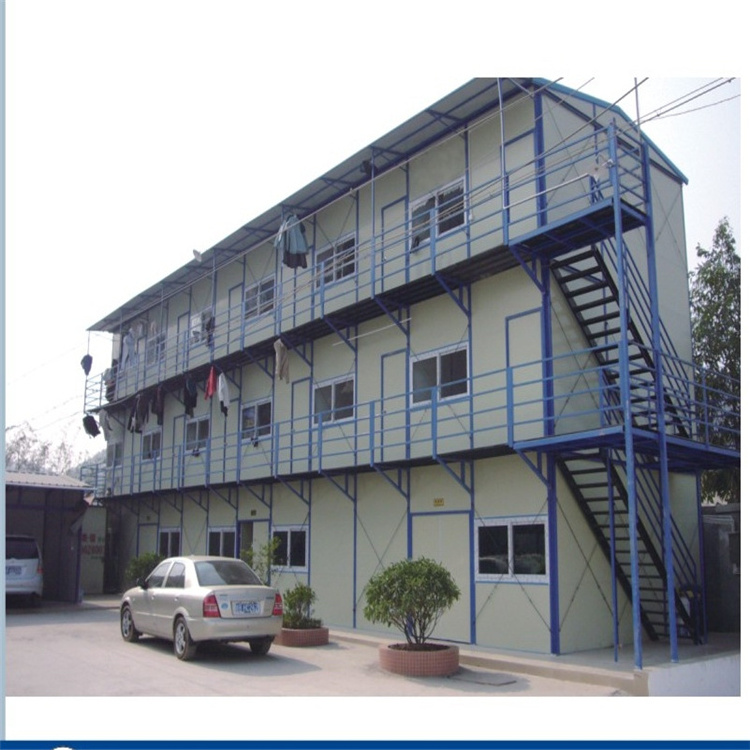

Reassembling Type Prefab House Instruction:

Lixin reassembling type prefab house is a kind of environmental friendly prefab house with a brand new

concept. It can be organized by modulization. The frame system is made by light steel structure and

the wall and roof system is made by sandwich panel. It realizes the temporary construction concept

as being simple and beautiful, fast installing, interchangeable and with safe and standard usage.

It’s a modular house product which can be industrialized produced, stored and repeated used.

Usage:

It is widely used in fieldwork as a temporary house such as the temporary office, meeting room,

headquarters, dormitory, shop, school, hospital, parking lot, exhibition hall, maintain station, gas

station at the construction site of road, railway, and municipal work and so on.

Characteristics:

Stable structure:

Light steel structure, safe and stable, can accord with the construction structure design standards.

Easy to Reassemble:

Can be used repeatedly. Only simple tools are needed during the installation.

20-30m2 can be finished each day by one worker.

Six worker can finished one 3K*10K standard prefab house.

Beautiful Appearance:

T he whole house is bright and colorful with soft texture, smooth surface.

Flexible Layout: The door and window can be located randomly and the partition wall can be put in any

position of the lateral axis. The stair can be put outside.

Water proof structure: The house is designed to be water-proof, no need for extra water-proof treatment.

Long lift span:

The light steel structure has be treated by the anti-rust spray.

It can be used for 10 years at least if used properly.

Environmental Friendly:

Reasonable design, easy to reassemble, can be repeatedly used, little wastage, no building

garbage. The average annual cost for using this type of house is much lower than the one made

by another material.

Multiple specifications:

The house are made of standard components, the length and width are both taking

K (1k=1820mm) as the modulus. The horizontal size is mK+160, vertical size is nK+160.

- Tie up the frame part together by steel wire with wood beam and cardboard; load into container by crane;

- The cladding part covered by transparent PVC for the surface of steel plate; load into container piece by piece.

- All material load into 20ft (HQ) or/and 40ft (HQ)

- As our experience, 20ft closed container can be load around 450-500 square meters sandwich panel, but depends on the container is flat enough and the length of the panels. 40ft closed container can load around 900-1000 square meters in the same situations.