- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

Depend on capacity

-

Product name:

-

HRSG Waste Heat Recovery Boiler System

-

Thermal efficiency:

-

75-85%

-

Capacity Range:

-

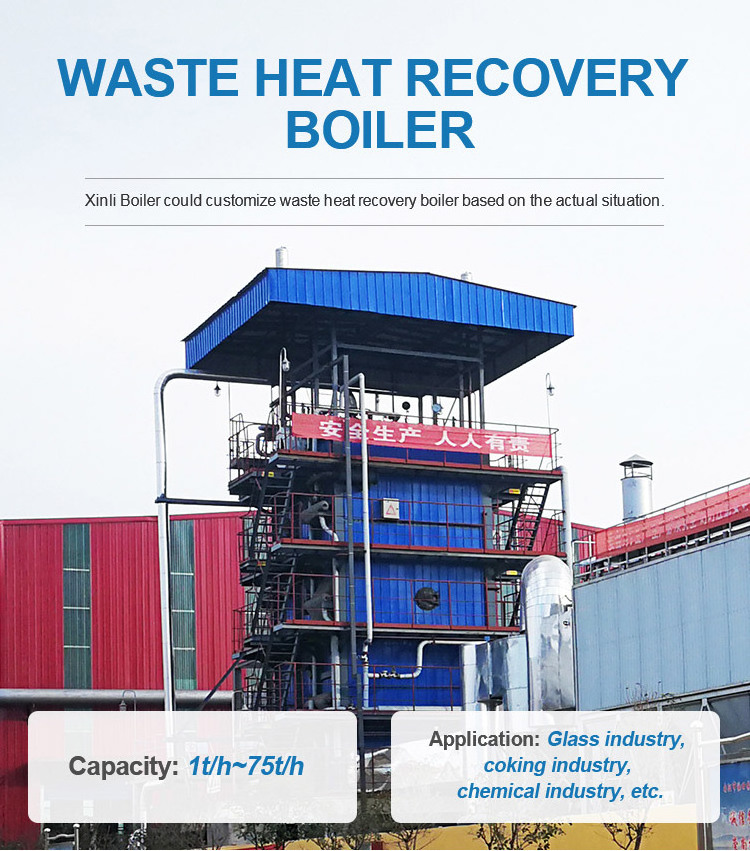

1t/h~75t/h

-

Applied Area:

-

Industry Waste Gas

-

Color:

-

Customer's Requirement

-

After Warranty Service:

-

Online support

Quick Details

-

Steam Production:

-

Max. 75t/h

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Xinli

-

Dimension(L*W*H):

-

Depend on capacity

-

Product name:

-

HRSG Waste Heat Recovery Boiler System

-

Thermal efficiency:

-

75-85%

-

Capacity Range:

-

1t/h~75t/h

-

Applied Area:

-

Industry Waste Gas

-

Color:

-

Customer's Requirement

-

After Warranty Service:

-

Online support

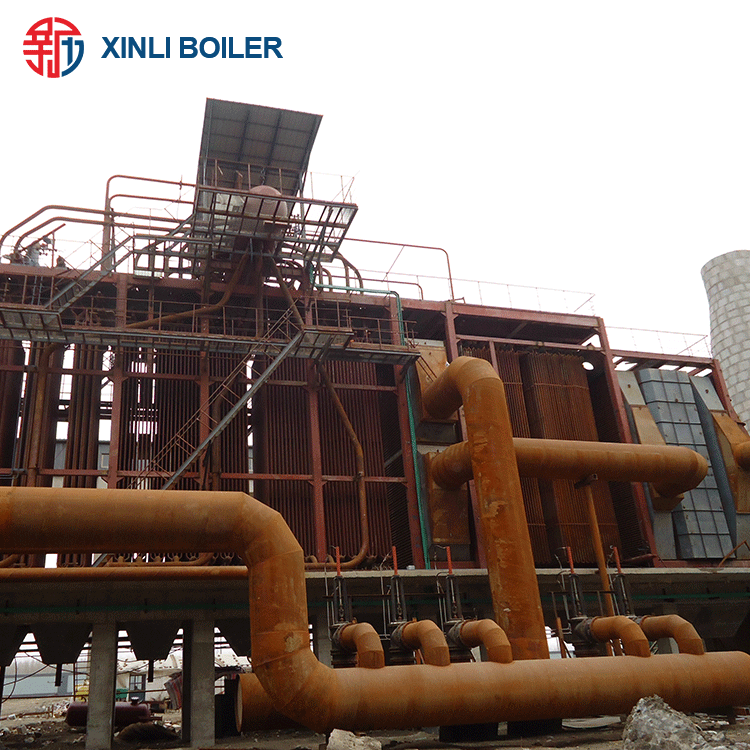

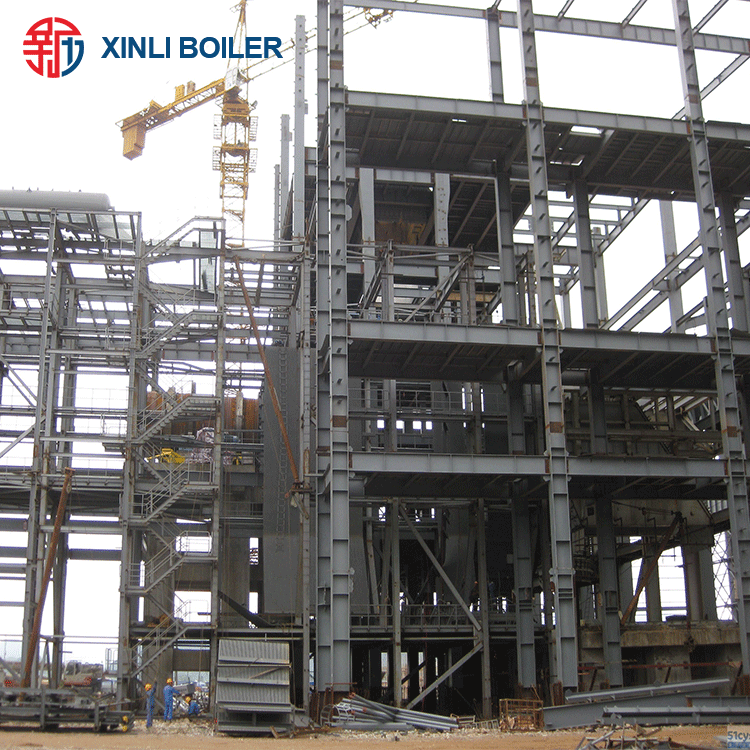

WHRB Exhaust Gas Boiler for Waste Heat Recovery System

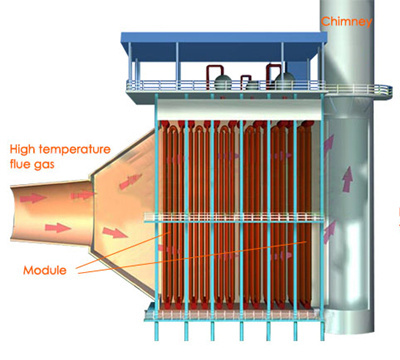

Exhaust gas boiler is the significant energy saving waste heat recovery system, it produces steam or hot water by utilizing the heat of exhaust gas, waste liquid during production process, also, it can use the heat of dynamic mechanical exhaust gas. The high temperature flue gas generated by waste material or waste liquid goes into the furnace of waste heat boiler, working medium inside of waste heat boiler will take it into the front and end smoke chamber in order, then high temperature flue gas become the low temperature flue gas discharged into the atmosphere by the chimney.

Main Waste Heat Boiler Types

1. Horizontal three wastes mixed burning blown gas waste heat water

2. Carbon rotary kiln waste heat boiler

3. Tank type carbon waste waste heat boiler

4. Coking waste heat boiler (after burning)

5. Hazardous waste incineration of waste heat boiler

6. CDQ waste heat boiler, glass kiln waste heat boiler

7. Sintering machine waste heat boilers, sulfuric acid heat boiler

8. Oil catalytic cracking of waste heat boiler

9. Non-ferrous metal smelting waste heat boiler

10. Steel smelting wate heat boiler

11. Pure low temperature waste heat boiler in cement kiln

12. Gas turbine waste heat boiler

We could design the boiler according to the user’s specific requirement.

Features:

1. Energy saving and reduce production cost

The boiler produces steam or hot water by utilizing the heat of exhaust gas or waste liquid during production process, do not need burn fuels, save energy.

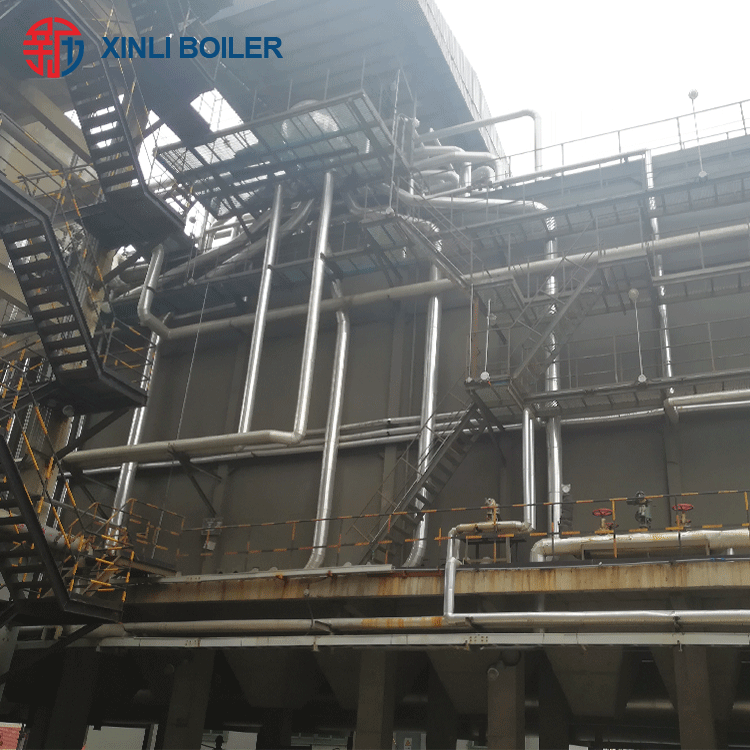

2. Compact structure, high thermal efficiency

Adopts acicular heat exchanger, the heat exchange area is 6~8 times of smooth-tube heat exchanger. All the welding line is automatic welding, and detected by X-rays to ensure the quality. The volume and weight is decrease, lower cost on boiler installation.

3. Anti-corrosion

Based on the different waste heat recovery boilers, Sitong boiler takes several measures to avoid the heating area is corroded by flue gas.

4. Environmental protection

According to the different waste gas, equipped with different dust remover or desulfurization equipment to meet the requirement of environmental protection.

|

Model |

Rated Evaporation Capacity (t/h) | Rated Pressure (MPa) | Steam Temperature (℃) | Exhaust Gas Temperature (℃) |

| Q11/950-4-2.5/400 | 4 | 2.5 | 400 | 190 |

| Q11/950-4-2.5/450 | 4 | 2.5 | 400 | 170 |

| Q11/900-4-2.5/400 | 4 | 2.5 | 400 | 155 |

| Q15/800-5-2.6/400 | 5 | 2.6 | 400 | 180 |

| Q15/800-5-2.6/400 | 5 | 2.6 | 400 | 180 |

| Q26.8/900-9.8-2.5/400 | 9.8 | 2.5 | 400 | 159 |

| Q38.2/930-15-2.5/400 | 15 | 2.5 | 400 | 148 |

| Q50/1100-25-2.5/400 | 25 | 2.5 | 400 | 150 |

| Q72/860-25-3.82/450 | 25 | 3.82 | 450 | 189 |

|

Note: Xinli Boiler could customize design the waste heat recovery boiler based on the actual demand |

||||