- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Xindacheng

-

Voltage:

-

Customized

-

Dimension(L*W*H):

-

30000mm 3000mm 3000mm

-

Power (kW):

-

110

-

Weight:

-

15000 KG

-

Name:

-

High Speed Internal Flat Dripper Irrigation Pipe Making Machine

-

After-sales Service 1:

-

Field installation, commissioning and training

-

After-sales Service 3:

-

Free Spare Parts ; Video/Online technical support

-

After-sales Service 2:

-

Field maintenance and repair service

-

Motor brand:

-

Siemens

-

Inverter brand:

-

Siemens, ABB

-

Contactor brand:

-

Siemens, Schneider, Omron

-

PLC control system:

-

Siemens

-

Touch screen:

-

Siemens, Schneider

-

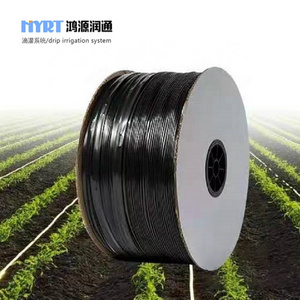

Final product:

-

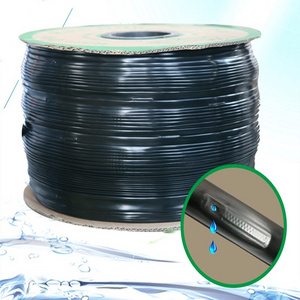

Internal Flat Dripper Irrigation Pipe

Quick Details

-

Screw Design:

-

Single-screw

-

Screw L/D Ratio:

-

38:1

-

Screw Speed (rpm):

-

130 rpm

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Xindacheng

-

Voltage:

-

Customized

-

Dimension(L*W*H):

-

30000mm 3000mm 3000mm

-

Power (kW):

-

110

-

Weight:

-

15000 KG

-

Name:

-

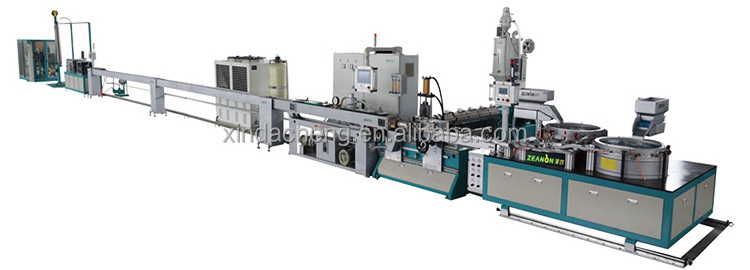

High Speed Internal Flat Dripper Irrigation Pipe Making Machine

-

After-sales Service 1:

-

Field installation, commissioning and training

-

After-sales Service 3:

-

Free Spare Parts ; Video/Online technical support

-

After-sales Service 2:

-

Field maintenance and repair service

-

Motor brand:

-

Siemens

-

Inverter brand:

-

Siemens, ABB

-

Contactor brand:

-

Siemens, Schneider, Omron

-

PLC control system:

-

Siemens

-

Touch screen:

-

Siemens, Schneider

-

Final product:

-

Internal Flat Dripper Irrigation Pipe

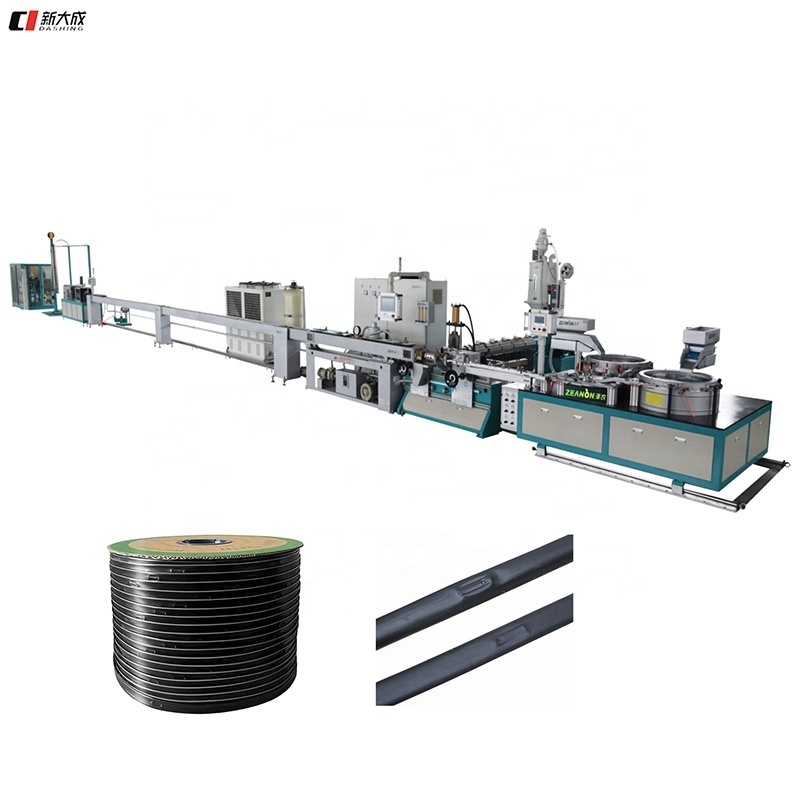

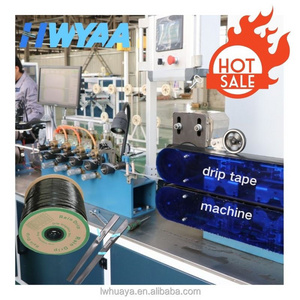

Product Overview

Farm Drip Irrigation System Inlaid Flat Irrigation Hose Making Machine

Plastic Tube Manufacturing Machine

(a) This production line is a project jointly promoted by Xindacheng, the European AAS Company and the

Water Conservancy and Hydropower Science Research Institute

.

(b)

It integrates European and Xindacheng technologies, has a high degree of automation, and has obtained 16 national patents (

Patent number:

2016203222198, 2010202279670, 201630270086X, 2018219396004, 2016208782834,2015107208626, 2020220367391, 2020231043358, 2015107244711, 2018219396447, 2022211667786, 2022232129355, 2016106409834, 2016208485221, 2013205244018, 2016109887611).

(c)

Using servo motor control, the stability, automation, convenience and precision functions are better.

We have stock in our factory, welcome to visit at any time.

|

Machine Model

|

Production Speed

|

Diameter

|

Thickness

|

Distance of Dripper

|

|

300A

|

300 m/min

|

φ12-16-20-25mm

|

0.12-0.9mm

|

100-1000mm

|

|

300B

|

400 m/min

|

|

|

|

PRODUCT CONFIGURATION

The whole production line consists of the following eight parts:

|

No

|

Item

|

Quantity

|

|

1

|

Automatic dripper screening inserting embedding device

|

1 set

|

|

2

|

Single screw extruder with automatic feeding system

|

1 set

|

|

3

|

Die head and dripper sticking device

|

1 set

|

|

4

|

Vacuum calibrating tank and water cooling tank

|

1 set

|

|

5

|

Full automatic punching device

Automatic online image monitoring analyzing and alarming system

Haul-off device

|

1 set

|

|

6

|

Accumulate device

|

1 set

|

|

7

|

Full automatic winding and roll changing system

|

1 set

|

|

8

|

PLC control system and cabinet

|

1 set

|

1. Automatic dripper screening inserting embedding device

A specially designed high-speed screening machine from Europe; equipped with a storage device; it can transport more than 3,000 drippers per minute.

2. Single screw extruder with automatic feeding system

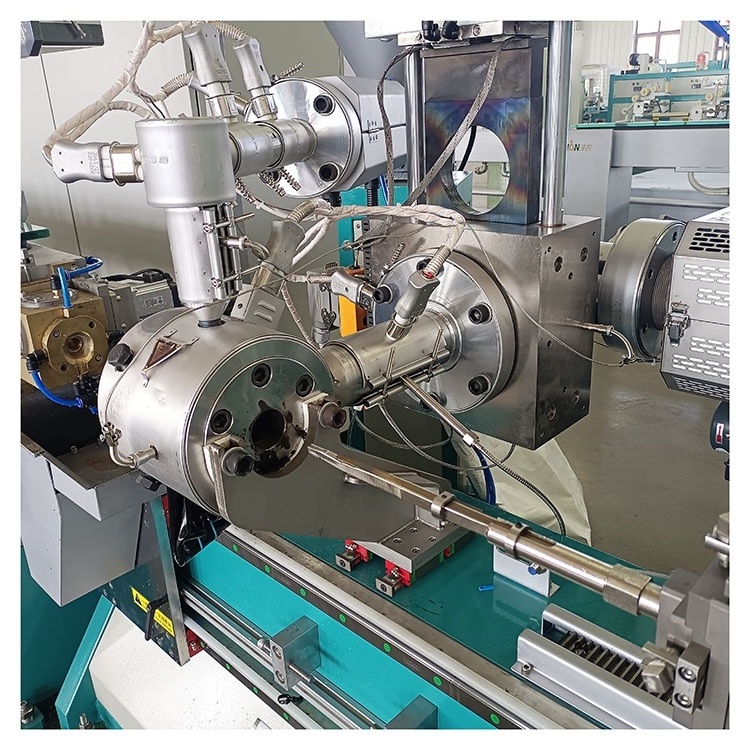

3. Die head and dripper sticking device

4. Vacuum calibrating tank and water cooling tank

5. Full automatic punching device;

Automatic online image monitoring analyzing and alarming system;

Haul-off device.

Haul-off device.

6. Accumulate device

7. Full automatic winding and roll changing system

FAQ

1.Are you manufacturer or trading company?

We are manufacturer.

2.Why choose us?

We have 30 years experience for producing machine.

3.Delivery time: 45~60 days.

4.Payment terms:

30% of total amount should be paid by T/T as down payment, the balance (70% of total amount) should be paid before delivery by T/T or irrevocable L/C(at sight).

5.After-sales service:

Free Spare Parts ;

We are manufacturer.

2.Why choose us?

We have 30 years experience for producing machine.

3.Delivery time: 45~60 days.

4.Payment terms:

30% of total amount should be paid by T/T as down payment, the balance (70% of total amount) should be paid before delivery by T/T or irrevocable L/C(at sight).

5.After-sales service:

Free Spare Parts ;

Field installation, commissioning and training ;

Field maintenance and repair service ;

Video/Online technical support.

6.Warranty: 1 year.

Field maintenance and repair service ;

Video/Online technical support.

6.Warranty: 1 year.

Hot Searches