- Product Details

- {{item.text}}

Quick Details

-

Air Pressure(MPa):

-

0.8 MPa

-

Sheet Thickness(mm):

-

0.2 - 3 mm

-

Heating Power (kW):

-

80 kW

-

Air Comsumption(L/min):

-

3000 L/min

-

Water Comsumption(L/min):

-

11.7 L/min

-

Place of Origin:

-

Henan

-

Brand Name:

-

Yugong

-

Voltage:

-

380V/50HZ

-

Dimension(L*W*H):

-

8450*2400*2600mm

-

Weight (T):

-

9 T

-

Product name:

-

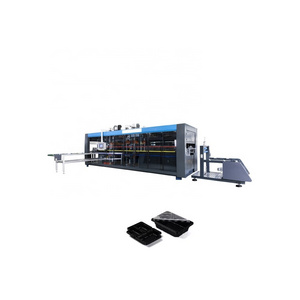

Fully Automatic PET Sheet Food Container Thermoforming Machines

-

Finished Products:

-

PET Vegetable Container

-

Sheet Thickness:

-

0.2 - 2 Mm

-

Function:

-

Making Disposable Container

-

Forming Area:

-

550*350mm

-

Suitable Sheet:

-

PVC PET PP POP PS

-

Model:

-

4 Pillar

-

Application:

-

Plastic Products

-

Color:

-

Customized Color

-

Marketing Type:

-

Hot Product 2020

Quick Details

-

Max.Forming Height(mm):

-

110 mm

-

Forming Width (mm):

-

550 mm

-

Forming Length (mm):

-

450 mm

-

Air Pressure(MPa):

-

0.8 MPa

-

Sheet Thickness(mm):

-

0.2 - 3 mm

-

Heating Power (kW):

-

80 kW

-

Air Comsumption(L/min):

-

3000 L/min

-

Water Comsumption(L/min):

-

11.7 L/min

-

Place of Origin:

-

Henan

-

Brand Name:

-

Yugong

-

Voltage:

-

380V/50HZ

-

Dimension(L*W*H):

-

8450*2400*2600mm

-

Weight (T):

-

9 T

-

Product name:

-

Fully Automatic PET Sheet Food Container Thermoforming Machines

-

Finished Products:

-

PET Vegetable Container

-

Sheet Thickness:

-

0.2 - 2 Mm

-

Function:

-

Making Disposable Container

-

Forming Area:

-

550*350mm

-

Suitable Sheet:

-

PVC PET PP POP PS

-

Model:

-

4 Pillar

-

Application:

-

Plastic Products

-

Color:

-

Customized Color

-

Marketing Type:

-

Hot Product 2020

Used Fully Automatic Plastic PET Sheet Food Container Thermoforming Machines For Sale

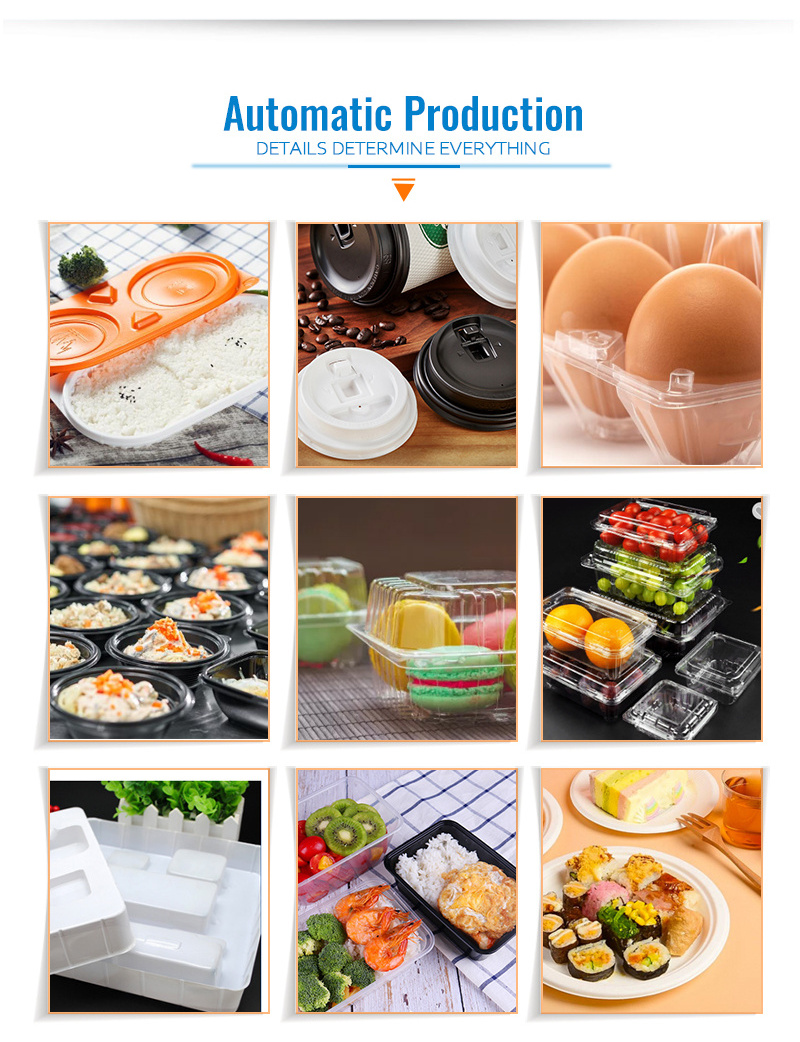

This plastic thermoforming machine is the latest core product developed by our company, integrated, punching, cutting, and stacking. It has a wide range of uses and is suitable for most customers' requirements. It can produce bowls, plates, various fast food boxes, packing boxes, supermarket trays, moon cake boxes, tofu boxes, biscuit boxes, etc. Stable operation, low noise, high efficiency and good quality.

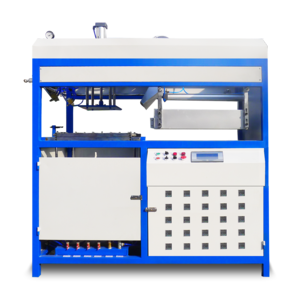

YUGONG Machinery Co.,Ltd specialized in ps foam thermoforming machinery.

it include:

1.PS foam thermocl tray/plate/dish making machine

2.PS foam food plate/ box making machine

3.PS disposable foam plate/tray/dish/ bowl making machine

4.take away food container production line

5.PS foam absorbent tray/plate/dish making machine

6.PS foam egg tray, wine tray making machine

7.PS foam hamburger box making machine

8.PS foam false ceiling machine

9.PS foam sheet extrusion line

|

Model

|

YG-550

|

|

Forming Area

|

550mm x 400 mm

|

|

Forming Depth (Max.)

|

100mm

|

|

Sheet thickness

|

0.2-2.0mm

|

|

Forming Speed (Max.)

|

30times/min

|

|

Air pressure

|

0.6-0.8mpa

|

|

Air consumption

|

3.0 m³/min

|

|

Water consumption

|

0.7 m³/h

|

|

Sheet width (Max.)

|

550mm

|

|

Suitable Sheet

|

PP, PS, HIPS, PET, PVC, PLA etc.

|

|

Power supply

|

AC 380V, 50Hz, Three-phase, Four-wire

|

|

Used power

|

50Kw

|

|

Rated power

|

100Kw

|

|

Heating power

|

75Kw

|

|

Procedure

|

Forming-cutting-stacking

|

|

Dimension

|

L9700*W4600*H2700mm

|

|

Weight

|

About 9.0T

|

|

MAIN ELECTRICAL COMPONENTS

|

|

|

PARTS

|

BRAND

|

|

Filter

|

CKD (Japan)

|

|

Forming valve

|

MAC (USA)

|

|

Temperature control module

|

WEST (UK)

|

|

Proximity switch

|

ROCKWELL (USA)

|

|

AC contactor\Circuit breaker\Button

|

SCHNEIDER (France)

|

|

Intermediate relay

|

IDEC (Japan)

|

|

Intermediate Relay Base

|

OMRON (Japan)

|

|

PLC\Touch screen\Servo motor\Air switch

|

Detla (Taiwan)

|

Forming,cutting, stacking are done in the same machine, saving labor, improving efficiency, lowing labor intensity and reducing production cost.

Production process is to put foam sheet into forming machine, and product wastage will come out from the rear part. Two workers are enough for the whole production line.

It can be used to produce many kinds of materials. Product can be used in the food, electronic parts, tourism, toys, etc.

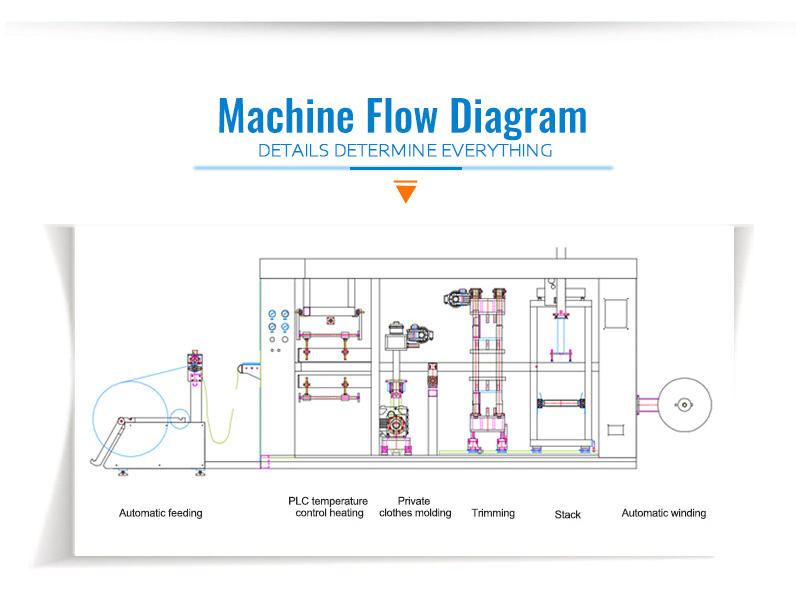

General Process

SUMMARY OF MACHINE

2. Feeding and heating part have optoelectronic switch in order to prevent error operating from production process.

3. The toothed chain made of 65#Mn, helping convey sheet. Aluminum rails with water cooling, save water.

4. The machine adopts PID temperature system, it shows high precision, and temperature control tolerance <1℃.

5. Each servo motor has overload protection for machine’s overworking.

6. Low barycenter and height of finished products as well as steady running ensures easy operation and friendly viewing. There is an alarm function of the sliding doors.