- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

Customized

-

Weight (T):

-

0.9 T

-

Power (kW):

-

45-160

-

Application:

-

Metal Melting

-

Applicable Metal:

-

Gold,Silver,Copper,Brass

-

Temperature:

-

1800℃

-

Heating Mode:

-

IGBT Induction Heating

-

Capacity:

-

50kg-250kg Brass

-

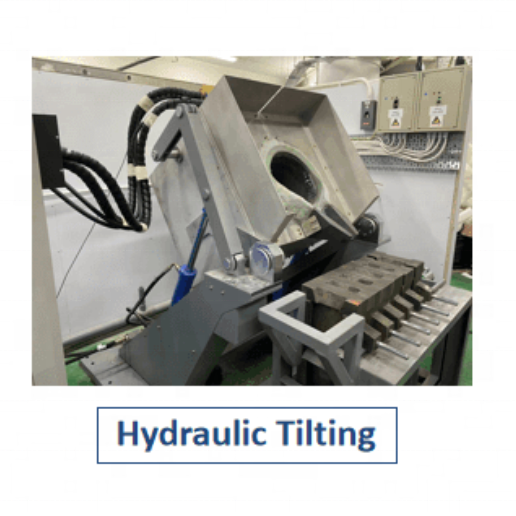

Tilting Mode:

-

Hydraulic tilting

Quick Details

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

CDOCAST

-

Voltage:

-

Customized

-

Dimension(L*W*H):

-

Customized

-

Weight (T):

-

0.9 T

-

Power (kW):

-

45-160

-

Application:

-

Metal Melting

-

Applicable Metal:

-

Gold,Silver,Copper,Brass

-

Temperature:

-

1800℃

-

Heating Mode:

-

IGBT Induction Heating

-

Capacity:

-

50kg-250kg Brass

-

Tilting Mode:

-

Hydraulic tilting

Products Description

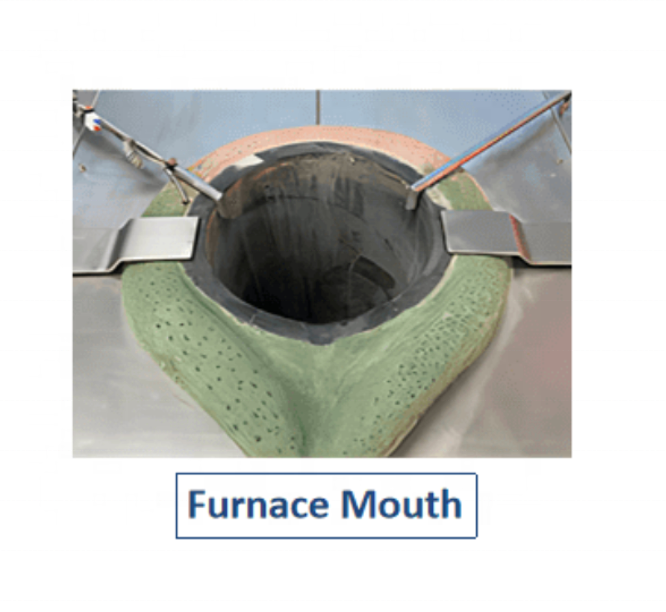

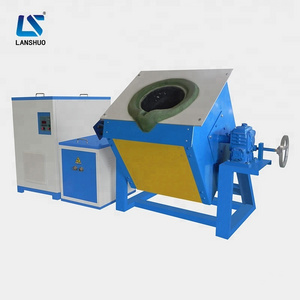

1800 Degree High Temperature Brass Induction Melting Furnace With Hydraulic Tilting For Sale

CDOCAST Brass Induction Melting Furnace

is a specialized equipment used for melting large amounts of metals such as Brass, gold, silver, and copper. It has IGBT power supply for induction heating, which can save approximately 30% of electrical energy compared to traditional resistance heating mode. Secondly, the load-bearing capacity of hydraulic system is stronger than that of mechanical transmission system such as chain tilting, making it more suitable for production projects that produce a large amount of metal per batch. The hydraulic oil can absorb heat to ensures that the furnace can operate for 24 hours without overheating. The accuracy of the hydraulic system is also very high, and users can achieve the operation of fine-tuning the tilt angle of the furnace. Customers can also choose to equip remote control and PLC systems, with just setting the parameters in advance, so one worker can complete all operations.

Feature:

1.

IGBT induction heating power supply can save 30% of electricity compared to resistance heating, making it suitable for production projects.

2.

The machine can work continuously for 24-hours.

3.

The hydraulic system has strong load-bearing capacity and high accuracy. Users can achieve fine adjustment of the angle when tilting the furnace.

4.

CDOCAST small induction furnace comes with Siemens touch screen design, the integrated power cabinet structure makes the whole operation more convenient & automatic. All functions are centralized in the PLC module and the entire melting process can be monitored in real time.

50KG Brass Hydraulic Small Induction Furnace

Parameter

|

Model

|

CDO-HT45

|

CDO-HT70

|

CDO-HT90

|

CDO-HT110

|

CDO-HT160

|

||||

|

Capacity(Brass)

|

50kg

|

80kg

|

120kg

|

150kg

|

250kg

|

||||

|

Max Input Power

|

45kw

|

70kw

|

90kw

|

110kw

|

160kw

|

||||

|

Max Input Current

|

68A

|

105A

|

135A

|

168A

|

240A

|

||||

|

Temperature

|

1800℃

|

|

|

|

|

||||

|

Input Voltage

|

Customized

|

|

|

|

|

||||

|

Oscillation frequency

|

1-20KHz

|

|

|

|

|

||||

|

Cooling Water

|

Water Pressure:≥0.3Mpa

|

|

|

|

|

||||

|

|

Flow rate:≥20L/Min

|

|

|

|

|

||||

|

|

Temperature:≤45℃

|

|

|

|

|

||||

Finished Product

Related Products

100-150kg Gold Hydraulic Melting Furnace (Aluminum Furnace Body)

250kg Gold Hydraulic Melting Furnace (Steel Furnace Body)

Chain Tilting Melting Furnace Manual Tilting Melting Furnace

Factory Photo

Customer Photos

Packaging & Shipping

FAQ

1. What is your advantage compared to others?

First, we provided turnkey solution, Cost-effective, highly efficient, durable, and easy-to-operate machine is what we

deliver.Second, we have a Strict Quality Control System, Before Being dispatched from our factory all of our equipment will

undergo a series of strict test, including the appearance quality test, voltage electrical test, aging test also the package strength checking.

2. If our machine meets fault, how could you help us to solve it?

For failures caused by using process, we will send our aftersales engineer to discuss with you, and you should provide the video of how the machine is broken, we will find out which part of the machine is broken, and then we will send you the broken part By DHL.

3. What is your warranty?

Our warranty period comes from the machine begin to run normally and we will provide the whole life technology support to you for free.All products sold by COOLDO/CDOCAST In the warranty period, we will provide you the spare parts for free. Our engineer will help you do the aftersales through our remote control system. When out of one year warranty time, we will provide the spare parts with the cost price for the whole machine lifetime.

Hot Searches