- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220V/380V

-

Dimension(L*W*H):

-

3200*1000*1500mm

-

Weight:

-

800 kg

-

Name:

-

Float fish food machine/ poultry feed machine

-

Application:

-

Fish Feed

-

Raw material:

-

Soybean Meal

-

Capacity:

-

180-250kg/h

-

Function:

-

Producing Animal Feeds Pellets

-

Motor:

-

Chinese Brand

-

Usage:

-

Animal Poultry Livestock Fish Feed Making Machine

-

Product name:

-

Fish Feed Pellet Machine

-

Color:

-

Selected

-

Key words:

-

Fish Pellet Machine

Quick Details

-

Max. Capacity:

-

1ton/h

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

MS

-

Voltage:

-

220V/380V

-

Dimension(L*W*H):

-

3200*1000*1500mm

-

Weight:

-

800 kg

-

Name:

-

Float fish food machine/ poultry feed machine

-

Application:

-

Fish Feed

-

Raw material:

-

Soybean Meal

-

Capacity:

-

180-250kg/h

-

Function:

-

Producing Animal Feeds Pellets

-

Motor:

-

Chinese Brand

-

Usage:

-

Animal Poultry Livestock Fish Feed Making Machine

-

Product name:

-

Fish Feed Pellet Machine

-

Color:

-

Selected

-

Key words:

-

Fish Pellet Machine

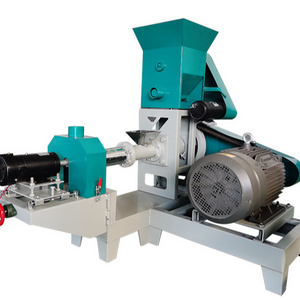

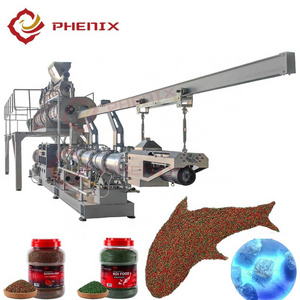

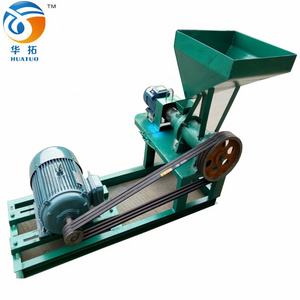

Floating fish feed extruder/fish food extruder machine for sale

Detailed introduction of floating fish feed extruder/fish food extruder machine for sale

1. Floating fish food machine/ poultry feed machine fish meal machine for sale, also known as fish feed pellet machine, is used to process various kinds of grains into high-grade aquatic feed pellets for fish, crab, catfish, shrimps, etc.

2. This floating fish feed extruder machine has gained popularity in fish farmers.

3. This floating fish feed pellet extruder machine is suitable for small and medium aquatic farm or feed pellets processing factory.

4. Compared with buying fish feed, making your own fish feed pellets by the floating fish feed extruder machine is really cost effective.

5. Aquaculture feed pellets have wonderful taste and high nutrition.

6. The size of pellet aquaculture feed made by this floating fish feed extruder can be adjusted according to your need.

Features of the floating fish feed extruder/fish food extruder machine for sale

1. Novel design, high output and stable performance.

2. Main parts are made of special alloy material after heat treatment.

3. High wear resistant degree and long service time.

4. This dry type floating fish feed extruder machine is suitable for small fish feed plant and professional farmers.

5. Final processed aquatic feed pellets have unique taste and high nutritious.

6. Low energy cost, high capacity, easy to maintain.

7. Diameters and shapes of fish pellets can be adjusted by choosing different molds.

8. Salmonellas and bacterial infections can be killed by high temperature and high pressure process.

9. Feed pellets produced by this aquaculture feed pellet making machine of puffing type, thus making it more easily to digest for fishes.

Specification of floating fish feed extruder/fish food extruder machine for sale

|

Model |

Capacity |

Main power |

Feeding power |

Screw diameter |

Cutting power |

|

MS-DGP50 |

0.06-0.08t/h |

11kw |

0.4kw |

φ50mm |

0.4kw |

|

MS-DGP60 |

0.12-0.15t/h |

15kw |

0.4kw |

φ60mm |

0.4kw |

|

MS-DGP70 |

0.18-0.25t/h |

18.5kw |

0.4kw |

φ70mm |

0.4kw |

|

MS-DGP80 |

0.3-0.35t/h |

22kw |

0.4kw |

φ80mm |

0.6kw |

|

MS-DGP90 |

0.4-0.45t/h |

37kw |

0.4kw |

φ90mm |

1.5kw |

|

MS-DGP120 |

0.5-0.7t/h |

55kw |

0.4kw |

φ120mm |

2.2kw |

|

MS-DGP135 |

0.8-1.0t/h |

75kw |

0.4kw |

φ133mm |

2.2kw |

|

MS-DGP160 |

1.2-1.5t/h |

90kw |

0.75-1.1kw |

φ155mm |

3.0kw |

|

MS-DGP200 |

1.8-2.0t/h |

132kw |

1.5kw |

φ195mm |

3.0-4.0kw |

Packing and delivery of floating fish feed extruder/fish food extruder machine for sale

1. Packing is in export wooden case packing or in bulk according to the size of the floating fish feed extruder machine.

2. we will make the floating fish feed extruder machine as quickly as possible after the cusomer playing the order, also with high capacity. we will track the shipping for customer whenever they need.

1. We will give detailed introduction of the floating fish feed extruder machine according to the client capacity requirement.

2. Share any information about the floating fish feed extruder machine that the clients need, like detaield pictures, video,etc

3. Design floating fish feed line for client.

4. Help the clients to do suitable floating fish feed formulation.

5. Give detailed instruction manual and video to help the client operation the floating fish feed extruder machine.