- Product Details

- {{item.text}}

Quick Details

-

CaO Content (%):

-

0.34%

-

CrO Content (%):

-

0.002%

-

SiC Content (%):

-

85% Min

-

Place of Origin:

-

Henan, China

-

Model Number:

-

HT-SCFD

-

Brand Name:

-

HT

-

Color:

-

Black

-

Size:

-

Customers' Requirement

-

BULK DENSITY:

-

2.6

Quick Details

-

SiO2 Content (%):

-

0.3-15

-

Al2O3 Content (%):

-

0.2

-

MgO Content (%):

-

0.8-1.2

-

CaO Content (%):

-

0.34%

-

CrO Content (%):

-

0.002%

-

SiC Content (%):

-

85% Min

-

Place of Origin:

-

Henan, China

-

Model Number:

-

HT-SCFD

-

Brand Name:

-

HT

-

Color:

-

Black

-

Size:

-

Customers' Requirement

-

BULK DENSITY:

-

2.6

SiC bushing sleeves have the characteristics of high flexing strength at elevated temperatures, high thermal shock resistance. High corrosion resistance and high thermal conductivity, high resistivity against alkalis.

Pressureless sintered silicon carbide with high heat conductivity, thermal shock stability is outstanding. Compared with the reaction sintered silicon carbide, it has better wear resistance, chemical corrosion resistance, and higher temperature resistance and PV value. It has been widely used in the field of petroleum, chemical industry, automobile industry, papermarking, printing and dyeing, sewage treatment, and especially used in high requirements of the food, pharmaceutical, nuclear industry and other industries.

Specially shaped silicon carbide ceramic parts can also be produced according to customers’ requirements and drawings. Relying on powerful technical ability and normative quality management system, we can provide stable and precise silicon carbide parts and offer the best service to the customer.

SiC silicon carbide production lines:

1. Reaction Sintered Silicon carbide (RSSIC)

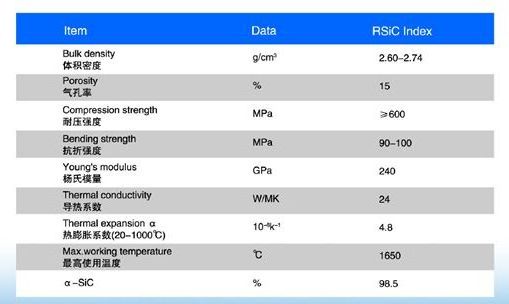

2. Recrystallized Silicon Carbide ceramic (RSiC)

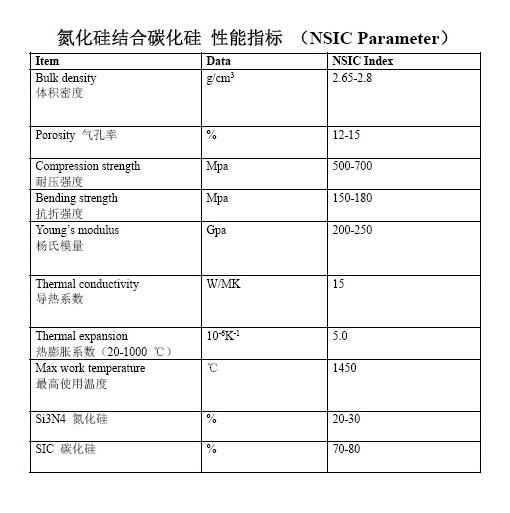

3. Nitride Bonded Silicon Carbide ceramic (NbSiC)

4. Hot Pressed Silicon Carbide ceramic (HPSC)

5. Sintered Silicon Carbide ceramic (SSIC)

|

Project |

Unit |

SSic |

|||

|

Volume density |

g/cm3 |

3.10-3.15 |

|||

|

Hardness |

HRA |

≥ 92 |

|||

|

Compressive strength |

MPa |

≥ 2200 |

|||

|

Flexural strength |

MPa |

≥ 400 |

|||

|

Silicon carbide content |

% |

≥ 98 |

|||

|

Modulus of elasticity |

Gpa |

400 |

|||

|

Thermal conductivity |

W/m.k |

100-200 |

|||

|

Surface blowhole defects |

Surface area (cm2) |

≥5 |

5-10 |

10-30 |

>30 |

|

To allow (a) the number of pore |

1 |

2 |

3 |

5 |

|

|

pore size (mm) |

<0.1 |

||||

Applications

· Mechanical seals, sliding bearings

· Shaft protection sleeves

· Ball bearings

· Isolation shells for magnetic pumps

· Pump wheels

· Pump shafts, nozzles

· Pipe linings