- Product Details

- {{item.text}}

Quick Details

-

Rolling thinckness:

-

0.3-1mm

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

CHBEST

-

Voltage:

-

380V 50Hz 3phases

-

Dimension(L*W*H):

-

6m*1.2m*1.4m

-

Weight:

-

4T

-

Warranty:

-

2 Years

-

Product name:

-

Zinc Metal Cold Shutter Door Roll Forming Machine Manufacturer

-

Raw material:

-

Steel plate

-

Control system:

-

PLC(imported Brand)

-

Roller material:

-

45# Forged Steel

-

Cutting blade material:

-

Cr 12 Steel

-

Usage:

-

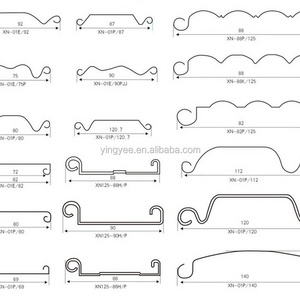

European type Door

-

Cutting type:

-

Hydraulic Cutting

-

Warranty time:

-

1 year

-

Color:

-

Client's Request

-

Technical support:

-

The whole life time

-

Certification:

-

CE, BV

Quick Details

-

Type:

-

Tile Forming Machine

-

Tile Type:

-

Steel

-

Production Capacity:

-

7-15M/MIN

-

Rolling thinckness:

-

0.3-1mm

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

CHBEST

-

Voltage:

-

380V 50Hz 3phases

-

Dimension(L*W*H):

-

6m*1.2m*1.4m

-

Weight:

-

4T

-

Warranty:

-

2 Years

-

Product name:

-

Zinc Metal Cold Shutter Door Roll Forming Machine Manufacturer

-

Raw material:

-

Steel plate

-

Control system:

-

PLC(imported Brand)

-

Roller material:

-

45# Forged Steel

-

Cutting blade material:

-

Cr 12 Steel

-

Usage:

-

European type Door

-

Cutting type:

-

Hydraulic Cutting

-

Warranty time:

-

1 year

-

Color:

-

Client's Request

-

Technical support:

-

The whole life time

-

Certification:

-

CE, BV

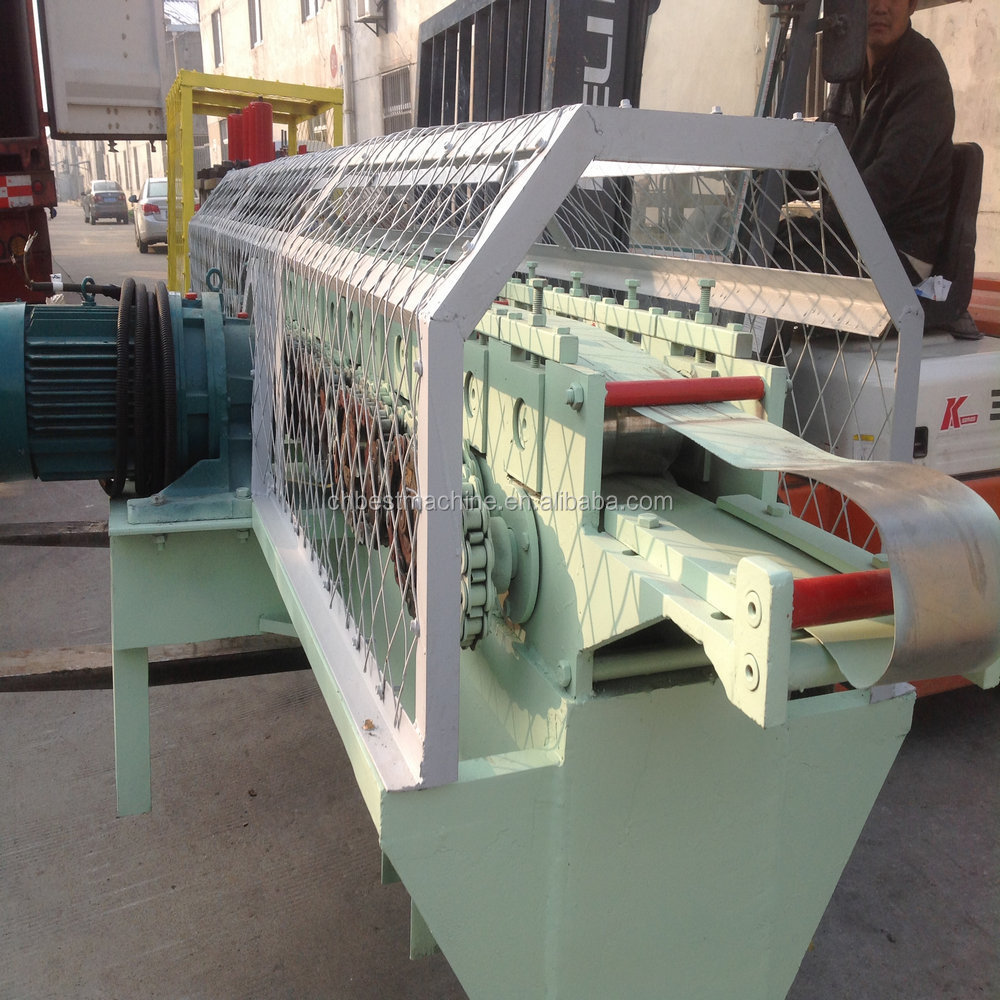

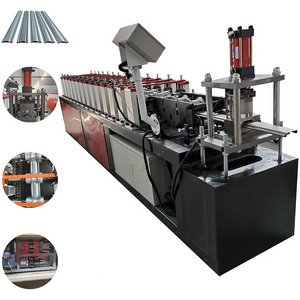

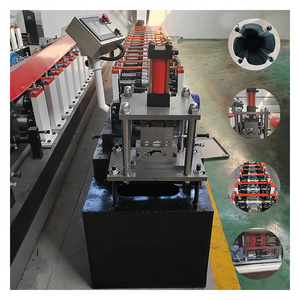

Galvanized Zinc Metal Cold Shutter Door Roll Forming Machine Manufacturer

Working flow:

Decoiler-----feeding------roll forming ------ punching-----cutting----output table

Machine components:

|

No. |

Name |

Qty |

|

1. |

De-coiler |

1 Set |

|

2. |

Roll Forming Machine |

1 Set |

|

3. |

Punching device |

1Set |

|

4. |

Hydraulic Cutting Device |

1 Set |

|

5. |

PLC Control Box |

1 Set |

|

6. |

Output table |

1 Set |

Technical Parameters

|

Material specification |

Galvanized and pre-painted galvanized steel. |

|

Thickness |

0.3 mm to 0.7mm. |

|

Main motor power |

5.5 kw. |

|

Hydraulic station power |

3 kw. |

|

Feeding width |

124mm. |

|

Cover width |

60mm. |

|

Yield stress |

235Mpa(33KSI) ~ 345Mpa (50KSI). |

|

Roll forming Speed |

12 m/minute. |

|

Cutting Tolerance |

±2mm |

|

Manual Uncoiler |

Max. Capacity: 5000kgs. |

|

Voltage |

As per customer’s request. |

|

Numbers of stands |

11 stands/stations/pairs. |

|

Roller material |

5# steel polished and coated with chrome HRC55-60° |

|

Shaft diameter |

70mm |

|

Shaft diameter |

high grade No.45 steel after treatment |

|

Type of cutting |

Roll-formed and length-set profile cutting. |

Terms

Payment type: 35% T/T prepaid and balance should be paid before loading

Delivery time: 30days after receving advance payment

Guarantee period: 24monthes free service/ pay service all the machine life

Installation and training: If buyers visit our factory and check the machine, we will teach you how to install and use the machine, and also train your workers/technician face to face.Without visiting,we willsend you user manual andvideo to teach you to install and operate.If buyer needs our technician to go to your local factory,please arrange board and lodging and other necessary

1. Are you manufacturer?

Yes, we are manufacturer and trading company.

2. What information you need before quote me?

We need profile drawin gof the panel you want to produce, material information and your special requirements

3. What payment terms you accept?

Commonly is TT, 30% deposit and 70% before shipment, and sometimes we can consider more for you as per your request

.

4. Can you make machine according to my design?

Yes, we have experienced technical team to work out the suitable design for you and confirm with you until you agree.

5. What is the warranty for our machine?

We have TWO years guarantee, and provide whole life's technical support

6. Is there any spare part send for free?

Yes, pls contact us we can talk it

7.Is the machine automatic?

Yes, it can be manual and automatic

8. Any more questions pls click "send inquiry" we can talk by email, thanks

We thank you for visiting our website, and we wish you a happy day. Good luck!