- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

IVEN

-

Weight (KG):

-

2000

-

Product name:

-

Normal Saline Soft Bag IV Solution Production Line

-

Capacity:

-

5800~6500 bags/ hour

-

Bag-making Film:

-

NON-PVC Film,Single port, Heat insulation sealing

-

Specification:

-

100ml,250ml, 500ml.1000ML

-

Power:

-

32KW

-

Dimension:

-

9.6m*2.4m*2.2m(L*W*H)

-

Voltage:

-

380V 50HZ

-

Type:

-

Filling Equipment

-

After-sales Service Provided:

-

Field maintenance and repair service,Video technical support

Quick Details

-

Production Capacity:

-

customized

-

Automatic Grade:

-

automatic

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

IVEN

-

Weight (KG):

-

2000

-

Product name:

-

Normal Saline Soft Bag IV Solution Production Line

-

Capacity:

-

5800~6500 bags/ hour

-

Bag-making Film:

-

NON-PVC Film,Single port, Heat insulation sealing

-

Specification:

-

100ml,250ml, 500ml.1000ML

-

Power:

-

32KW

-

Dimension:

-

9.6m*2.4m*2.2m(L*W*H)

-

Voltage:

-

380V 50HZ

-

Type:

-

Filling Equipment

-

After-sales Service Provided:

-

Field maintenance and repair service,Video technical support

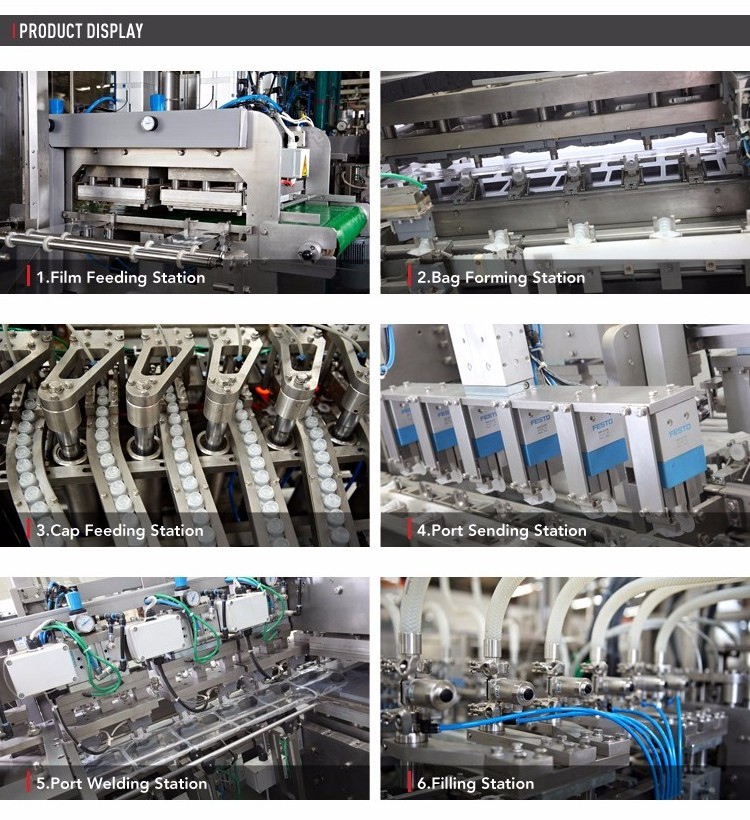

Pharmaceutical IV Infusion Soft Bag Filling Machine Production Line is the latest production line with most advanced technology. It can automatically finish film feeding, printing, bag making, filling and sealing in one machine.

This LVP FFS line can be used to automatically fill 50-5000ml general solution, special solution, dialysis solution, Parenteral nutrition, Antibiotics, Irrigation and Disinfectant solution etc.

IVEN can supply you different PP bag design with single boat type port, single/double hard ports, double soft tube ports etc.

Main features:

1.100% film utilization: No waste edge between bags, reducing both material and energy consumption.

2.Special IV bag design: each bag saves 10mm film than others.

3.Reliable heating and welding system: Leakage rate less than 0.03%.

4.Quick changeover: 0.5-1 hour to switch from one size to another.

5.Stable transmission system: only needs 1 control system, 1 HMI and 1 operator.

6.Safe filling nozzle: No solution overflows, no particles generation.

7.Auto faulty rejection system detected by the machine.

8.Production line length is reduced by 1/3, both workshop and air conditioning and cleaning area are reduced by 1/3, greatly reducing the initial investment and future running cost.

9.Simple structure, more stable and reliable performance.

Technical Parameter:

| Item | Main Content | |||||

|---|---|---|---|---|---|---|

| Model | SRD1A | SRD2A | SRD3A | SRD4A | SRD6A | SRD12A |

| Max. ACTUAL Production Capacity | 1000BPH | 2200BPH | 3200BPH | 4000BPH | 5500BPH | 10000BPH |

| Bag Size | 100ml, 250ml, 500ml, 1000ml (other specifications can be customized.) | |||||

| Power Supply | 3P/380V/50Hz | |||||

| Power | 8KW | 22KW | 26KW | 32KW | 32KW | 60KW |

| Nitrogen | According to special requirements, nitrogen protection is applicable | |||||

| Overall Size |

3.26x2.0

x2.1M |

4.72x2.6

x2.1M |

5.52x2.7

x2.1M |

6.92x2.6

x2.25M |

8.97x2.7

x2.25M |

8.97x4.65

x2.25M |

| Weight | 3T | 4T | 5T | 6T | 8T | 12T |