- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V, Local Voltage Requirements

-

Dimension(L*W*H):

-

2040X1470X1740

-

Weight:

-

500 kg

-

Application:

-

Sieve for finished feeds pellets

-

Capacity:

-

4-20ton/h

-

Power:

-

0.25KWx2

-

Function:

-

screening and classifying mash or pellet feed

-

Feature:

-

Low vibration and low noise

Quick Details

-

Max. Capacity:

-

20 ton/h

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

LONGTAI

-

Voltage:

-

380V, Local Voltage Requirements

-

Dimension(L*W*H):

-

2040X1470X1740

-

Weight:

-

500 kg

-

Application:

-

Sieve for finished feeds pellets

-

Capacity:

-

4-20ton/h

-

Power:

-

0.25KWx2

-

Function:

-

screening and classifying mash or pellet feed

-

Feature:

-

Low vibration and low noise

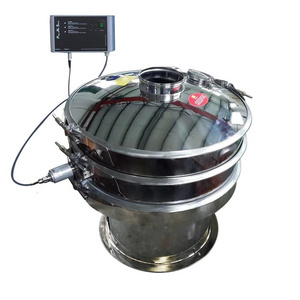

High Efficiency finished animal feeds Vibrating Screen Machine Sieve Machine Animal pellet feed flour vibrating screen sieve

Finished feed cleaning sieve: Your feed mill's efficient, precise, and worry-free screening assistant

Imagine running a feed mill where daily tasks include screening large quantities of finished feed. Traditional manual screening is inefficient and prone to errors that can affect feed quality. That's where an efficient, precise, and worry-free screening assistant - a finished feed cleaning sieve - comes in.

The finished feed cleaning sieve utilizes advanced sieving technology to quickly and accurately screen out feed that meets standards, greatly improving production efficiency. It can also effectively remove impurities from the feed to ensure its quality and safety. This screening assistant is perfect for use in feed mills, especially when large-scale, fast, and precise screening of feed is required.

Using a finished feed cleaning sieve, you can enjoy the following benefits:

Increased efficiency: Screening speed is faster, greatly shortening the production cycle and improving production efficiency.

Quality assurance: Advanced sieving technology effectively removes impurities, ensuring feed quality.

Cost savings: Reducing manual screening errors, reducing feed waste, and saving production costs.

Enhanced competitiveness: High-quality feed meets market demands and enhances the competitiveness of your feed mill.

In summary, the finished feed cleaning sieve is an efficient, precise, and worry-free screening assistant suitable for use in feed mills. It can not only help you improve production efficiency, ensure feed quality, but also save costs and enhance competitiveness. Let your feed mill stand out in the fierce market competition and become a leader in the industry!

Performance characteristics ,

Using a vibration motor, with low vibration and low noise; The streamlined design inside the discharge port prevents material deposition and avoids cross infection; The screen pressing mechanism is simple and allows for quick screen replacement

Application,

The SFJZ series vibrating grading screen is mainly used for screening and grading granular feed in feed factories, and can also be used for initial cleaning of raw materials in feed factories. In addition, it can also be widely used for screening and grading raw materials and finished products in various industries such as grain, food, chemical, sugar making, mining, and papermaking

Technical Parameter ,

| Model | SFJZ80X1 | SFJZ100X1 | SFJZ120X1 | SFJZ120X2 |

| Power(kw) | 0.37 | 0.37 | 0.5 | 0.5 |

| Capacity(t/h) | 4-12 | 6-15 | 8-18 | 10-20 |