- Product Details

- {{item.text}}

Quick Details

-

Weight (KG):

-

350

-

Voltage:

-

220v

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

JIN HUA TAI

-

Dimension(L*W*H):

-

700*1200*1700 mm

-

Machine Type:

-

Automatic Vertical Packaging Machine VFFS

-

Machine Name:

-

Liquid Filling 3 Side Sealing Packing Machine

-

Packaged Item:

-

Liquid Paste Jam Sauce Packing

-

Machine Material:

-

304 Stainless Steel

-

Packing Range:

-

3-100 g

-

Packing Film Material:

-

Laminated Film,OPP/CPP, PET/PE,etc.

-

Bag Size:

-

L:50-135 mm W:40-120 mm

-

Packing Speed:

-

30-60 Bags/min

-

Control System:

-

Piston Filler

-

Feature:

-

No Leakage & High Reliability, High Efficiency

Quick Details

-

Function:

-

FILLING, Wrapping, Sealing

-

Packaging Type:

-

Bags, Film, Foil, Pouch

-

Packaging Material:

-

Plastic, Paper, Metal

-

Weight (KG):

-

350

-

Voltage:

-

220v

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

JIN HUA TAI

-

Dimension(L*W*H):

-

700*1200*1700 mm

-

Machine Type:

-

Automatic Vertical Packaging Machine VFFS

-

Machine Name:

-

Liquid Filling 3 Side Sealing Packing Machine

-

Packaged Item:

-

Liquid Paste Jam Sauce Packing

-

Machine Material:

-

304 Stainless Steel

-

Packing Range:

-

3-100 g

-

Packing Film Material:

-

Laminated Film,OPP/CPP, PET/PE,etc.

-

Bag Size:

-

L:50-135 mm W:40-120 mm

-

Packing Speed:

-

30-60 Bags/min

-

Control System:

-

Piston Filler

-

Feature:

-

No Leakage & High Reliability, High Efficiency

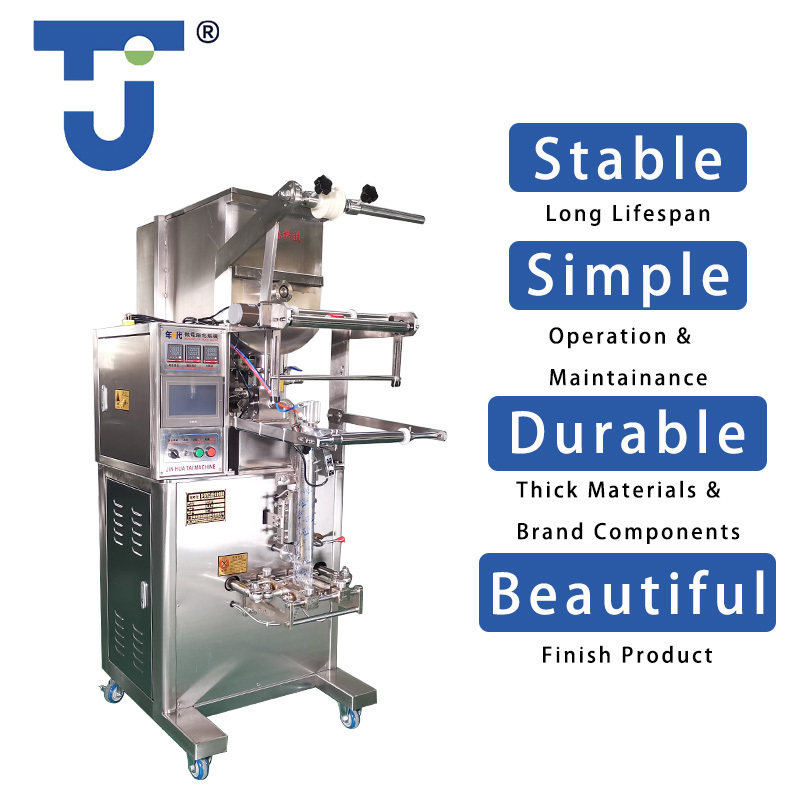

APPLICATION & FEATURE

Mechanical

Liquid Sauce

Horizontal Stirring Packaging Machine (

Three Side Sealing

)

◆APPLICATION

The machine is suitable for packaging various kinds of liquid materials which are used in food, chemical, medicine, condiment, daily necessities. Such as jam, sauce, condiment, drink, oil, yogurt, shampoo, hand sanitizer, etc.

◆FEATURE

1. Stainless steel body, compact structure, stable performance, small footprint, easy maintenance;

2. The cutting of packaging products can be zigzag cutting or scissor type flat cutting;

3. Pump body uses stainless steel, which is environmentally friendly and hygienic;

4. Touch screen operation, simple and easy to understand, easy to operate;

5. Using stepper motor to pull the bag, the precision is accurate, the adjustment is convenient, and the bag length can be adjusted without stopping;

6. Seal tightly to avoid moisture;

7. Clip-on inserted film filling method, the machine can keep working if there is a little static electricity in film;

8. Speed regulation by touch screen,speed control without stopping.

MACHINE DETAIL

|

Product Name

|

Three-Side Sealed Horizontal Stirring Liquid Packaging Machine

|

|

Model

|

DF-50AYH

|

|

Packaged Item

|

Sauce, Jam, etc

|

|

Driven Type

|

Mechanical

|

|

Sealing Type

|

Three-Side Sealed

|

|

Filling System

|

Piston Filler

|

|

Application

|

Food, Beverage, Medical, Chemical

|

|

Bag Type

|

Roll film sachet, pouch

|

|

Film Material

|

Composite Roll film: Metal(AL), Paper, OPP/CPP/PET/PE/PA/EVOH

|

|

Filling Range

|

3-100 g

|

|

Bag Size

|

L:50-135 mm W:40-120 mm

|

|

Packing Speed

|

30-60 Bag/Min

|

|

Voltage

|

220V 50/60HZ

|

|

Total Power

|

2.5 KW

|

|

Weight

|

350 KG

|

|

Machine Body

|

Stainless Steel SUS 304

|

|

Dimension (L*W*H)

|

700*1200*1700 mm

|

FINISHED PRODUCT

MORE HOT MODEL

COOPERATION BRAND

COMPANY PROFILE

Guangdong Jinhuatai Packaging Machiner Technology Co., Ltd.

Guangdong Jinhuatai Packaging Machiner Technology Co., Ltd. is a provincial private technology enterprise integrating the design, production and sales of food packaging equipment.

Since its establishment in 1999, the company has been committed to the R & D, production and sales of food and all kinds of packaging equipment. The products have been used in many fields such as food, washing and medical treatment. At present, there are offices in major large and medium-sized cities in China.

We sincerely welcome domestic and foreign enterprises to come to guide, seek cooperation and development together.

EXHIBITON & CERTIFICATE

Updated Exhibition:

◆ ProPak China 2019

◆ The 101th China Food & Drink Fair 2019

SERVICE & FAQ

Packaging:

We will clear every parts, packed firstly with the film, then put in the standard export wooden case ( Fumigation

Free).

Shipping:

Upon receipt of full payment , delivery date will be in 10-35 days. Shipment cost will depend on the destination, shipment way and the weight of the goods.

After-sale Services:

We will clear every parts, packed firstly with the film, then put in the standard export wooden case ( Fumigation

Free).

Shipping:

Upon receipt of full payment , delivery date will be in 10-35 days. Shipment cost will depend on the destination, shipment way and the weight of the goods.

After-sale Services:

1. Manuals / Videos of machine installation, adjusting, setting, maintenance are available for you.

2. If any problem happens and you can not find out the solutions, Telecom or Online face to face communication available 24 hours.

3. Engineers & technician are available send to your countries for services if you agree to pay the expenditure.

4. The machine will have one year warranty.

FAQ:

Q1: How to find a packaging machine suitable for my product?

Tell us about your product details and packing requirements.

1. Product details (Liquid,Powder,Granule etc.)

2. Bag shape and specification (Length, Width).

3. Packing film material.

4. Net weight of filling product.

Q2: How can I trust you for the first time business ?

We aim to establish a long-term cooperative relationship instead of just doing business once. If you don't trust us, then we can use Alibaba trade assurance service, guarantee your money, and guarantee your machine's on-time delivery and machine quality.

Q3: Is engineer available to serve oversea?

Yes, but the travel fee is paid by you.In order to save your cost, we will send you a video of full details machine installation and assist you till the end.

Q4. How can we make sure about the machine quality after placing the order?

Before delivery, we will send you the pictures and videos for you to check the machine quality.And also you can arrange for quality checking by yourself or by your contacts in China.

Q5: Can you explain me the whole transaction process ?

1. Sign the Contact;

2. Arrange 30% deposit to our factory;

3. Factory arrange production;

4. Testing & detecting the machine before shipping;

5. Inspected by customer or third agency through online or site test;

6. Arrange the balance payment before shipment.

Hot Searches